Weldskill 170 hf inverter – Tweco 170 HF Weldskill User Manual

Page 34

WELDSKILL 170 HF INVERTER

4-12

April 23, 2008

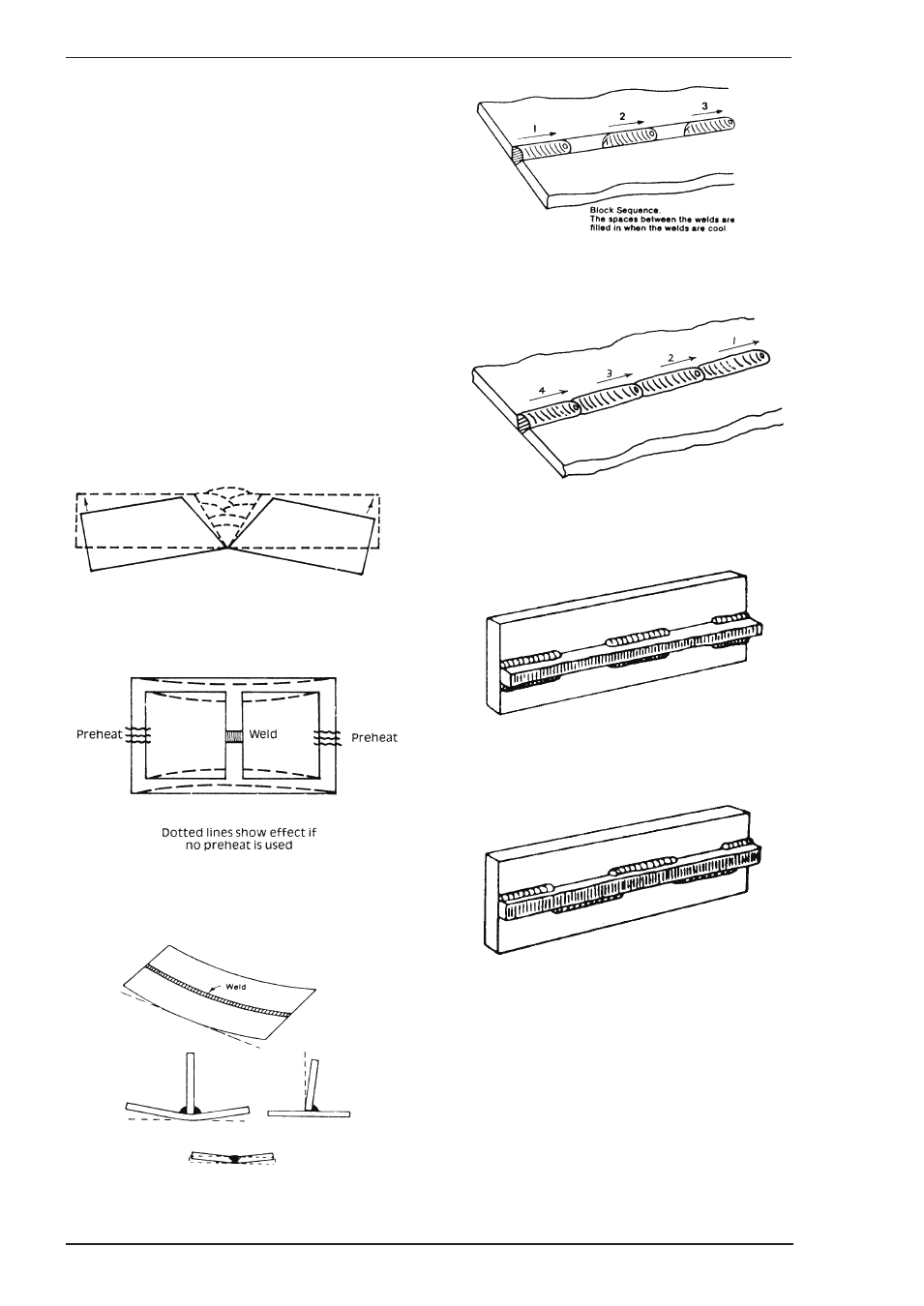

D. Presetting

It is possible in some cases to tell from past

experience or to find by trial and error (or less

frequently, to calculate) how much distortion will take

place in a given welded structure. By correct pre-

setting of the components to be welded,

constructional stresses can be made to pull the parts

into correct alignment. A simple example is shown in

Figure 4-22.

E. Preheating

Suitable preheating of parts of the structure other than

the area to be welded can be sometimes used to

reduce distortion. Figure 4-23 shows a simple

application. By removing the heating source from b

and c as soon as welding is completed, the sections

b and c will contract at a similar rate, thus reducing

distortion.

Art # A-07710

Figure 4-25: Welding sequence

Art # A-07711

Figure 4-26: Step back sequence

Art # A-07712

Figure 4-27: Chain intermittent welding

Art # A-07713

Figure 4-28: Staggered intermittent welding

Art # A-07707

Figure 4-22: Principle of presetting

Figure 4-23: Reduction of distortion by preheating

Art # A-07708

Art # A-07709

Figure 4-24: Examples of distortion