06 system operation, 06 system operation -6 – Tweco CE PAK Master 150XL With Latch Circuit User Manual

Page 32

OPERATION

4-6

Manual 0-2865

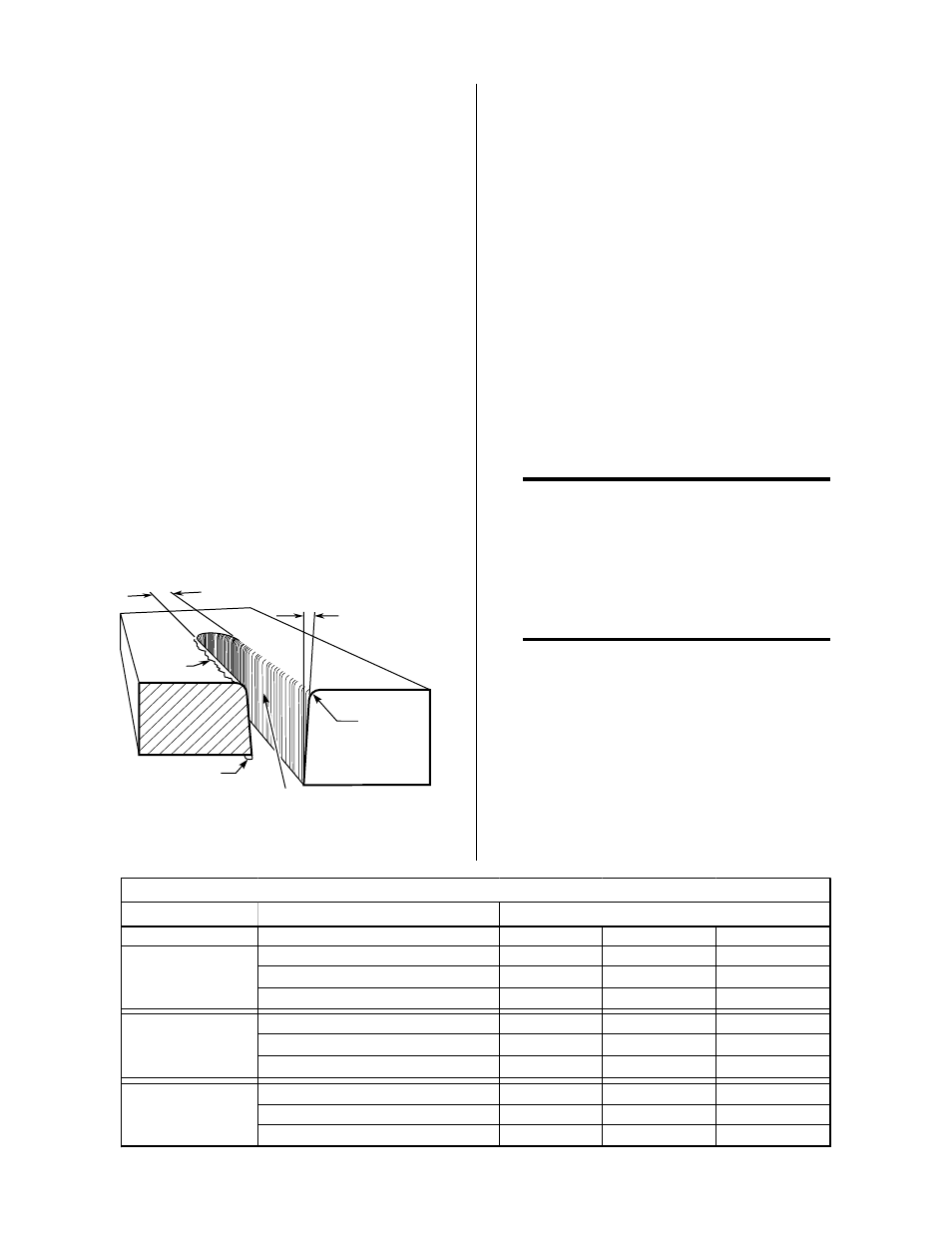

The angle between the surface of the cut edge and a

plane perpendicular to the surface of the plate. A

perfectly perpendicular cut would result in a 0° bevel

angle.

Top-Edge Rounding

Rounding on the top edge of a cut due to wearing

from the initial contact of the plasma arc on the work-

piece.

Dross Build-up and Top Spatter

Dross is molten material which is not blown out of

the cut area and re-solidifies on the plate. Top spat-

ter is dross which accumulates on the top surface of

the workpiece. Excessive dross may require second-

ary clean-up operations after cutting.

Kerf Width

The width of material removed during the cut.

Nitride Build-up

Nitride deposits which may remain on the surface of

the cut when nitrogen is present in the plasma gas

stream. Nitride buildups may create difficulties if

the material is welded after the cutting process.

Kerf Width

Cut Surface

Bevel Angle

Top Edge

Rounding

Cut Surface

Drag Lines

Dross

Build-Up

Top

Spatter

A-00007

Cut Quality on Various Materials

Types of Material

Type of Gases

Material Thickness

Carbon Steel

Stainless

Aluminum

Air Plasma and

Gage (0.5 mm)

Excellent

Good-Excellent Good-Excellent

Air Secondary

Gage to 1 inch (0.5 mm - 25.4 mm)

Excellent

Good

Good

1 to 1-1/2 inch (25.4 mm - 38.1 mm)

Excellent

Good

Good

Nitrogen Plasma

Gage (0.5 mm)

NR

Good-Excellent Good-Excellent

and Air or CO2

Gage to 1/2 inch (0.5 mm - 12.7 mm)

NR

Good-Excellent Good-Excellent

Secondary

1/2 to 1-1/2 inch (12.7 mm - 38.1

)

NR

Good-Excellent Good-Excellent

Ar/H2 Plasma and

Gage to 1/4 inch (0.5 mm - 6.4 mm)

NR

NR

NR

N2 or CO2

1/4 to 1-1/4 inch (6.4 mm - 31.8 mm)

NR

Good

Excellent

Secondary

1/2 to 1-1/2 inch (12.7 mm - 38.1

)

NR

Good

Excellent

Figure 4-6 Cut Quality Characteristics

Cut quality will vary on different types of and material

thicknesses. The table shows the cut quality that can be

expected from this equipment for materials with a thick-

ness from gage to 1-1/2 inches (38.1 mm):

Description of Cut Characteristics

Excellent

- Minimum bevel (0 - 4°), minimum kerf (2 x

tip orifice diameter), little or no dross, smooth

cut surface.

Good

- Slight bevel (0 - 10°), slightly wider kerf (2-1/2 x

tip orifice diameter), some dross (easily re-

moved), medium-smooth cut surface, slight top

edge rounding.

Fair

- Excessive bevel (over 10°), wide kerf (over 2-1/2 x

tip orifice diameter), medium to heavy dross,

rough cut surface, top edge rounding.

NOTES

Cut quality depends heavily on set-up and param-

eters such as torch standoff, alignment with the

workpiece, cutting speed, gas pressures, and op-

erator ability.

4.06 System Operation

NOTE

Frequently review the safety precautions at the front

of this manual.

This section contains operating information which is spe-

cific to the power supply. Detailed operating informa-

tion for torches can be found in the appropriate Torch

Instruction Manual.