Rite-Ride 2518 User Manual

Page 5

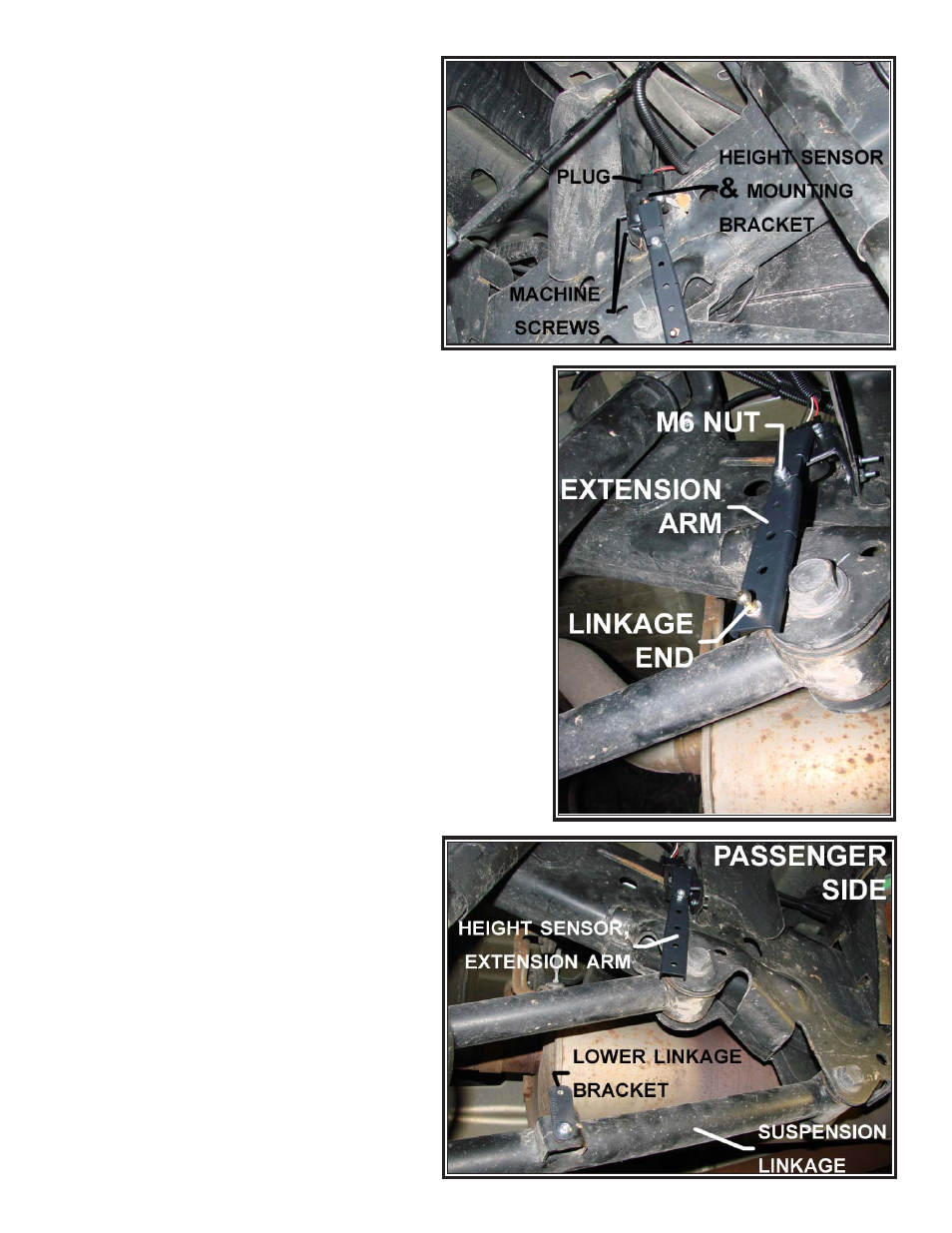

be parallel with the ground. The bracket will angle the

height sensor arm inboard to allow the arm to swing

freely throughout the suspension travel. Ensure the

extension arm does not interfere with the shock.

FOR CREW CAB: The height sensor brackets should

be installed just behind the bed mount brackets

approximately halfway up the frame. This should be

above the front vehicle suspension mount.

FOR QUAD CAB/REGULAR CAB: The height sensor

brackets should be installed above the front vehicle

suspension mount, approximately halfway up the

frame. This is about 10 inches back from the bed

mount bracket.

While holding the height sensor bracket in place, use

(2) 10-16 x 3/4 self tapping screws to attach the height

sensor bracket to the vehicle on each side. NOTE: 7/32"

holes and machine screws (not provided) can be used

in place of the self tapping screws.

Attach the height sensor to the installed bracket using (2) M5-0.8

X 8mm machine screws on each side.

See Figure “D”.

STEP 5: INSTALL THE AIR SPRINGS

The bottom of the air spring assembly has a threaded hole that must

face the rear of the vehicle and the air fitting on the top should face

the front of the vehicle. Place the air spring assembly on the lower

axle mount. Using the 1/4"-20 x 3/4" button head screws provided,

secure the bottom of the air spring assembly to the lower mount.

See

Figure “H”.

Place the top plate on the top side of the upper mount. Unroll the

air spring, by pushing the top of the air spring up, until the air spring

assembly reaches the upper mount on the vehicle. Place the top plate

above the vehicle’s upper spring seat by aligning the top plate to accept

the threaded studs from the air spring assembly. Hand tighten the 3/8"-

16 nuts (serrated face) to the top plate.

DO NOT ALLOW THE AIR

SPRING SLEEVE TO TWIST. Once the air fitting is correctly aligned

towards the front of the vehicle and you have ensured the sleeve is not

twisted, tighten the 3/8"-16 nuts

See Figure “H”.

Reinstall the shocks on both sides of the vehicle.

STEP 6: PREASSEMBLE THE COMPRESSOR, VALVE

BLOCK, AND ECU MOUNT

See Figure “U” for bracket layout. The mounting plate for the com-

pressor, valve block, and ECU has predrilled holes to accept each

component.

All components that are mounted to

the plate should have the head of the bolts on the

back side of the plate for clearance.

The compressor mounts in the lower left side with

the intake pointing left. Use four 10-32 X 1" machine

screws with washers and nylock nuts to mount to the

plate. Attach the compressor tee fitting to the check

valve on the output side of the compressor. Attach the

pressure switch to the compressor tee.

See Figure

“I”. The ECU mounts directly above the compressor

with two, 4-40 X 5/8” machine screws and nylock nuts.

See Figure “I”.

Before mounting the block, install the 1/8 NPT

straight air fittings into the ports labeled ‘LR’ and ‘RR’.

Tighten to engage the orange thread sealant. Install

the 1/8 NPT elbow into the port marked ‘IN’. Hand-

tighten, then turn an additional 1/2 turn with a wrench.

The valve block should be oriented so that the exhaust

port points to the right and the inlet is down. Use the

1/4"-20 X 1-3/4" bolts with washers and nylock nuts

to secure the block in place.

See Figure “J”.

Figure “D”

Figure “E”

Figure “F”