Before use – Triton TA 235CSL User Manual

Page 8

7

GB

BEFORE USE

Before Use

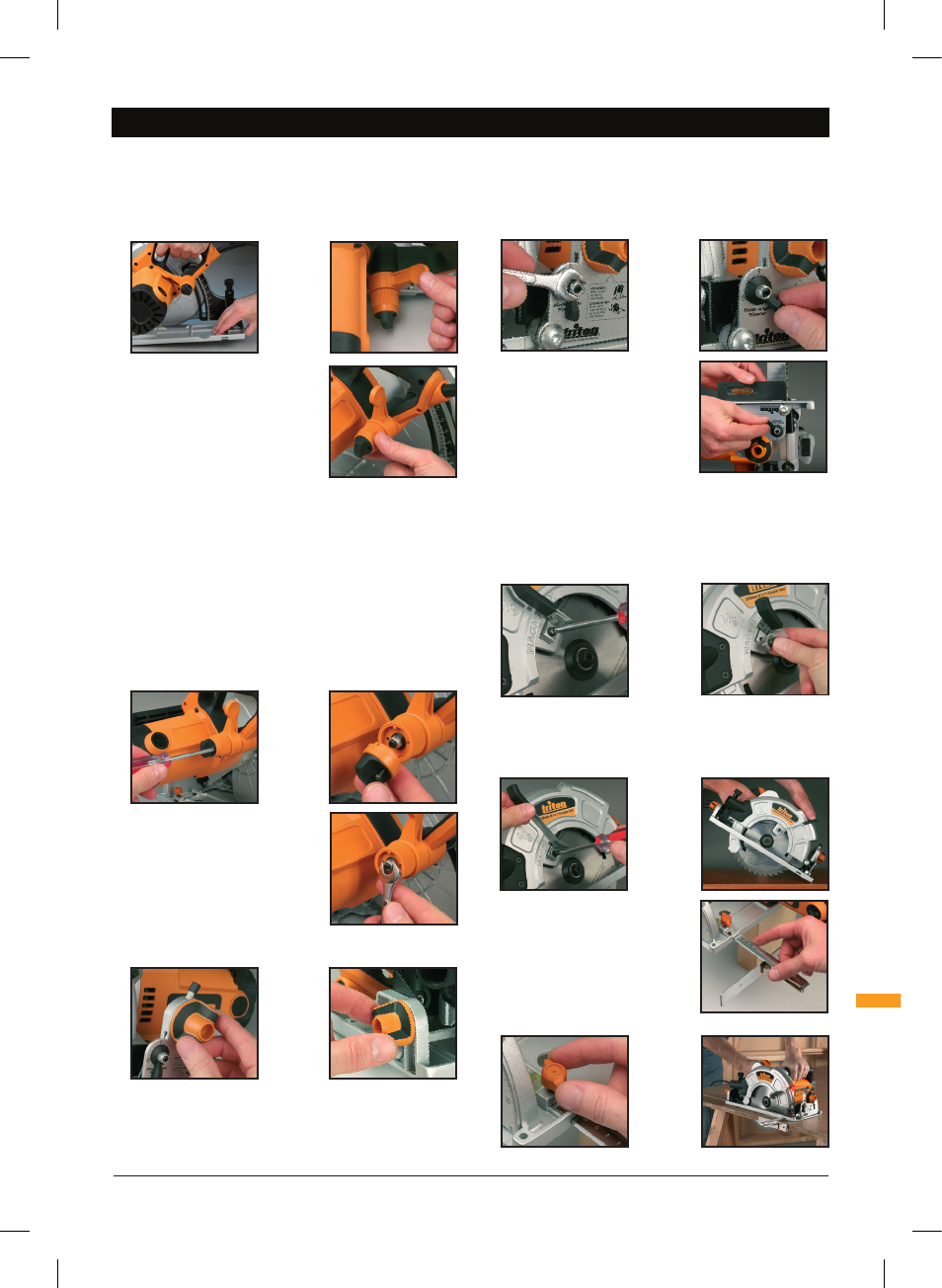

ADJUSTING THE CUTTING DEPTH

Ensure that the tool is switched off and disconnected from the power supply before

making any adjustments or installing or removing blades.

1. Loosen the Depth Adjustment Locking Lever (24) and lift the back of the saw

away from the baseplate until the approximate depth is achieved. Push down on

the lever to lock the saw in position.

2. For fine depth adjustments, lock the saw at the

approximate depth and then turn the micro depth

adjustment knob for the exact depth. Turn the

micro depth adjustment knob in a clockwise

direction to decrease the depth of cut, turn in an

anti-clockwise direction to increase the depth of

cut. The adjustment range is 6mm, if insufficient,

reset the main depth adjustment, and fine tune

again. The micro-adjustment knob must be set

to full depth to achieve the 82mm maximum

depth of cut.

3. The circular saw also features a rack & pinion depth adjustment feature. The

rack & pinion depth adjustment is most useful when the saw is mounted below a

Triton Workcentre.

4. To adjust the depth using the rack & pinion feature loosen the Depth Adjustment

Locking Lever (24) and then turn the Rack & Pinion Adjustment Knob (23) to

adjust the cutting height. Turn the knob in an anti-clockwise direction to increase

the cutting depth, turn in a clockwise direction to decrease the cutting depth.

Tighten the depth adjustment locking lever to lock the saw in position.

ADJUSTING THE DEPTH LOCKING LEVER TENSION

If the Depth Adjustment Locking Lever (24) is not providing enough tension adjust

as follows:

1. Loosen and remove the 2 Phillips head screws that secure the Rack & Pinion

Adjustment Knob (23). Remove the adjustment knob, this will reveal the locking

lever tension nut.

2. Using a 10mm wrench tighten the tension nut

in a clockwise direction to increase the tension

of the Depth Adjustment Locking Lever (24).

3. Once the locking lever is providing sufficient

tension replace the adjustment knob and secure

using the 2 Phillips head screws.

4. Check the operation of the locking lever before

operating the saw.

ADJUSTING THE BEVEL ANGLE

1. Bevel angles can be set anywhere within the range 0° to 47°. Pre-set stops are

available at 0°, 15°, 22.5°, 30° and 45° for quick, accurate bevel settings.

2. Loosen the Front and Rear Bevel Lock Knobs (13 and 4) and depress the Bevel

Detent Latch (12). Pivot the saw to the angle you require then release the detent

latch. A small movement of the saw motor will allow the latch to pop up into the

detent position. Tighten both bevel lock knobs.

3. For selecting other angles, leave the detent latch disengaged by pushing it down

and back towards the motor, where it has a ‘lock-out’ position. Firmly tighten

both knobs at the required angle.

FINE-TUNING BEVEL ANGLE & STOPS

1. You can fine-tune the calibration scale and the bevel detent positions by +/-2˚.

2. Make sure the saw is set at 0˚ and the bevel detent latch is engaged.

3. Loosen the rear Bevel Lock Knob (4), also

loosen the Nyloc nut on the Bevel Micro

Adjustment Lever (15) using a 10mm spanner.

4. Adjust the trimmer to the left or right until the

blade is square to the baseplate or to the Triton

table.

5. Tighten the rear bevel lock knob and Nyloc nut

after any adjustments.

Note: For full trim range adjustment ensure the blade

depth is set 2–3mm below maximum, for motor clearance. Full depth can be re-set

once the adjustment has been made.

BLADE GUARD LEVER

For plunge or pocket cuts, use the Long Blade Guard Lever (21). To change the lever

follow the below instructions:

1. Loosen and remove the Phillips head screw holding the Short Blade Guard Lever

(5). Also remove the blade guard lever.

2. Fit the Long Blade Guard Lever (21) into the same position.

3. Replace the Phillips head screw and tighten to secure the long blade guard lever

in position.

4. The long blade guard lever can now be used to provide better control of the lower

guard when performing pocket cuts.

RIP FENCE ADJUSTMENT

1. The Rip Fence (17) can be used on the left

or the right of the blade. Using the rip fence

provides accurate cuts without the need to work

free-hand following pencil lines.

2. Locate the rip fence into the mounting slots

at the front of the Base Plate (6) and tighten

the Locking Knob (18) to lock it at the required

cut width. For greater width setting, the thumb

screw can be repositioned to the inner or outer clamp location.

TA235CSL_Z5MANPRO1_V2.indd 7

06/11/2013 12:23