Cartridge seals, The bearing housing assembly – Viking Pump TSM270: RL41507 Industrial Rotary Lobe User Manual

Page 6

SECTION TSM

270

ISSUE

F

PAGE 6 OF 10

9.Remove the outer cone of the tapered roller bearing. It

might be necessary to thread the bearing housing back

into the bracket. Remove the spacer between the two

cones and the cup of the bearing set.

CAUTION: It is important to keep the bearing together as

a set and in the proper order since the spacer is ground

specifically for those components to provide the proper

preload.

THE BEARING HOUSING ASSEMBLY

10.Remove the inner bearing cone, if it doesn’t slide freely,

reinstall the end cap and capscrews and use a puller

(see figures 6 and 10). The back side of the end cap has

a machined recess to allow puller usage. Slide the inner

spacer (Item #22) off shaft. Repeat the process for the

other bearing housing.

11.Reposition the pump so the bracket is free standing. See

figure 7. Place a lifting strap through the top bearing

bore and support from overhead. Remove the (8) ½”

nuts (Item #26) then remove the bracket. Pull the

bracket off of the dowel pin and studs.

12.Depending on the type of mechanical seal used, make

sure the securing devices to hold or stabilize the

seal while removing from the shaft are in place and

positioned properly. Unlock the setscrews securing the

sleeve to the shaft. Remove the (4) capscrews that hold

each seal in place then pull the seal off the shaft.

13.The lobe and shaft assembly is now ready to pull out of

the casing.

Caution: This assembly weighs 130 pounds and requires

two people or an overhead hoist to handle.

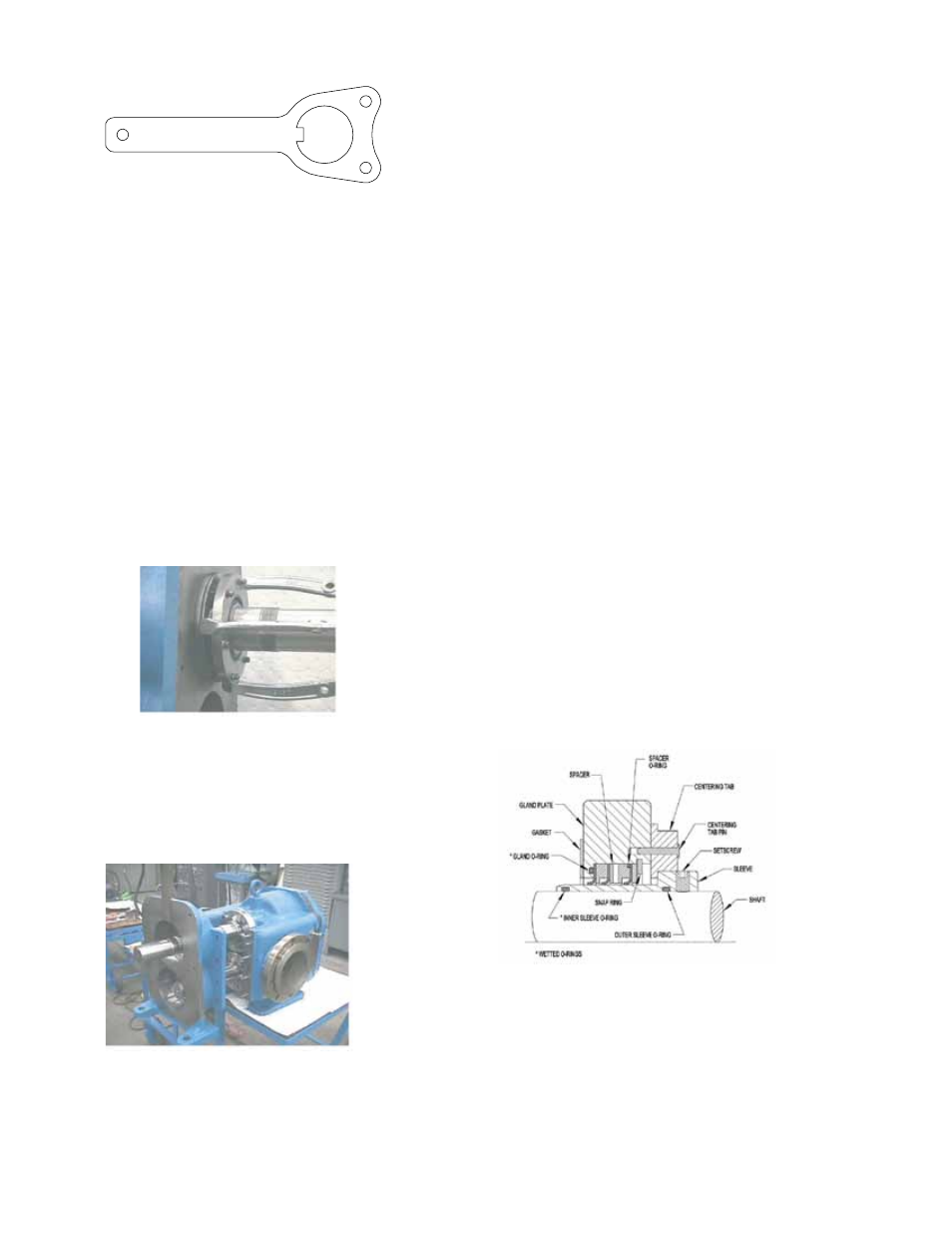

CARTRIDGE SEALS

The standard seals used in this pump are Fluidtec P/S

®

-II

(Figure 8) and are simple to install. Proper care on installation

will help in providing good service life.

Good radial alignment is required for proper operation

of the seals. This is accomplished by use of centering

tabs provided with each seal. Turn the tabs inward when

installing or removing the seal. Turn them outward for

normal operation of the pump.

14.Slide the driver shaft out 10” and have one person

support the assembly. Continue sliding the assembly

out with the other person supporting the opposite end of

the shaft. Repeat these steps for the driven shaft.

15.Inspect the labyrinth seals (Item #21) and lip seals in

each bearing housing. Leave in the housing unless

they show signs of wear or damage (See LABYRINTH

SEAL, page 7).

16.Clean all parts thoroughly and examine for wear or

damage. Check the lip seals, bearings, bushings and

replace if necessary. Check all other parts for nicks,

burrs or excessive wear and replace if necessary.

Pay special attention to the shaft area underneath the

mechanical seal where seal set screws contact.

CAUTION: Do not mix the two bearing cones with

respect to the one piece cup.

17.Wash bearings in clean solvent and blow out with

compressed air. Make sure bearings are clean, then

lubricate with light oil. Check for roughness by placing

the cone on the cup and turning.

Bearing Housing Spanner Wrench

Part No. 2-810-060-375

FIGURE 5

FIGURE 6

FIGURE 7

FIGURE 8