36cdvt vertical venting, Cdv series direct vent gas fireplace, How to use the vent graph – Vermont Casting 36CDVRRN User Manual

Page 21: Vertical sidewall applications

21

CDV Series Direct Vent Gas Fireplace

20010175

Since it is very important that the vent-

ing system maintain its balance between

the combustion air intake and the flue

gas exhaust, certain limitations as to vent

configurations apply and must be strictly

adhered to.

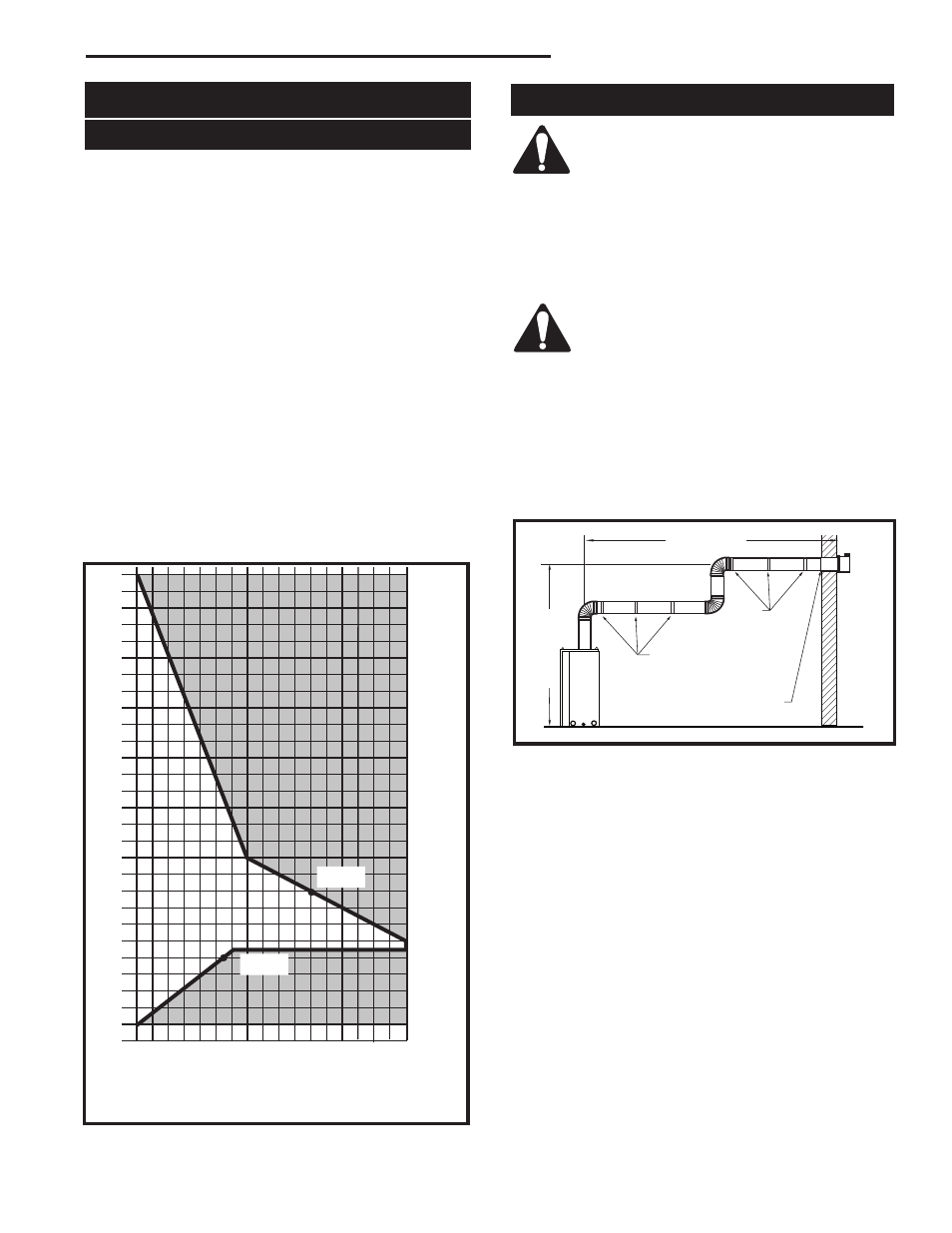

The vent graph showing the relationship between verti-

cal and horizontal side wall venting will help to deter-

mine the various dimensions allowable.

Minimum clearance between vent pipes and

combustible materials is one 1” (25 mm)

on top, bottom and sides unless otherwise

noted.

When the vent termination exits through foundations

less than 20” (508 mm) below siding outcrop, the vent

pipe must flush up with the siding.

It is always best to locate the fireplace in such a way

that minimizes the number of offsets and horizontal

vent length of vent pipe from the flue collar of the fire-

place to the face of the outer wall.

How to Use the Vent Graph

The vent chart should be read in conjunction with the

following vent installation instructions to determine the

relationship of the vertical and horizontal dimensions of

the vent system.

1. Determine the height of the center of the horizontal

vent pipe exiting through the outer wall. Using this

dimension on the Sidewall Vent Graph (Fig. 39),

locate the point intersecting with the slanted graph

line.

2. From the point of this intersection, draw a vertical

line to the bottom of the graph.

3. Select the indicated dimension, and position the

fireplace in accordance with same.

Example A:

If the vertical dimension from the floor of the fireplace

is 11’ (3.4 m) the horizontal run to the face of the outer

wall must not exceed 14’ (4.3 m).

Example B:

If the vertical dimension from the floor of the unit is 7’

(2.14 m), the horizontal run to the face of the outer wall

must not exceed 8¹⁄₂’ (2.6 m).

36CDVT Vertical Venting

Horizontal dimension from the outside face of the

wall to the center of the fireplace vent flange

Sidewall vent graph showing the relationship between vertical

and horizontal dimensions for a Direct Vent flue system.

V

ertical dimension from the fl

oor of the unit

to the center of the horizontal vent pipe

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

eg: A

eg: B

CFM102

DV Graphic

9/28/00 sta

Fig. 39 Sidewall venting graph. (Dimensions in feet)

Vertical Sidewall Applications

FP1012

Top vent max run

1/25/00 djt

20' (6m)

7.5' (2.3m)

Pipe Straps

Every 3’ (914mm)

Firestop/Zero

Clearance Sleeve

Pipe

Straps Every

3’ (914mm)

FP1012

Fig. 40 Support straps for horizontal runs.

Horizontal plane means no vertical rise exists on this

portion of the vent assembly.

•

The maximum number of 90° elbows per side wall

installations is three (3).

•

If a 90° elbow is fitted directly onto the fireplace

flange the maximum horizontal vent run before the

termination or a vertical rise is 36” (914 mm).

•

If a 90° elbow is used in the horizontal vent run

(level height maintained) the maximum horizontal

vent length is reduced by 36” (914 mm). This does

not apply if the 90° elbows are used to increase or

redirect a vertical rise.

Example: According to the chart the maximum

horizontal vent length in a system with a 7.5’ (2.3 m)

vertical rise is 20’ (6 m) and if a 90° is required in

the horizontal vent it must be reduced to 17’ (5.2 m).

In Figure 42, Dimension A plus B must not be

greater than 17’ (5.2 m).