Transtig 170ti – Tweco 170Ti Transtig User Manual

Page 21

TRANSTIG 170Ti

Manual 0-5279

3-3

INSTALLATION, OPERATION AND SETUP

bonding the workpiece to earth may reduce emissions in some, but not all instances. Care should be

taken to prevent the earthing of the workpiece increasing the risk of injury to users, or damage to other

electrical equipment. Where necessary, the connection of the workpiece to earth should be made by

direct connection to the workpiece, but in some countries where direct connection is not permitted,

the bonding should be achieved by suitable capacitance, selected according to national regulations.

6. Screening and Shielding

Selective screening and shielding of other cables and equipment in the surrounding area may alleviate

problems of interference. Screening the entire welding installation may be considered for special

applications.

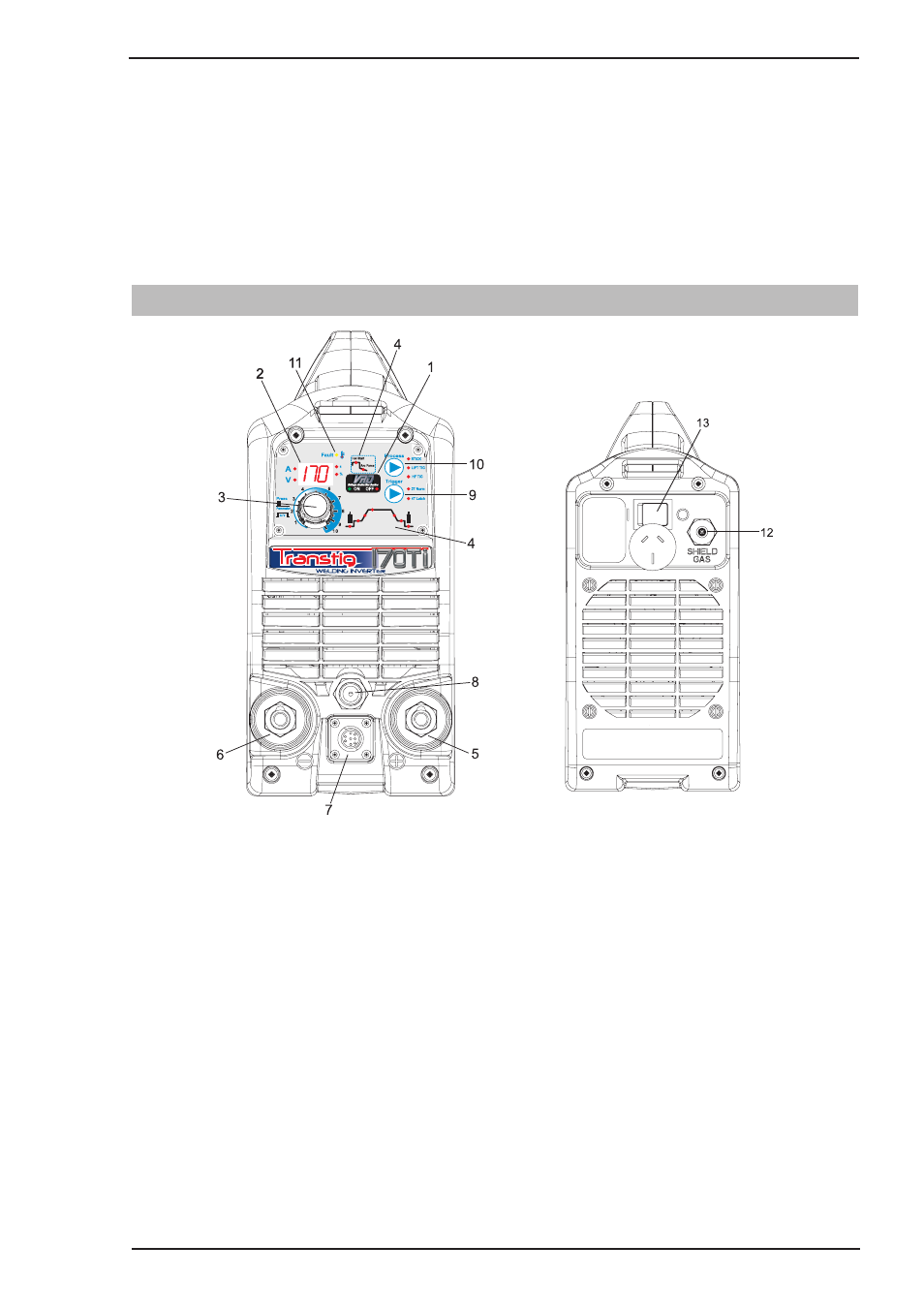

3.06 Transtig 170Ti Power Source Controls, Indicators and Features

A-11694

A-11646

Figure 3-1: Front Panel

Figure 3-2: Rear Panel

1. VRD ON/OFF Indicator Lights

A VRD (voltage reduction device) is a hazard reducing device designed to reduce electric shock hazards

present on the output of welding power source when operating in MMAW (stick) mode. Note that the

presence of VRD should not be used as a substitute for the use of appropriate safety practices as indicated

in section one of this manual.

Both the green and red indicator lights only operate in MMAW (stick) mode.

The green VRD ON light illuminates (red light is off) when the VRD is active. Under this condition the open

circuit voltage of the unit is limited to below 10V DC, thus reducing the potential of serious electric shock

(such as when changing electrodes).

The red VRD OFF light illuminates (green light is off) when the VRD is inactive. Under this condition the

output voltage of the unit will be at welding potential which in some cases may exceed 25V DC.