Rite-Ride 2518 User Manual

Page 7

use a PVC cutter, side cuts, scissors, or anything that will

crush or squeeze the line while cutting. When installing

the tubing into a fitting, push the tubing into the fitting

until it bottoms out. Avoid sharp bends in the tubing as

they may buckle over time.

From the compressor, cut a length of tubing about

3-4 inches long. Attach one end to the compressor tee

fitting and the other to a tee fitting. Route one branch

to the tank and the other to the valve block inlet.

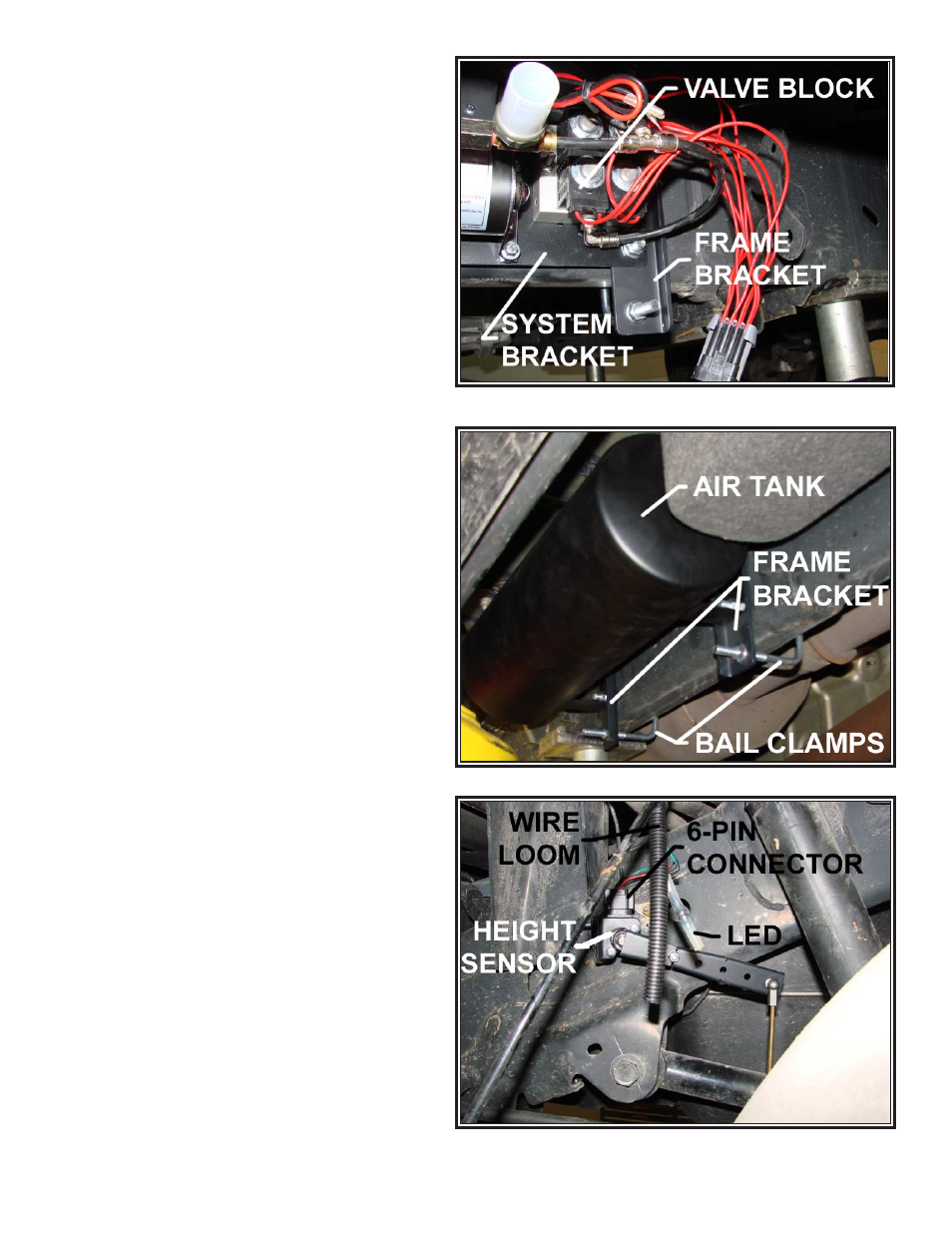

See

Figure “O”.

Route tubing that runs from the valve block to each

air spring, individually. Attach the tubing to the air spring.

Cut the line between the valve block and each air spring

and install a tee fitting. Use the open branch of the tee

to run airline to a location where an inflation valve can

be mounted, protected and accessed easily with an air

chuck. The rear bumper near the license plate provides

a good location for a secure mounting location. Drill a

5/16" hole to accept the inflation valve if needed. Attach

the inflation valve and complete the air line connection.

See Figure “O”.

STEP 10: PLACING THE VEHICLE BACK ON

THE GROUND

Using the manual inflation valves, slowly inflate the air

springs to 15-20 psi. Ensure the sleeves are rolling over

the pistons and are not bound or twisted.

See Figure

“P”, “Q”, & “R”.

Reinstall the wheels but leave the fender liner off.

Slowly lower the vehicle to the ground, checking fre-

quently to make sure the sleeves continue to roll over

the pistons.

See Figure “P”, “Q”, & “R”.

Once the vehicle is on the ground, increase the

pressure in the air springs so that the measurement from

the lip of the wheel to the lip of the fender is exactly the

same as the recorded measurement from the beginning

of this installation.

NOTE: THE AIR SPRINGS MAY HAVE

DIFFERENT PRESSURES AT THE CORRECT RIDE

HEIGHT. See Figure “A”.

STEP 11: SETTING RIDE HEIGHT

Find a fuse that is active at +12VDC when the ignition is

on (M49 position). Insert the fuse tap into the fuse box

and secure.

Attach the red wire with the in-line fuse from the

harness to the positive terminal of the battery. Attach

the black wire from the harness to the negative terminal

of the battery.

Turn the ignition to the vehicle ‘on’ position. The

compressor will start running to fill the air tank to 120

psi. Once complete, the height sensor linkages can be

installed.

See Figure “S”.

Hand tighten one sensor linkage to each end of the

two M5 threaded rods. The openings should be facing

in opposite directions after being tightened. Using pliers,

carefully snap the socket of the sensor linkage onto the

ball of the height sensors brackets. It is very important

that the height sensor arm is parallel with the ground and

the LED is illuminated. If the LED is not illuminated, adjust

the length of the threaded rod until the LED is glowing.

Reinstall the fender liners.

Finally, plug the 8-pin connector from the wire har-

ness into the valve block. See

Figure “T”.

Figure “J”

Figure “K”

Figure “L”