Conductor tube alignment fixture – Tweco QCT-1 User Manual

Page 10

CONDUCTOR TUBE ALIGNMENT FIXTURE

3-6

QCT-1

SECTION 3:

INSTALLATION AND OPERATION

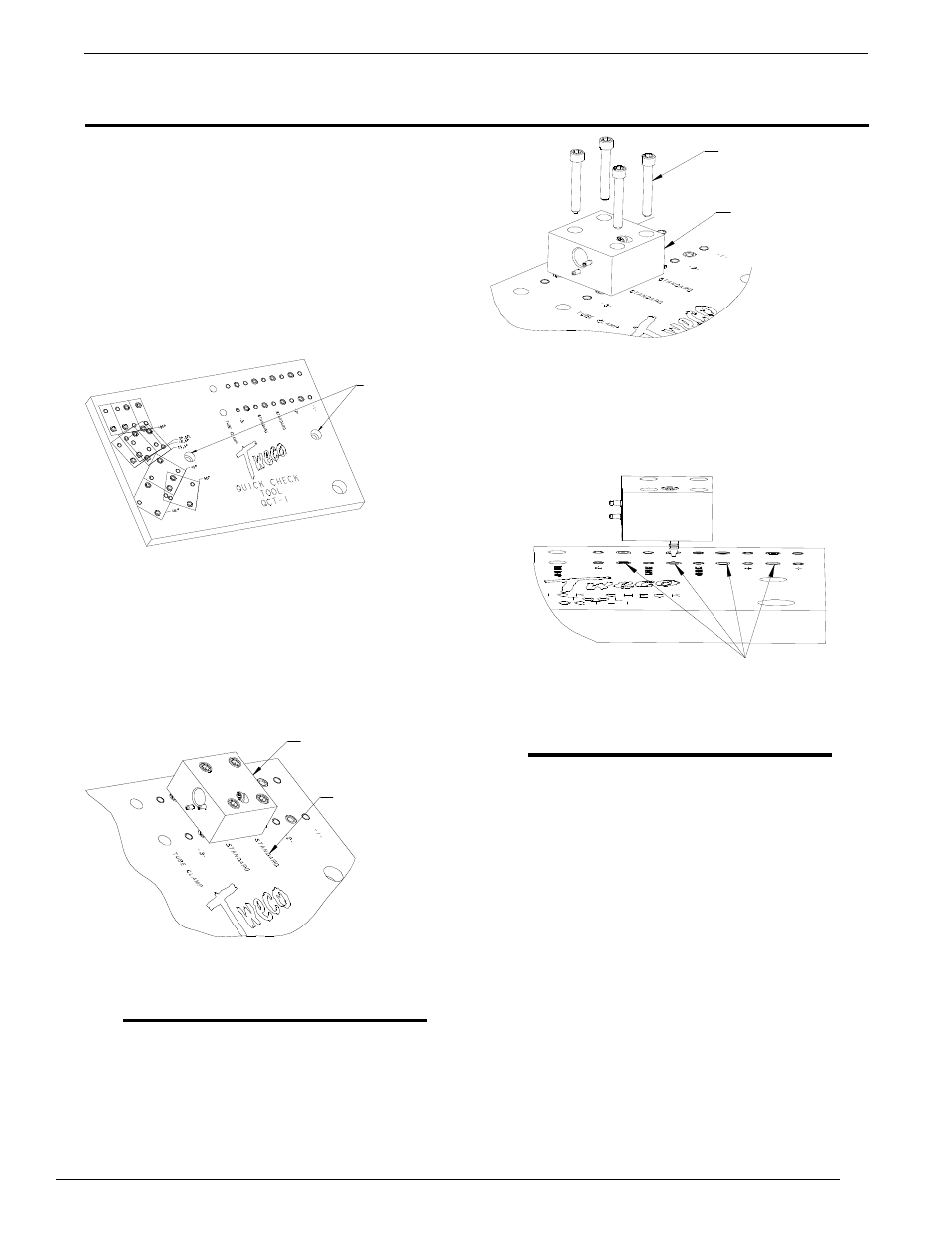

1. Remove the QCT-1 alignment fixture from the

wooden shipping crate. Check to ensure all items

shown in Figure 1 are located and identified. If any of

the component parts are missing, please notify the

local Tweco Welding Distributor or Tweco Products

Customer Service Department at 1-800-426-1888.

2. Mount the alignment fixture to a solid worktable within

close proximity of the robot cell. The fixture base has

two 1/2” (12,70mm) holes, counter bored to accept

a 1/2” socket head cap screws (not supplied). Refer

to Figure 2.

MOUNTING

HOLES FOR 1/2”

SOCKET HEAD

CAP SCREW

Figure 2: Fixture Mounting

The rear alignment block assembly is positioned

and set in the “STANDARD” location on the fixture.

This location will allow any of the standard QTR and

QTRW series conductor tubes to be adjusted without

relocating the rear alignment block assembly. Refer

to Figure 3.

REAR ALIGNMENT BLOCK

ASSEMBLY

MARKED “STANDARD”

FOR POSITIONING

Figure 3: Rear Alignment Block Assembly in Standard

Position

NOTE

if the conductor tube assembly is not a

“STAndARd”, relocate the rear alignment

block assembly by following the steps listed

below.

A. Remove the four 5/16”-18 socket head cap screws

on the alignment block assembly. Refer to Figure 4.

5/16-18” MOUNTING

SCREWS

REAR ALIGNMENT

BLOCK ASSEMBLY

Figure 4: Rear Alignment Block Assembly and Mounting

Screws

B. The fixture plate allows the rear alignment block

assembly to be moved in 1.525” (38,74mm)

increments. Refer to Figure 5.

BUSHINGS

Figure 5: Bushing Location for Rear Alignment Lock

Assembly

NOTE

There are two bullet nose dowel pins pressed

into position on the under side of the rear

alignment block assembly. The dowel pins

must be aligned with the drill bushings that

are in the fixture plate.

C. Position the rear alignment block assembly to

meet your specific requirements.

D. Re-insert and tighten the 5/16”-18 socket

head cap screws into the rear alignment block

assembly.

3. Remove the gas nozzle, diffuser and contact tip from

the conductor tube assembly.

4. Select the correct alignment pin for the specific

conductor tube assembly being adjusted. Thread and

wrench tighten this alignment pin on the conductor

tube assembly. Refer to Figure 6 and Table 1.

inSTAllATion And opeRATion