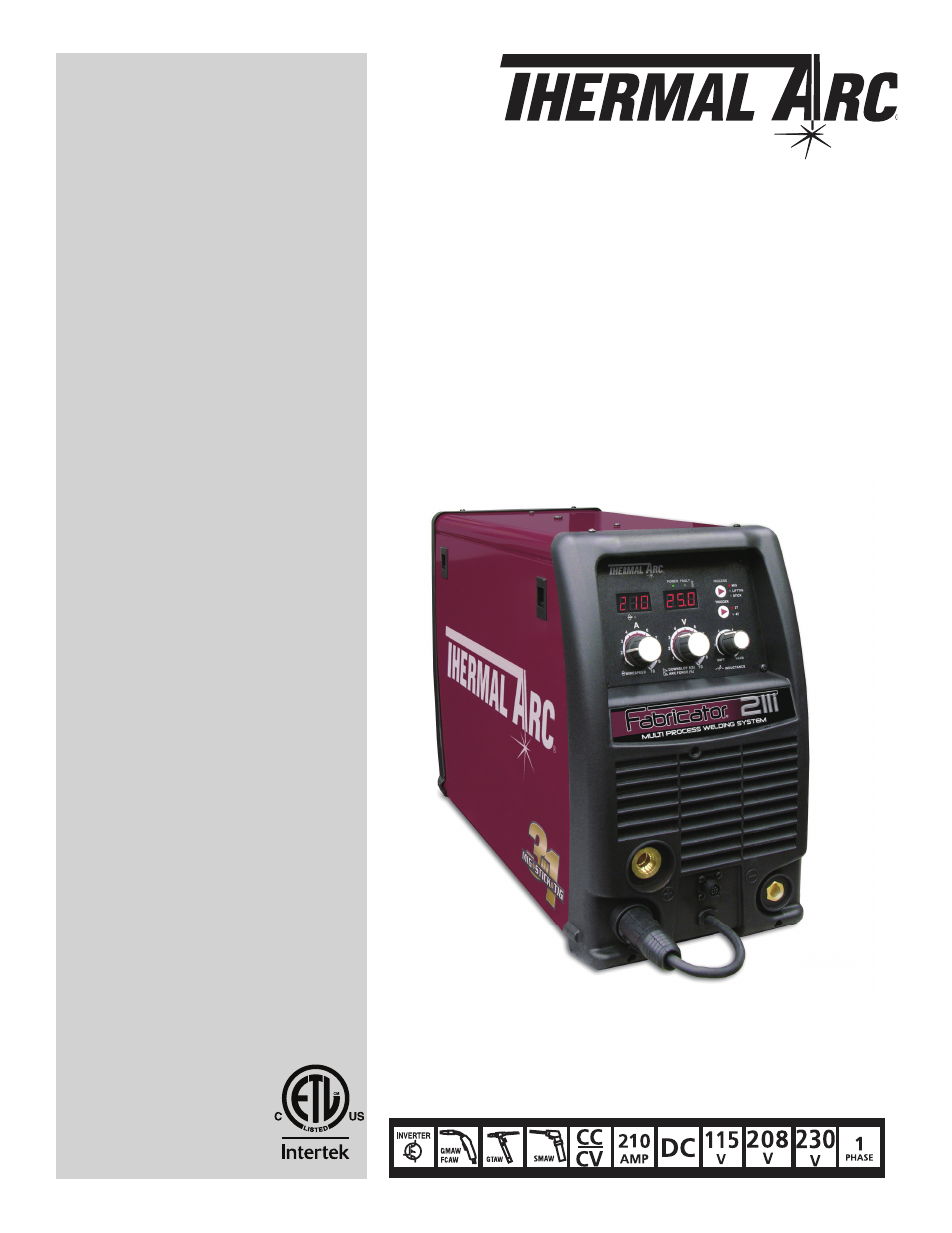

Tweco 211i Thermal Arc Fabricator User Manual

211i operating manual, Fabricator, 3 in 1 multi-process welding system

Table of contents

Document Outline

- 211i FABRICATOR

- SECTION 1: SAFETY INSTRUCTIONS AND WARNINGS

- 1.01 Arc Welding Hazards

- 1.02 General Safety Information For Victor CS Regulator

- 1.03 Principal Safety Standards

- 1.04 Symbol Chart

- 1.05 Precautions De Securite En Soudage A L’arc

- 1.06 Dangers relatifs au soudage à l’arc

- 1.07 Informations Générales de Sécurité

- 1.08 Principales Normes De Securite

- 1.09 Graphique de Symbole

- 1.10 Declaration Of Conformity

- SECTION 2: INTRODUCTION

- SECTION 3: INSTALLATION, OPERATION AND SETUP

- 3.01 Environment

- 3.02 Location

- 3.03 Ventilation

- 3.04 Electricity Supply

- 3.05 Electromagnetic Compatibility

- 3.06 Victor Regulator

- 3.07 Leak Testing The System

- 3.08 When You Finish Using The Regulator

- 3.09 Storage Of The Regulator

- 3.10 Fabricator 211i Power Source Controls, Indicators And Features

- 3.11 Attaching the TWECO Fusion 220A MIG Gun

- 3.12 Installing 33/44 lb Spool (12" diameter)

- 3.13 Installing 12.5 lb Spool ( 8" diameter)

- 3.14 Installing 1 lb Spool (4" diameter)

- 3.15 Inserting Wire Into The Wire Feed Mechanism

- 3.16 Feed Roller Pressure Adjustment

- 3.17 Changing the Feed Roll

- 3.18 Wire Reel Brake

- 3.19 Setup For MIG (GMAW) Welding With Gas Shielded MIG Wire

- 3.20 Setup For MIG (FCAW) Welding With Flux Core (Gasless) Wire

- 3.21 Setup For SPOOL GUN MIG (GMAW) Welding With Gas Shielded MIG Wire

- 3.22 Setup For LIFT TIG (GTAW) Welding

- 3.23 Setup For STICK (SMAW) Welding

- SECTION 4:BASIC WELDING GUIDE

- SECTION 5: POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

- SECTION 6: KEY SPARE PARTS

- APPENDIX 1: FABRICATOR 211i CIRCUIT DIAGRAM