Shield – Tweco XT-301 Torch Data for OEM use w- Auto-Cut 30O2 AD User Manual

Page 29

Manual 0-4832 Rev AD

8-29

TORCH DATA for AutoCut O

2

Aluminum

200A

H35 Plasma / N

2

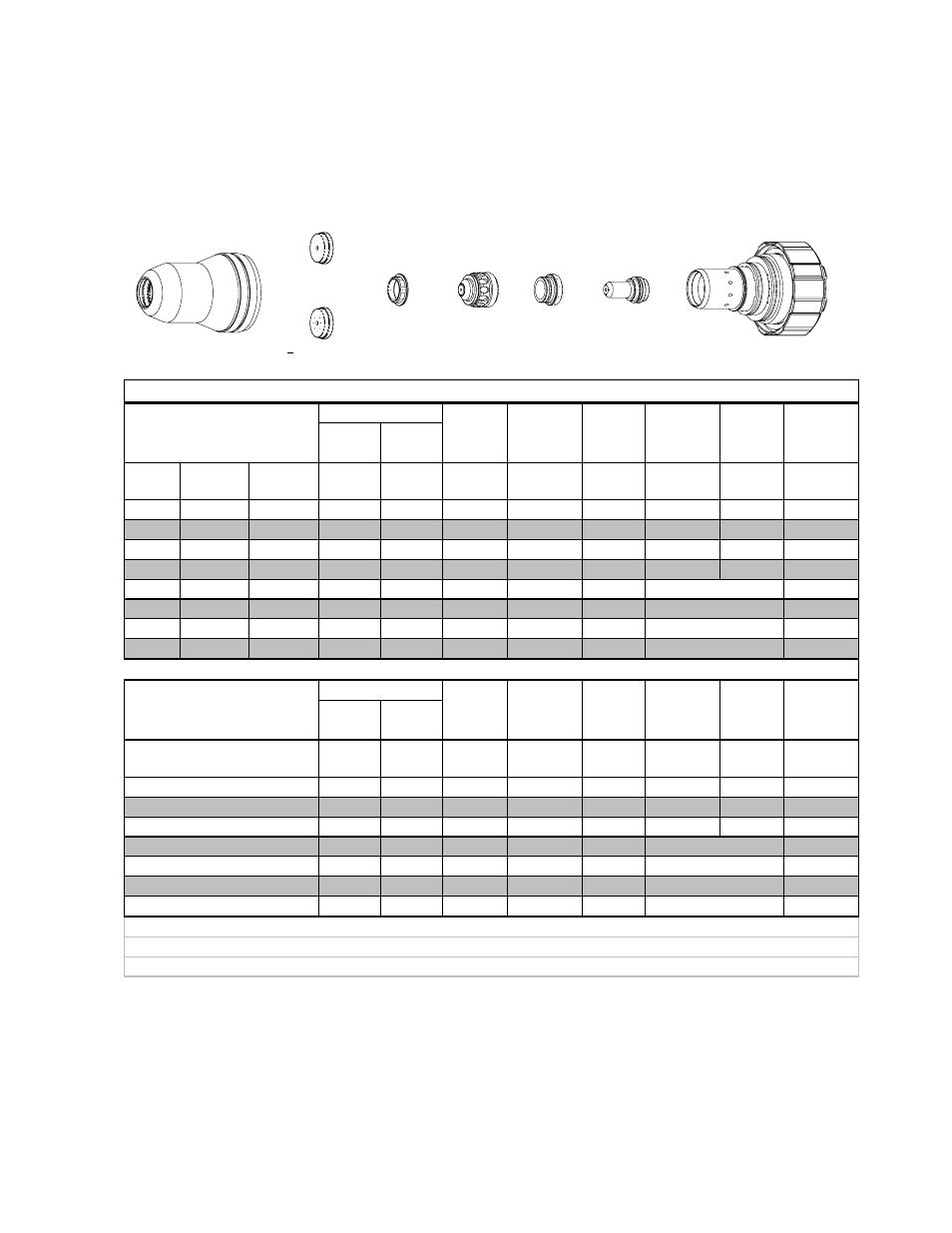

Shield **

36-1273

Shield Cup

36-1016

Shield Gas

Distributor

Tip

36-1058

Art # A-07611

Plasma Gas

Distributor

36-1043

Electrode

36-1087

Cartridge

36-1020

Shield Cap

< 1” (25mm)

1” + (25mm)

36-1032

36-1031

>

Plasma

(H35)

Shield

(N

2

)

(ga)

(in)

inch

(PSI)

(PSI)

Volts

(in)

±0.005

(ipm)

(in)

(sec)

(in)

1/2

0.5

70

100

155

0.300

150

0.350

0.2

0.163

5/8

0.625

70

100

160

0.300

110

0.350

0.3

0.169

3/4

0.75

70

100

166

0.300

70

0.400

0.4

0.177

7/8

0.875

70

100

171

0.350

55

0.450

0.5

0.192

1

1

70

100

177

0.350

40

0.196

1 1/4

1.25

70

100

181

0.350

32

0.180

1 1/2

1.5

70

100

188

0.350

25

0.190

2

2

70

100

190

0.350

15

0.195

Plasma

(H35)

Shield

(N

2

)

(Bar)

(Bar)

Volts

(mm)

±0.1

(mm/min)

(mm)

(sec)

(mm)

4.8

6.9

155

7.6

3810

7.6

0.2

4.3

4.8

6.9

159

7.6

3070

8.9

0.3

4.3

4.8

6.9

167

8.0

1660

10.5

0.4

4.6

4.8

6.9

176

8.9

1060

5.0

4.8

6.9

181

8.9

810

4.6

4.8

6.9

188

8.9

640

4.8

4.8

6.9

190

8.9

400

4.9

200A Aluminum (H35/N

2

)

Material

Thickness

Cut Flow

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height*

Pierce

Delay

Kerf Width

@ Rec.

Speed

Edge Start

Edge Start

Edge Start

Edge Start

Material

Thickness

Cut Flow

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height*

Pierce

Delay

Kerf Width

@ Rec.

Speed

(mm)

12

15

20

25

Edge Start

32

Edge Start

**Requires Firmware version 3.2 or higher for the Power Supply and 2.1 or higher for the Gas Control Box.

* Lock pierce height for first 0.5" to 1" of cutting to avoid torch hitting the pierce metal puddle.

Slightly decreasing the shield gas pressure minimizes dross on aluminum cutting

38

Edge Start

50

Edge Start