Section 4: operation, 01 introduction, 02 functional overview – Tweco PAK 44G User Manual

Page 25: 03 operating control descriptions, Section 4, Operation

Manual 0-2686

19

OPERATION

SECTION 4:

OPERATION

4.01 Introduction

This Section provides a description of the Pak 44G Power

Supply operating controls and procedures. Identification

of the Panel Controls is followed by operating procedures.

4.02 Functional Overview

The main components of the Pak 44G Plasma Gouging

System are and their functions are summarized below.

NOTE

Refer to Appendix V for a System Block Diagram.

A. Torch Connections

• Plasma gas, high frequency, and positive (+) power

for the pilot arc flow to the torch through the black

lead.

• Secondary gas (or water) flows to the torch through

the yellow lead.

• Torch coolant and negative (-) power flow to the

torch through the green water cooled lead.

• Coolant return flows through the red and blue wa-

ter cooled lead.

B. Pilot Arc

When the torch is started an arc is established between

the electrode and gouging tip. The pilot arc makes a

path for transferring the main arc to the work.

C. High Frequency

A high voltage, high frequency current is superim-

posed on the direct current to establish and maintain

the pilot arc.

D. Gouging Arc

The main bridge rectifier converts three-phase AC

power to DC for the pilot and main gouging arcs. The

negative output is connected to the electrode through

the torch lead. The positive output is connected to

the workpiece (via the work cable).

E. Current Control

The desired Gouging current is set on the CURRENT

ADJUST knob. A control circuit stabilized gouging

current against fluctuations due to changes in line

voltages, material thickness, torch standoff and travel

speed. This circuit changes the saturating current in

the reactor and the amount of AC power supplied to

the main bridge rectifier.

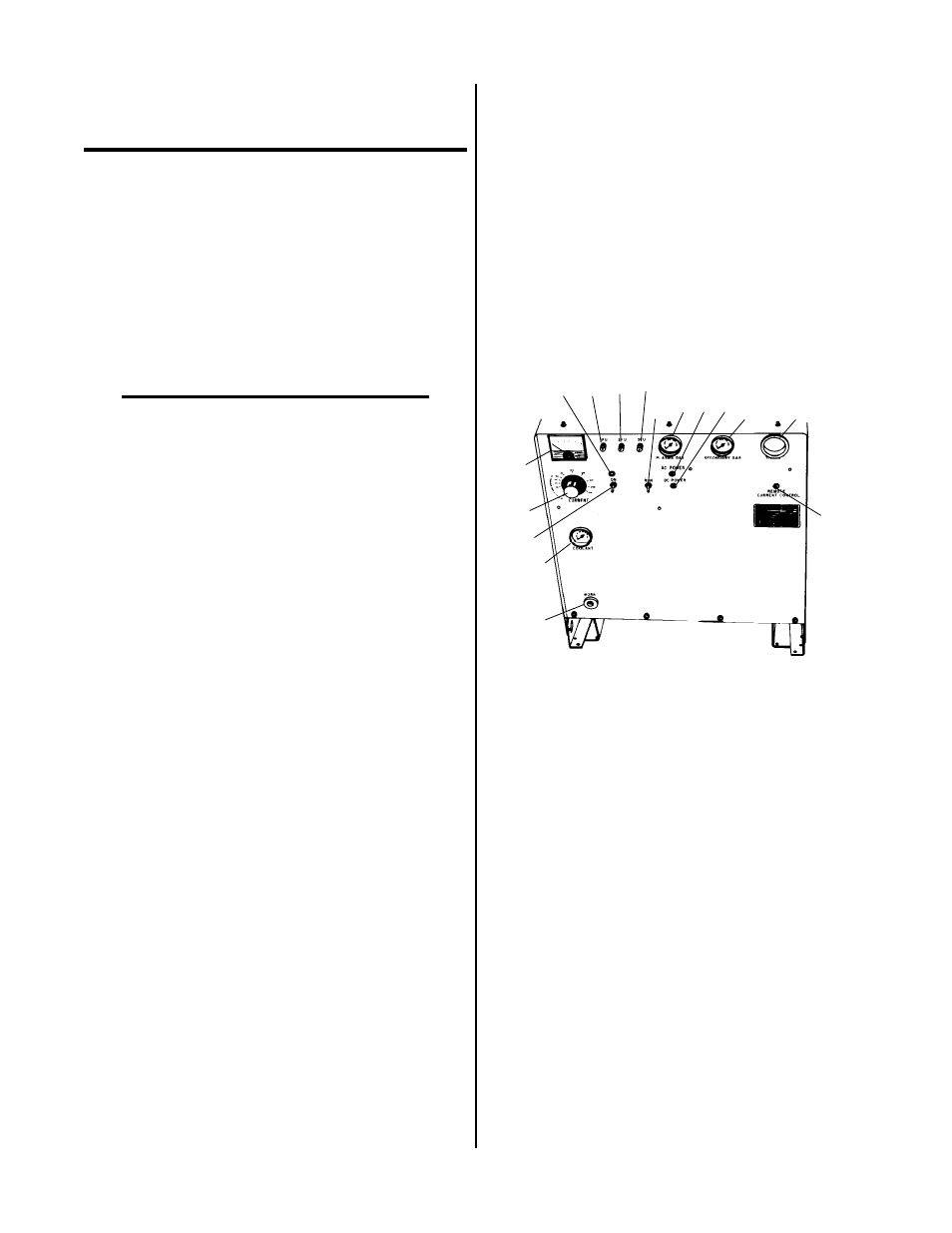

4.03 Operating Control Descriptions

This sub-section provides specific functional descriptions

of the Power Supply operating controls, indicators and

connections. The Power Supply has a Front Panel, Ac-

cess Panel and Rear Panel. Each panel is described in

this sub-section as to the functions of the connections,

switches, and indicators.

A. Front Panel

A-02101

2

1

10

13

12

6

5

16

15

14

9

11

4

8

3

7

Figure 4-1 Front Panel Description

1. Current Adjust Knob

Adjust knob until desired current is indicated on

Ammeter.

2. Ammeter (AM)

Indicates amperage supplied to torch.

3. Ready Indicator (LT3)

Amber light indicates that the ON/OFF switch is

ON, that lead connections access door is closed

and that pump is running.

4. AC POWER Indicator (LT1)

Red light indicates that primary AC power is be-

ing supplied to the system.

5. PLASMA GAS

Indicates pressure at which plasma gas is being

supplied to the torch.