Connecting torch, Spare parts label, Torch parts selection – Tweco SL100 User Manual

Page 2

Manual 0-2880

2

NOTE

Power Supply characteristics will determine material

thickness range.

D. Torch Ratings

SL60 Torch Ratings

Ambient

Temperature

104° F

40° C

Duty Cycle

100% @ 60 Amps @ 400 scfh

Maximum Current

60 Amps

Voltage (Vpeak)

500V

Arc Striking Voltage

7kV

SL100 Torch Ratings

Ambient

Temperature

104° F

40° C

Duty Cycle

100% @ 100 Amps @ 400 scfh

Maximum Current

100 Amps

Voltage (Vpeak)

500V

Arc Striking Voltage

7kV

E. Type of Cooling

Combination of ambient air and gas stream through

torch.

F. Gas Requirements

SL60 and SL100 Torch Gas Specifications

Gas (Plasma and Secondary)

Compressed Air

Operating Pressure

Refer to NOTE

60 - 75 psi

4.1 - 5.2 bar

Maximum Input Pressure

125 psi / 8.6 bar

Gas Flow (Cutting and Gouging)

300 - 500 scfh

(142 - 235 lpm)

!

WARNING

This torch is not to be used with oxygen (O

2

).

NOTE

Operating pressure varies with torch model, operat-

ing amperage, and torch leads length. Refer to gas

pressure settings chart for each model.

G. Direct Contact Hazard

For exposed tip the recommended standoff is 1/8" - 1/4"

(3 - 6.4 mm).

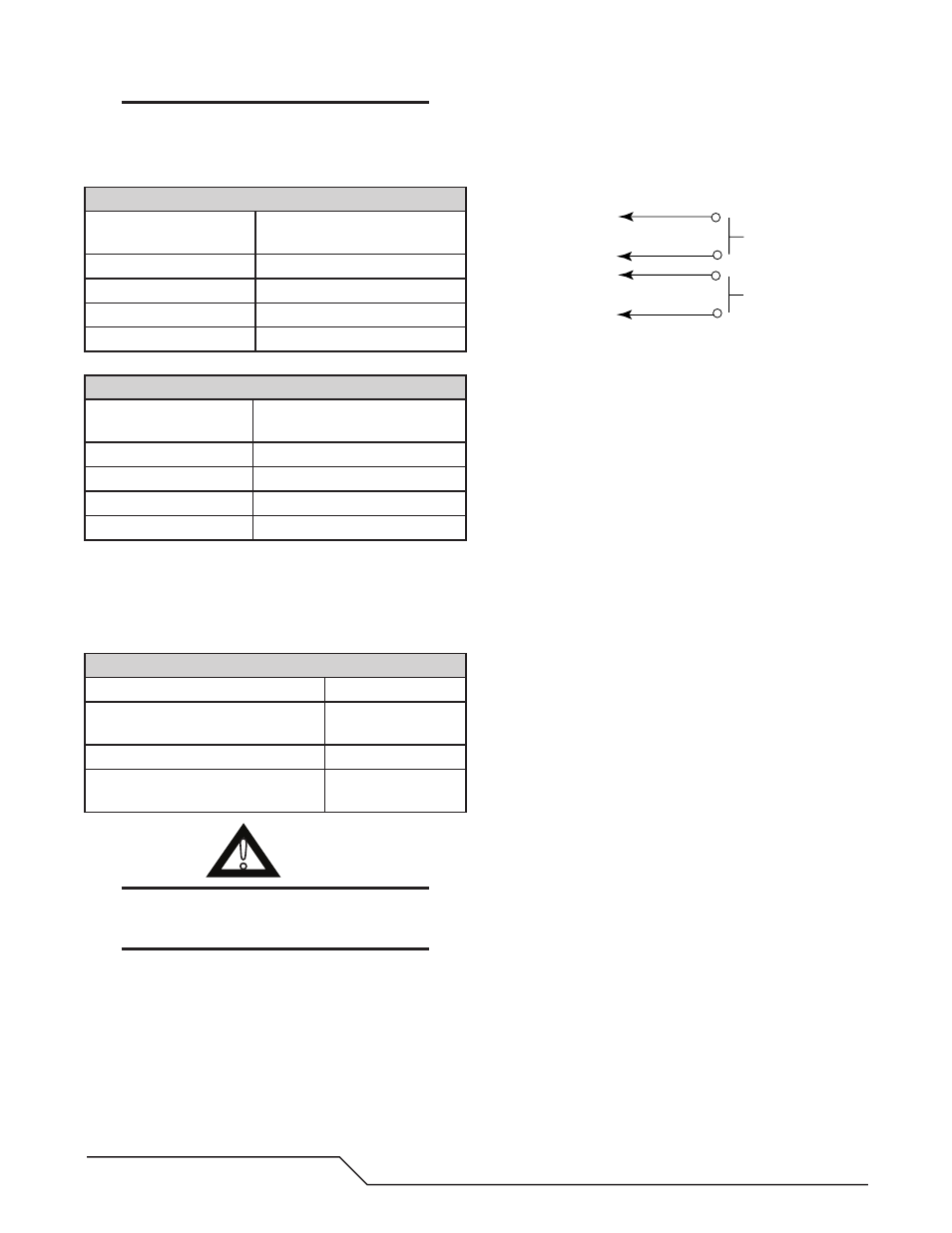

H. Parts-In-Place (PIP) Circuit - 12 vdc

The torch and leads include circuitry called Parts-

In-Place (PIP). This circuit includes a switch located

at the torch head. The shield cup closes this switch

when properly installed. The torch will not operate

if this switch is open.

A-02997

Torch Trigger

PIP Switch

Shield Cup

To Control

Cable Wiring

Torch Switch

Connecting Torch

There are two types of connection for the Torch Leads.

One type uses the Victor Thermal Dynamics ATC connec-

tor. The other uses O2B connections for gas and circuitry.

Both types require an adapter kit sold separately.

ATC Connectors

Follow the instructions provided with the adapter kit to

connect the adapter to the power supply.

Inspect the halves of the ATC Connector. Align the male

connector with the female receptacle and push them

together by hand until they seat fully. Turn the Locking

Ring until it pulls the halves of the connector together

fully. Do not use tools to tighten the connector. If there

is any resistance to the ring turning, pull the halves of the

connector apart, realign the inner components, ensure

that the threaded components are aligned, and push the

halves of the connector together again.

O2B Connectors

Leads with O2B connectors are connected to the power

supply using adapter kits sold separately. Follow the

instructions provided with the adapter kit to connect the

gas and electrical lines to the power supply.

Spare Parts Label

The parts kit provided with the torch includes an adhe-

sive label. Select the small perforated section showing

the appropriate pressure setting for the amperage output

and leads length to be used with this torch. Refer to the

charts. Apply this section in the 'Gas Supply' area of the

label under the 'Recommended Operating Pressure' text.

Discard any pressure setting sections of the label that will

not be used. Apply the large label to the power supply,

where the operator can see it for easy reference.

Torch Parts Selection

Refer to the Consumables Selection Chart for the various

torch parts for the application and operation.