Conductor tube alignment fixture – Tweco QCT-1 User Manual

Page 12

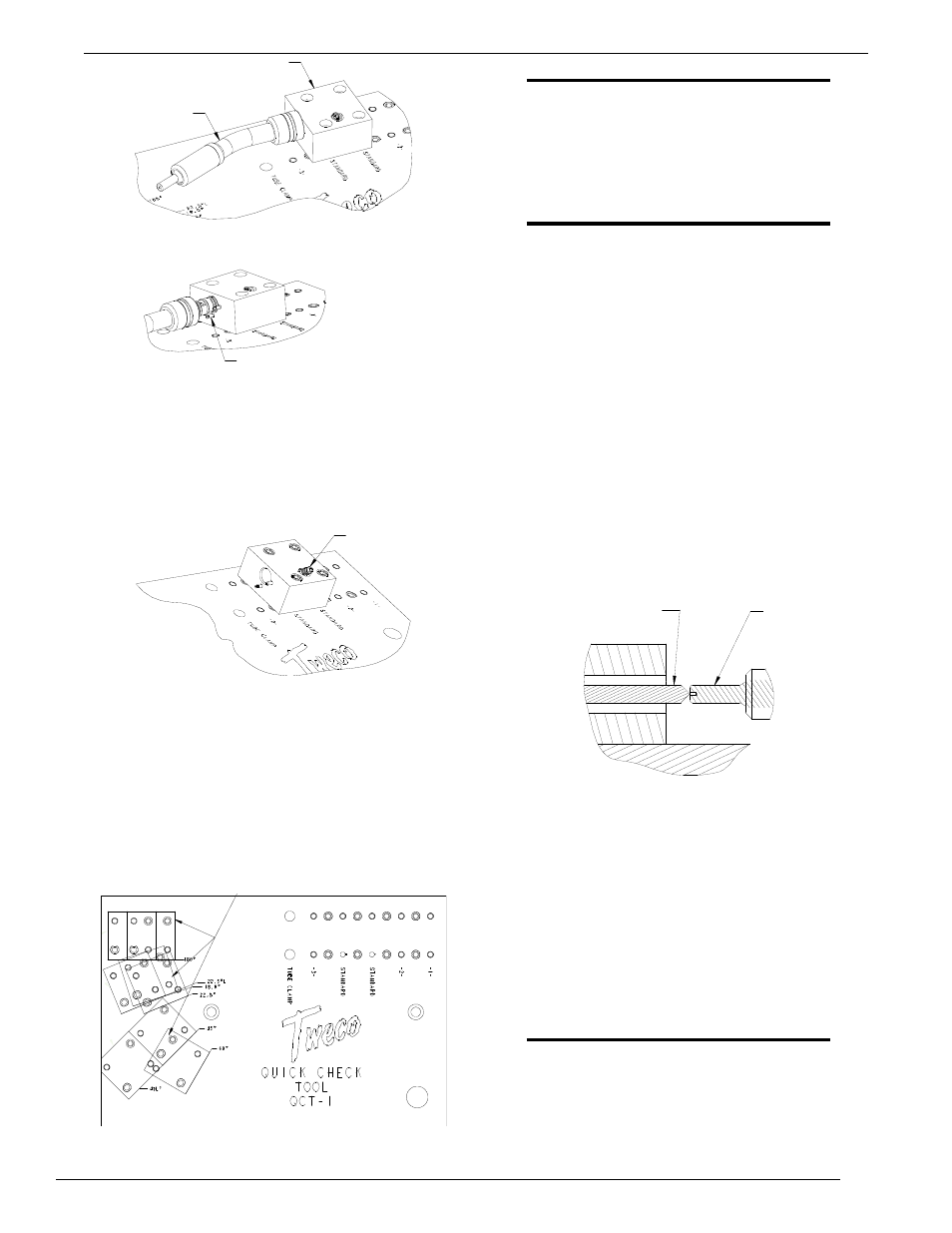

CONDUCTOR TUBE ALIGNMENT FIXTURE

3-8

QCT-1

inSTAllATion And opeRATion

REAR ALIGNMENT

BLOCK ASSEMBLY

CONDUCTOR TUBE

ASSEMBLY

STAINLESS STEEL PINS

Figure 10: Conductor Tube/rear Alignment Block

Assembly

9. Insert the factory supplied 5/32” allen wrench into the

conductor tube locking screw on the rear alignment

block assembly. Rotate the screw clockwise until the

conductor tube is held in place. Refer to Figure 11.

CONDUCTOR TUBE

LOCKING SCREW

Figure 11: Conductor Tube Locking Screw on Rear

Alignment Block Assembly

10. Remove the two 5/16”-18 socket head cap screws

from the front alignment block assembly.

11. Locate the assembly according to the conductor tube

assembly degree of bend. (eg., if the conductor tube

bend equals 22.5°, set the front alignment assembly in

the 22.5° location on the fixture). Refer to Figure 12.

ALIGNMENT

LOCATIONS

Figure 12: Outline of Front Alignment Block Locations

NOTE

The front alignment block can be positioned

in the following positions on the alignment

fixture:

180° - 18° - 22.5° - 22.5°l - 45° - 45°l

- 60°

NOTE

There are two bullet nose dowel pins pressed

into position on the under side of the front

alignment block assembly. The dowel pins

must be aligned with the drill bushings that

are in the fixture plate.

12. Secure the front alignment block into position with the

5/16”-18 socket head cap screws removed in Step 10.

13. While holding the alignment sleeve assembly on the

front alignment block, slide the alignment sleeve pin

forward until it contacts the brass alignment pin on the

conductor tube.

14. Verify that the machined point on the alignment sleeve

pin is centered to the small hole in the brass alignment

pin. If the alignment sleeve pin is centered properly, the

alignment sleeve will slide over the brass alignment pin.

This indicates that no adjustments would be required on

the conductor tube assembly. Refer to Figure 13.

Figure 13: Alignment Sleeve Pin and Brass Alignment Pin

BRASS

ALIGNMENT

PIN

ALIGNMENT

SLEEVE PIN

15. Remove the front alignment block assembly from the

fixture plate by removing the two 5/16”-18 socket

head cap screws.

16. Remove the conductor tube assembly from the rear

alignment block assembly by rotating the conductor

tube locking screw counterclockwise.

17. Remove the nozzle spacer and the brass alignment pin

from the conductor tube assembly and replace these

items with the standard diffuser, tip, and nozzle.

NOTE

on the QTRW series conductor tube assemblies,

be sure the insulator ring is in place between

the conductor tube and diffuser.

18. The conductor tube assembly is now ready to be put

into operation.