Fabricator 252i installation/setup – Tweco 252i Fabricator User Manual

Page 56

FABRICATOR 252i

INSTALLATION/SETUP

INSTALLATION/SETUP 3-26

Manual 0-5155

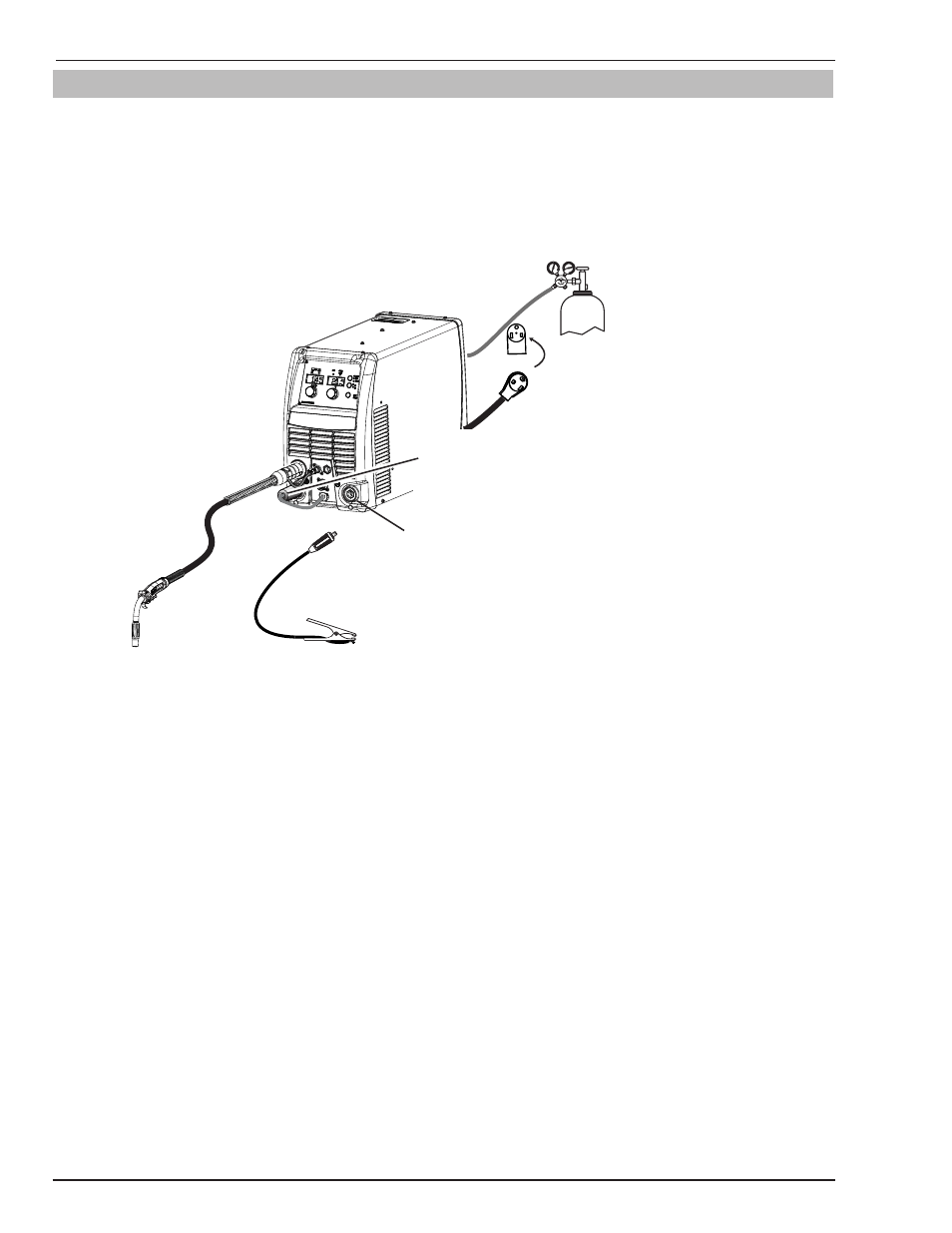

3.18 Set-up MIG (GMAW) Welding with Gas Shielded MIG Wire

The Fabricator 252i is supplied with a Tweco Fusion 250 AMP air-cooled MIG Gun. The Tweco Fusion 250A MIG Gun

is designed with an ergonomic handle and fewer parts to cause performance problems. The Fusion MIG Gun uses

standard readily available Tweco Velocity consumable parts.

When using a non shielded wire, you need to have an external gas source attached to the unit.

For most Non Shielded Wire, connect the Work Lead to the negative - terminal and connect the MIG Gun polarity lead

to the positive + terminal. If in doubt, consult the MIG electrode wire manufacturer.

+

-

Art # A-10550

Connect MIG Gun Polarity

Terminal to +/Positive

(Dinse® type 50)

Negative Output

Terminal

(Dinse® type 50)

Ensure that the gas

cylinder is secured to

a building pillar, wall

bracket or otherwise

securely fixed in an

upright position.

Figure 3-20: MIG Gun Polarity Positive

1. Turn the Main ON/OFF switch OFF (located on the rear panel).

2. Check that the MIG wire size, contact tip, MIG Gun liner and drive roll groove are all the same size before fitting

the MIG wire into the Power Source.

3. Connect the MIG Gun Polarity Lead to the positive welding terminal (+). If in doubt, consult the MIG electrode

wire manufacturer. Welding current flows from the Power Source via heavy duty bayonet type terminals. It is

essential, however, that the male plug is inserted and turned securely to achieve a sound electrical connection.

4. Fit the MIG wire spool and Fusion MIG Gun to the Power Source. (Refer to section 3.08 to 3.12 ).

5. Connect the work lead to the negative welding terminal (-). If in doubt, consult the MIG electrode wire manu-

facturer. Welding current flows from the Power Source via heavy duty bayonet type terminals. It is essential,

however, that the male plug is inserted and turned securely to achieve a sound electrical connection.

6. Fit the welding grade shielding gas regulator/flow gauge to the shielding gas cylinder (refer to Section 3.17)

then connect the shielding gas hose from the rear of the power source to the regulator/flow gauge outlet.

7. Turn the Main ON/OFF switch ON (located on the rear panel).

8. Select MIG mode with the process selection control. (Refer to Section 3.06.3 for further information)

9. Remove the Fusion MIG Gun nozzle and contact tip.

10. Depress MIG Gun trigger to feed the MIG wire out. Then fit the contact tip on the MIG wire and hand tighten

the nozzle in place.

11. Refer to the Weld Guide located on the inside of the wire feed compartment door for further information on

Voltage/Wirespeed settings.