Tweco FP-165 Mini MIG User Manual

Page 25

FIREpOwER Fp-125, 135, 165

INSTALLATION

Manual 0-5123

3-4

Installation

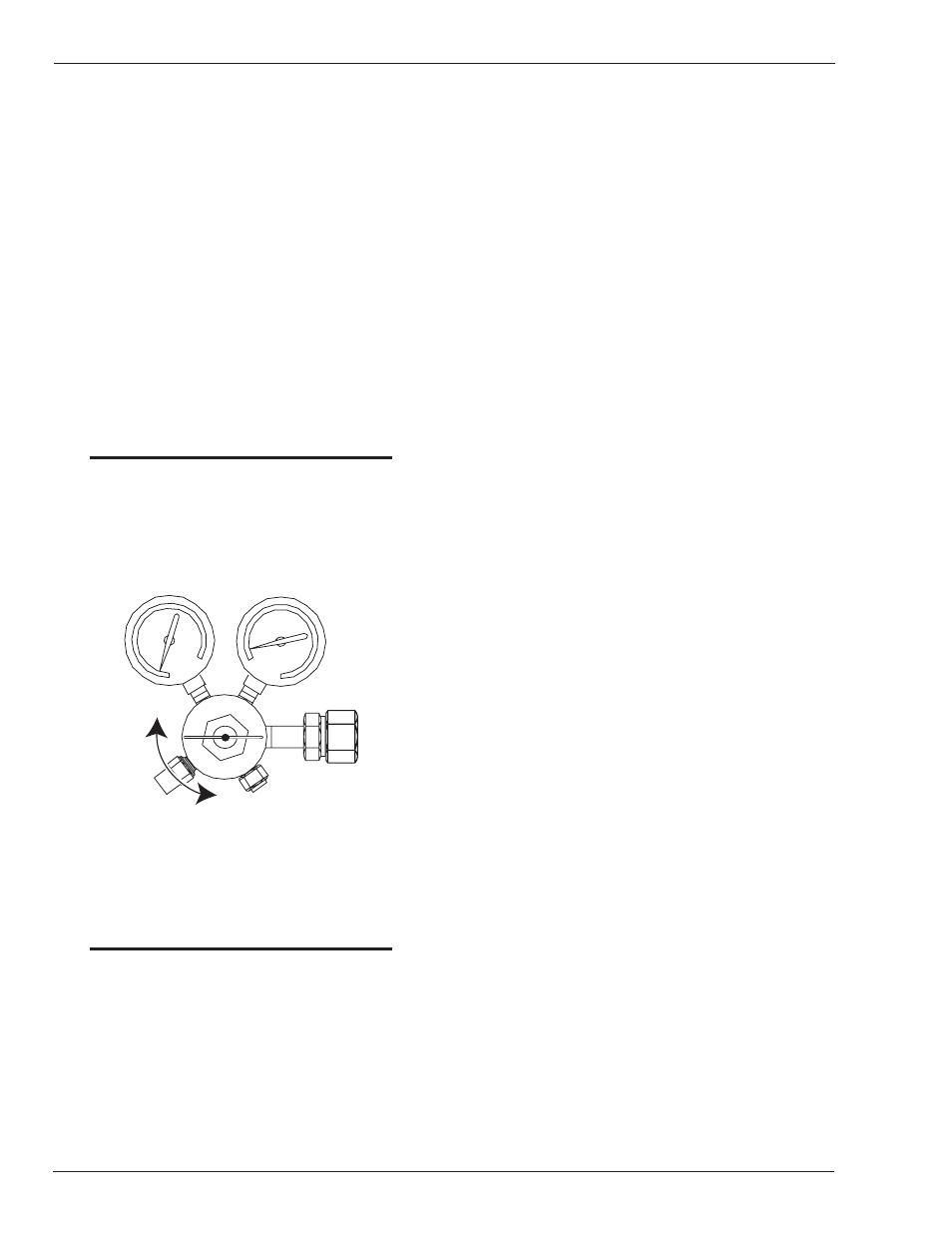

Adjusting Regulator

Adjust control knob of regulator to the required flow rate,

indicated on gauge dial. (Refer to Figure 3-2 and data

charts. Approx. 20 CFH)

The gas flow rate should be adequate to cover the weld

zone to stop weld porosity. Excessive gas flow rates may

cause turbulence and weld porosity.

Argon or argon based gas flow rates:

- Workshop welding: 20-30 CFH

- Outdoors welding: 30-40 CFH

Helium based or CO2 gas flow rates:

- Workshop welding: 30-40 CFH

- Outdoors welding: 40-50 CFH

NOTE

All valves downstream of the regulator must

be opened to obtain a true flow rate reading

on the outlet gauge. (Welding power source

must be triggered) Close the valves after the

pressure has been set.

Art # A-07280

Figure 3-2: Adjusting flow rate. Illustration for

Reference Only.

Refer to section 4.15 for suggested gas / filler metal

combinations.

NOTE

The regulator/flowmeters used with argon-

based and carbon dioxide shielding gases are

different. The regulator/flow meter supplied

is for argon based shielding gases. If carbon

dioxide is to be used a suitable carbon dioxide

regulator/flow meter will need to be fitted.

Two types of gas are generally used with Gas Metal Arc

Welding (GMAW) of thin gauge sheet steel. A mixture of

75% Argon and 25% Carbon Dioxide (CO2) is recom-

mended, Carbon Dioxide (CO2) can also be used.