0 maintenance, 1 recommended maintenance schedule, 2 power supply cleaning – Tweco Drag-Gun User Manual

Page 22: 3 torch cleaning

DRAG-GUN Plasma Cutter

18

Operating Manual 0-2682

NOTE

Piloting is harder on parts life than actual cutting

because the pilot arc is directed from the electrode

to the tip rather than to a workpiece. Whenever

possible, avoid excessive pilot arc time to improve

parts life.

2. Torch Standoff

Improper standoff (the distance between the torch tip

and workpiece) can adversely affect tip life as well as

shield cup life. Reducing standoff will generally re-

sult in a more square cut.

NOTE

Although the DRAG-GUN will cut using stand-

off, this unit is primarily a drag-cutting machine.

6.0 MAINTENANCE

6.0 MAINTENANCE

6.0 MAINTENANCE

6.0 MAINTENANCE

6.0 MAINTENANCE

6.1 Recommended Maintenance

6.1 Recommended Maintenance

6.1 Recommended Maintenance

6.1 Recommended Maintenance

6.1 Recommended Maintenance

Schedule

Schedule

Schedule

Schedule

Schedule

WARNING

Disconnect primary power to the system before dis-

assembling the power supply.

NOTE

The actual frequency of maintenance may need to

be adjusted according to usage and the environ-

ment.

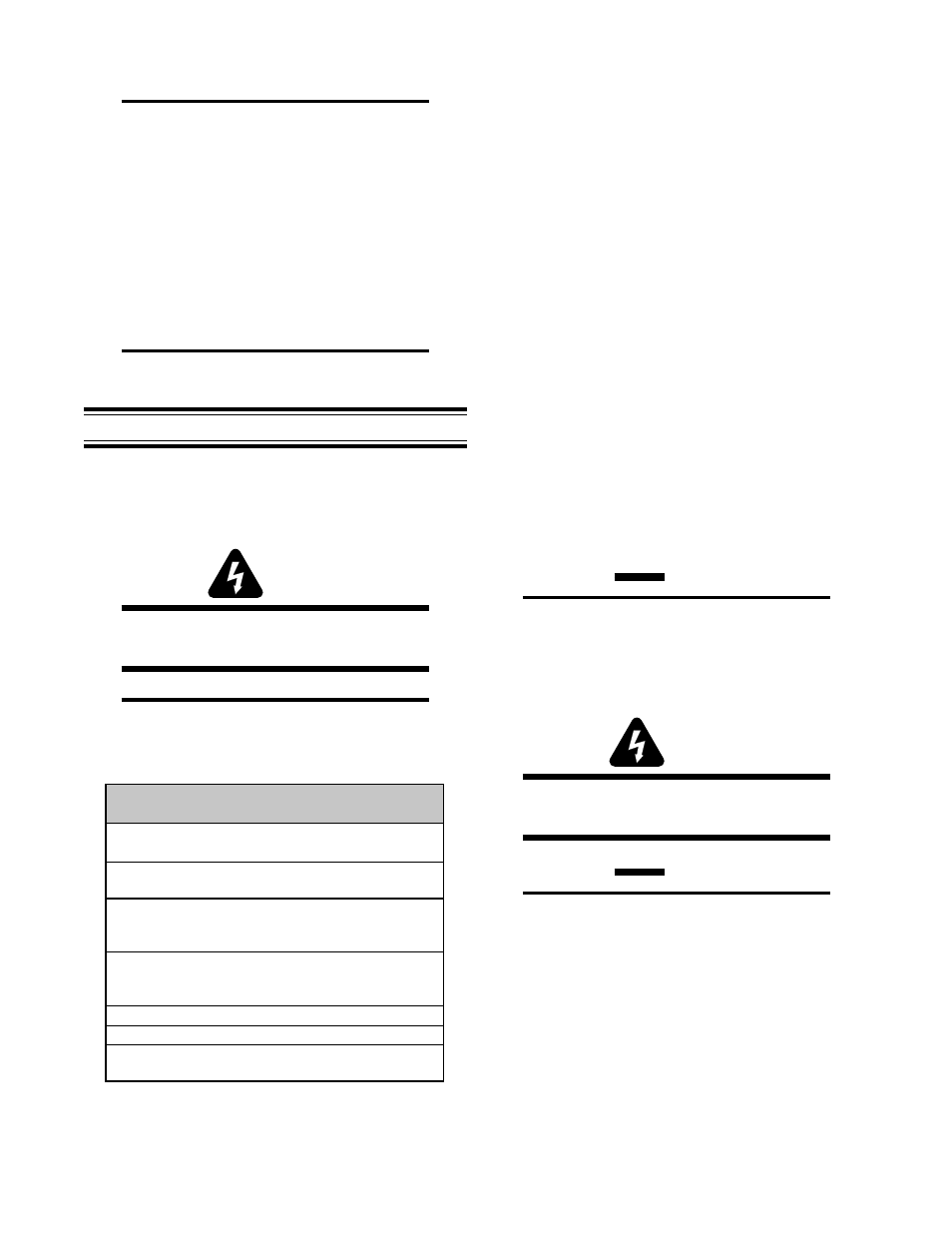

Recommended Routine Maintenance

Schedule

Daily Operational Checks or Every 6

Cutting Hours:

1. Check torch consumables. Replace if

damaged.

2. Inspect torch for any cracks or exposed

wires. Repair or replace before

proceeding.

3. Inspect input power cable for damage or

exposed wires. Repair or replace before

proceeding.

Weekly or Every 30 Cutting Hours:

1. Check for proper fan operation.

2. Blow or vacuum dust and dirt out of the

entire machine, including the air filter.

Figure 6-1 Routine Maintenance

6.2 Power Supply Cleaning

6.2 Power Supply Cleaning

6.2 Power Supply Cleaning

6.2 Power Supply Cleaning

6.2 Power Supply Cleaning

To clean the unit, open the enclosure and use a vacuum

cleaner to remove any accumulated dirt and dust. The

unit should also be wiped clean. If necessary, solvents

that are recommended for cleaning electrical apparatus

may be used. Do not blow air into the power supply dur-

ing cleaning. Make sure to always blow air out of the unit.

Blowing air into the unit can cause metal particles to in-

terfere with sensitive electrical components and cause

damage to the unit.

6.3 Torch Cleaning

6.3 Torch Cleaning

6.3 Torch Cleaning

6.3 Torch Cleaning

6.3 Torch Cleaning

Even if precautions are taken to use only clean air with a

torch, eventually the inside of the torch becomes coated

with residue. This buildup can affect the pilot arc initia-

tion and the overall cut quality of the torch.

The inside of the torch should be cleaned with electrical

contact cleaner using a cotton swab or soft wet rag. In

severe cases, the torch can be removed from the leads

and cleaned more thoroughly by pouring electrical con-

tact cleaner into the torch and blowing it through with

compressed air.

CAUTION

Dry the torch thoroughly before reinstalling.

6.4 Inspection and Replacement

6.4 Inspection and Replacement

6.4 Inspection and Replacement

6.4 Inspection and Replacement

6.4 Inspection and Replacement

of Consumable Torch Parts

of Consumable Torch Parts

of Consumable Torch Parts

of Consumable Torch Parts

of Consumable Torch Parts

WARNING

Disconnect primary power to the system before

disassembling the torch.

CAUTION

Consumable parts may be HOT! Torch parts may

get quite hot during normal operation. Always

wear light cutting gloves when changing torch

parts just after operating the Drag-Gun system.

1. Remove the shield cup from the torch and inspect the

cup for damage. Wipe it clean or replace if damaged.