Suggested repair tools, Pump disassembly, Danger – Viking Pump TSM270: RL41507 Industrial Rotary Lobe User Manual

Page 5

SECTION TSM

270

ISSUE

F

PAGE 5 OF 10

4.Straighten out the bearing lockwasher tab on both shafts

(See figure 4). Place a wooden block or brass bar in

between the lobes to block rotation of the top shaft.

Use the spanner wrench (Suggested Repair Tools # 5)

to loosen the locknut. Remove the wooden block and

insert on the opposite side to restrict movement of the

other shaft. Remove the second locknut. Remove both

of the lockwashers.

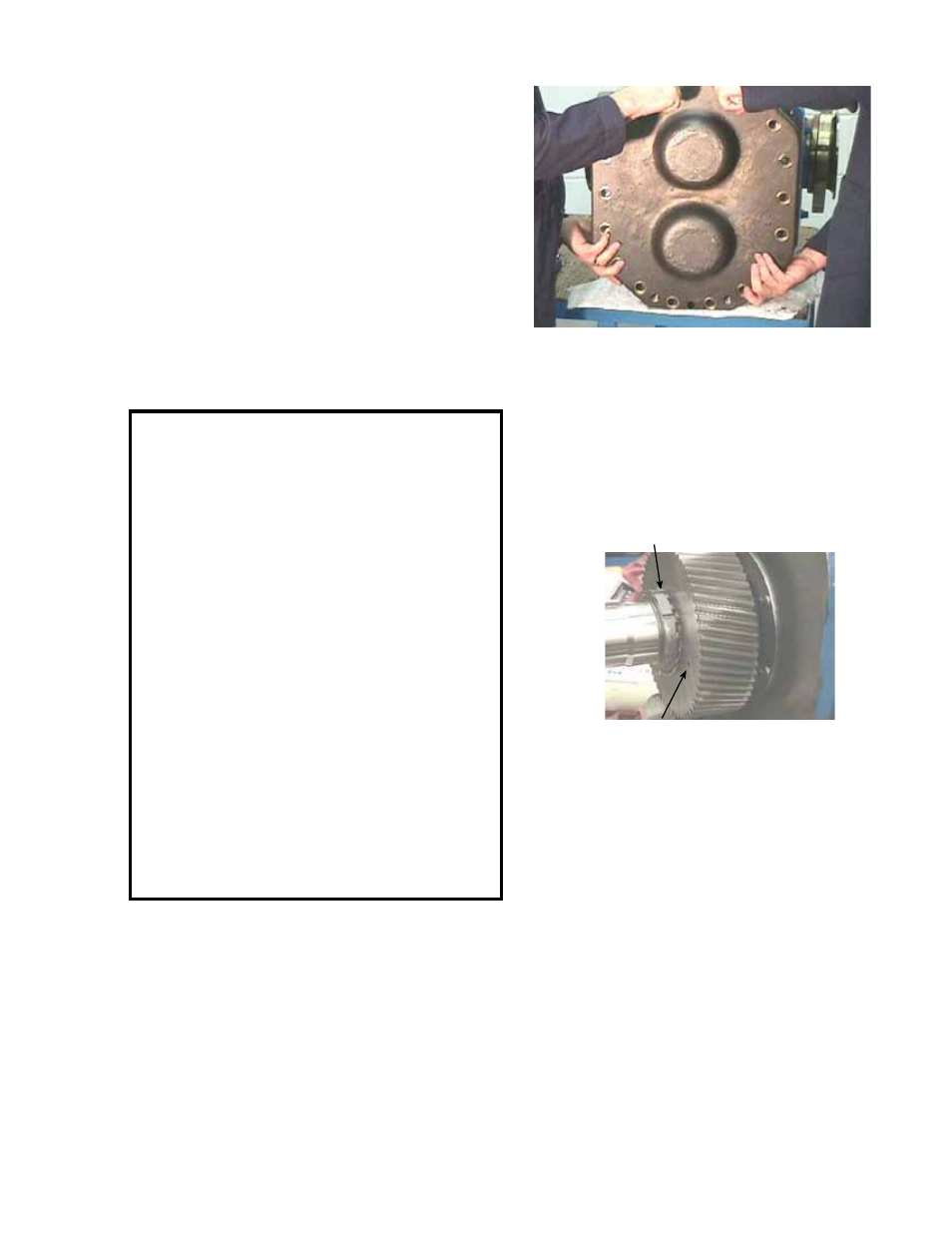

5.Slide the timing gears off the shafts. If the timing gears

do not come off easily, use (3) 1/2“ capscrews as

jackscrews or a bearing puller (See Figure 4).

6.Remove the keys under the gears. (These are special

size keys – do not lose them - standard 5/8” key stock

should not be used)

7.Remove the (4) 1/8”allen head pipe plugs (items #29) on

the sides of the bracket. Loosen the (4) 5/16” set screws

(items #28) that lock the bearing housings in place by 3

full turns.

8.Use the assembly tool shown in Figure 5 to rotate and

remove the bearing housing. The bearing housing

should come out as an assembly. If it does not, remove

the (6) allen head capscrews (Item #13) then the end

cap (Item #17). Slide the outer spacer off the shaft.

SUGGESTED REPAIR TOOLS

The following tools must be available to properly repair

Viking RL pumps. These tools are in addition to standard

mechanics’ tools such as open end wrenches, pliers, screw

drivers, etc. Most items can be obtained from an industrial

supply house.

1. Soft headed hammer

2. Allen wrenches

3. Depth micrometer (0-1” Range)

4. Bearing Locknut Spanner Wrench (Source: #472

J.H. Williams & Co. or equal)

5. Brass bar or wood block

6. Arbor Press

7. 3/4” NC X 6” capscrews (2)

8. Bearing Puller

PUMP DISASSEMBLY

1.Turn the centering tabs on the seals 90° (See Figure 8).

2.Remove the (18) nuts holding the head with a 15/16”

wrench. Carefully slide head off of studs. If head does

not slide freely, insert a dowel pin approx. 1” long into the

¾” tapped holes (one at the top and bottom) then thread

in the ¾” X 6” capscrews (suggested repair tools #2).

CAUTION: The head weighs 125 pounds and will require

two people to handle. See Figure 3.

FIGURE 3

Bearing Lockwasher Tabs

3/8” Jackscrew Holes

3.Drain oil in the gear case by removing the pipe plug (item

#1). Remove (6) ½ “ capscrews then carefully slide gear

case off driver shaft. There is one dowel pin that might

restrict removal.

FIGURE 4

DANGER !

Before opening any Viking pump liquid chamber

(pumping chamber, reservoir, etc.) be sure:

1. That any pressure in the chamber has been

completely vented through the suction or

discharge lines or other appropriate openings or

connections.

2. That the driving means (motor, turbine, engine,

etc.) has been “locked out” or made non-

operational so that it cannot be started while work

is being done on pump.

3. That you know what liquid the pump has been

handling and the precautions necessary to

safely handle the liquid. Obtain a material safety

data sheet (MSDS) for the liquid to be sure these

precautions are understood.

4. That

the timing gearbox to cool before handling

the pump. The oil will become very hot during

normal operation. Allow the timing gearbox oil.

Failure to follow above listed precautionary

measures may result in serious injury or death.