Transarc 170i – Tweco 170i Transarc User Manual

Page 26

TRANSARC 170i

INSTALLATION, OPERATION AND SETUP

3-8

Manual 0-5281

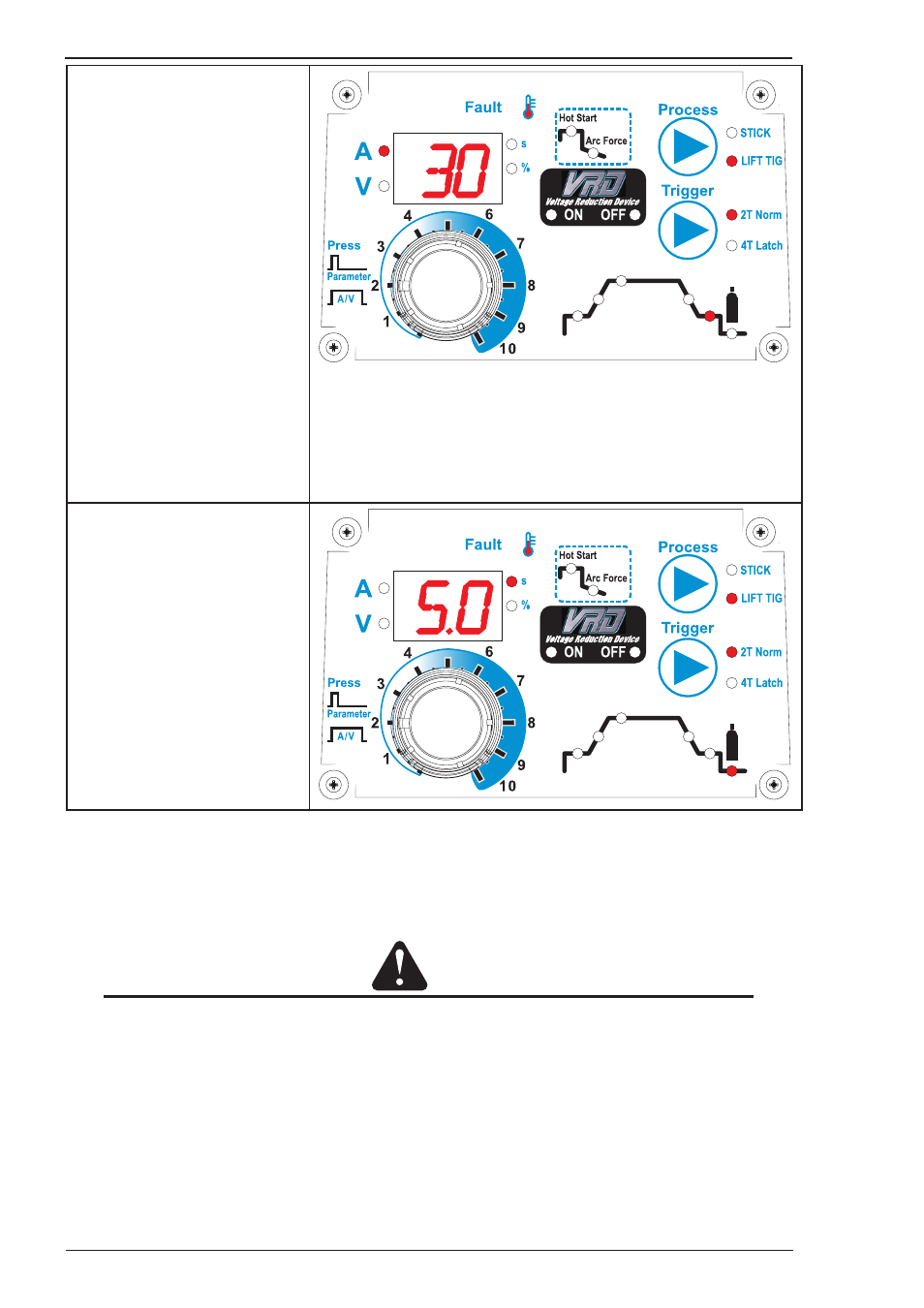

Crater Current

This parameter operates in TIG

mode only.

In 2T mode this is the current at

the end of the down slope current

ramp. When the welding current

reaches the Crater Current value,

the welding current will cease and

the unit will enter Post Flow mode.

In 4T mode, this is the current at

the end of the down slope current

ramp. The welding current will

remain at the Crater Current value

until the torch trigger is released, at

which time the welding current will

cease and the unit will enter Post

Flow mode.

Range is 5 to 170A. Factory default

is 30A.

Post Flow

This parameter operates in TIG

mode only and is used to adjust the

post gas flow time once the arc has

extinguished. This control is used

to dramatically reduce oxidation of

the tungsten electrode.

Range is 0.0 to 30.0 seconds.

Factory default is 5.0 seconds.

5. Positive Welding Output Terminal

The positive welding terminal is used to connect the welding output of the power source to the electrode

holder lead or work lead. Positive welding current flows from the power source via this heavy duty bayonet

type terminal. It is essential, however, that the male plug is inserted and turned securely to achieve a

sound electrical connection.

CAUTION

Loose welding terminal connections can cause overheating and result in the male plug being fused

in the bayonet terminal.

6. Negative Welding Output Terminal

The negative welding terminal is used to connect the welding output of the power source to the TIG

torch or work lead. Negative welding current flows to the power source via this heavy duty bayonet type

terminal. It is essential, however, that the male plug is inserted and turned securely to achieve a sound

electrical connection.