Tweco 9-9435 User Manual

General description, Specifications, Scope of instructions

March 6, 2006

1

Manual 0-4738 Rev. AA

82 Benning Street, West Lebanon, NH 03784 USA

(603) 298-5711 • www.thermal-dynamics.com

Manual 0-4738

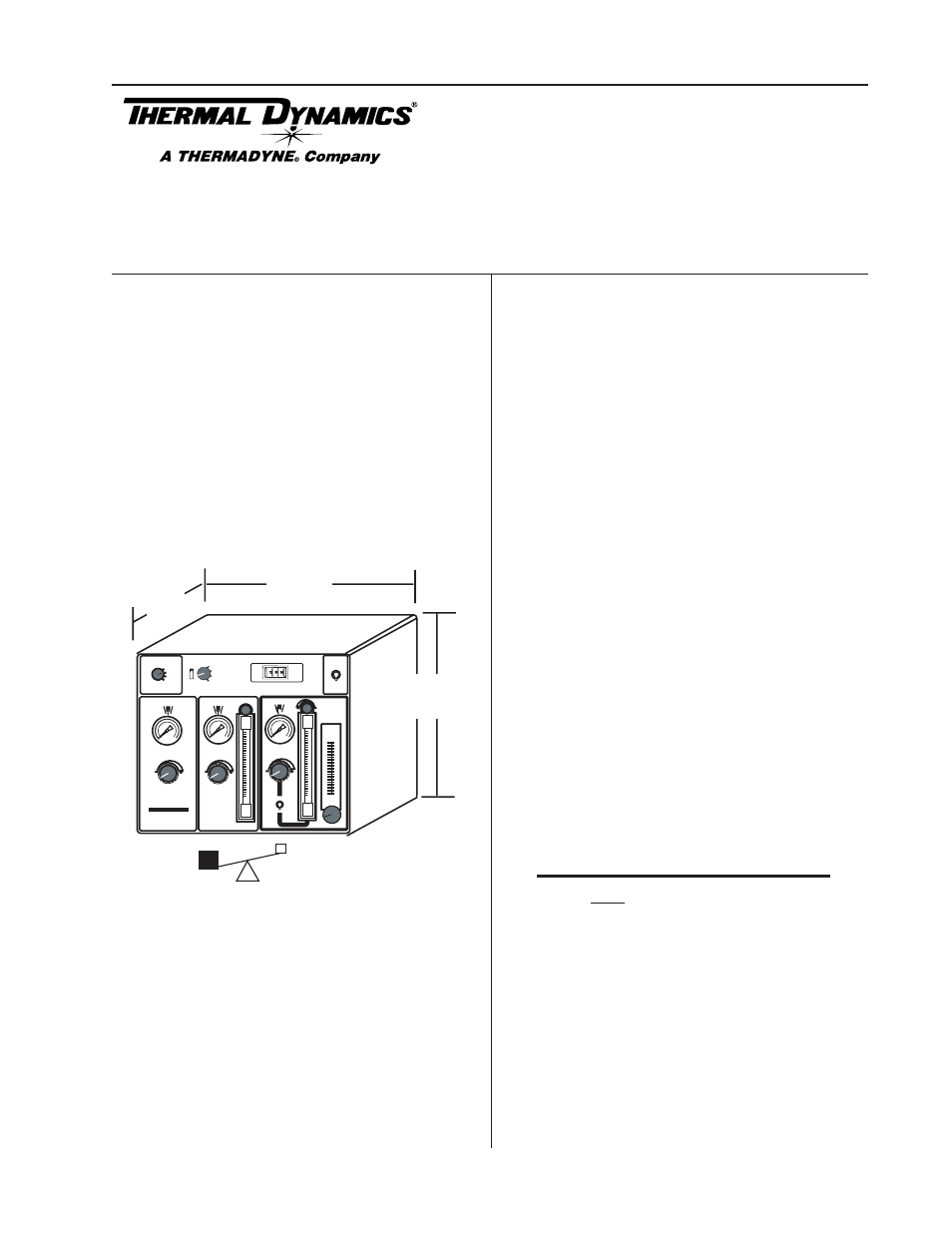

Gas Control Module

Model GCM-2000

Catalog # 9-9435

Installation Instructions

General Description

This control Module is for use only with Thermal Dy-

namics Auto-Cut

®

20O2 and Auto-Cut

®

30O2 power

supplies and the Thermal Dynamics XT

TM

-301 torch.

Do not use this module with any other equipment.

The Control Module includes front panel selector

switches and flow and pressure controls and gauges.

All connections to the module are made to the rear

panel.

Specifications

40 lb / 18 kg

16.25"

413 mm

11"

279 mm

14.25"

362 mm

Art # A-07282

PREFLOW

H

2

O

MIST

PLASMA

SHIELD

PRESSURE

PLASMA

POWER SUPPLY

GAS

FLOW

ENABLE

DISABLE

MODE

RUN

SET PREFLOW

SET PLASMA

& SHIELD

TEST

9

9

GCM

2000

Automated

Plasma Cutting System

AMPS

Thermal Dynamics

GAS

O

2

- AIR

H35 - N

2

AIR - AIR

N

2

- H

2

O

Scope of Instructions

These instructions cover installation of the gas control

module only. Operational instructions are provided in

the Auto-Cut

®

20O2 and Auto-Cut

®

30O2 power sup-

ply manuals.

Installation

Select a clean, dry location with good ventilation and

adequate working space around all components.

All gas inputs and two control cables attach to the rear

panel. A fiber-optic control cable passes through the

rear panel and connects to a printed circuit board in-

side the module. There must be adequate space be-

hind the module for these hose and cable connections

without crimping.

The Gas Control Module must be installed in a suitable

location where it is easily accessible to the system op-

erator. The unit must be mounted to a flat horizontal

surface. If the module is mounted to a gantry or any

other support subject to vibration or motion, the in-

staller must fasten the module to the support securely.

The module should be located as far away as possible

from the Arc Starter due to electromagnetic interfer-

ence. It is acceptable to locate the control cable in the

same track as the cables from the Arc Starter.

The module includes feet which lift the bottom panel

off the mounting surface. There are ventilation holes

on the bottom panel; the space between the bottom

panel and the mounting surface must remain open for

ventilating air to enter the module. Louvers on the back

panel of the module must also remain unblocked, for

the free passage of ventilating air.

NOTE

The unit must be mounted so that the Flowmeters

are plumb. If the Flowmeters are not plumb,

incorrect flow indications may occur.

© 2006, Thermadyne Corp.