Anti-spatter mist applicator – Tweco QRM-100 User Manual

Page 11

Anti-spAtter mist ApplicAtor

3-7

SM-QRM-100

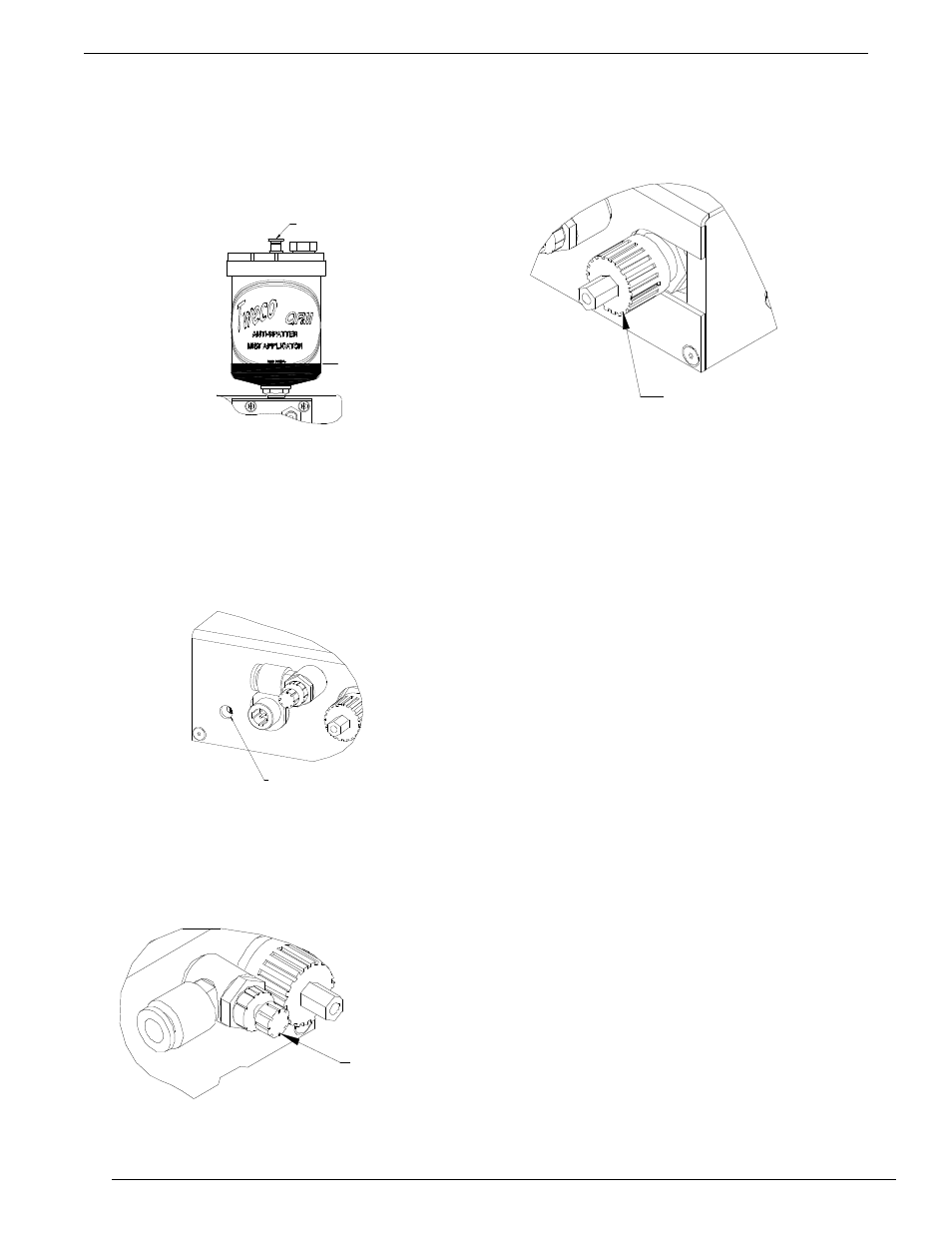

10. Fill the reservoir with the Protex

®

Select Anti-Spatter

Compound. A minimum of 3 ounces must be in the

reservoir at all times. Refer to Figure 6.

IMPORTANT: Be sure the air vent is “OPEN” before

operating the Anti-Spatter Mist Applicator as shown

in Figure 6.

3 OUNCES AT ALL

TIMES

AIT VENT

Figure 6: Callout in Reservoir

11. Turn on the air supply, regulated to 80 to 120 psi, to

the unit.

12. Set the pulse adjustment to the maximum setting of

200 pulses per minute by rotating the adjustment

screw clockwise until it stops. Refer to Figure 7.

PULSE ADJUSTMENT

Figure 7: Pulse Adjustment

13. Turn the air flow adjustment screw to deliver the

maximum flow, by rotating the control valve knob

counter-clockwise until it stops. Refer to Figure 8.

AIR SPEED

CONTROL VALVE

Figure 8: Air Speed Control valve

14. Set the volume adjustment knob all of the way

clockwise. The control knob must be pulled out to

allow this adjustment to be completed. Refer to

Figure 9.

VOLUME CONTROL KNOB

Figure 9: Volume Control Knob

15. Located on the output side of the unit is an access

hole allowing the unit to be manually purged. Insert a

round object through the hole to activate the solenoid

valve by pressing the small button inward.

16. Hold the solenoid valve open until anti-spatter

compound can be seen coming out of the nozzle. This

procedure will saturate both the output air hose and

the torch body and cable assembly purge line.

17. Reset the pulse generator to about 25 pulses per

minute and adjust the airflow as needed.

18. Adjust the volume adjustment knob to obtain the

desired amount of compound residue coverage

on the nozzle, tip and diffuser by rotating counter

clockwise.

19. Turn off the signal.

20. Activate the designated output to the unit at the desired

position in the welding program to use the unit in an

automatic cycle.

21. Monitor the welding process to verify that the proper

amount of anti-spatter compound is being supplied

to prevent weld spatter buildup in the nozzle, tip and

diffuser area.

22. If more anti-spatter is required, increase the number

of pulses or volume of the anti-spatter compound.

inStAllAtion And opeRAtion