Wing and stabilizer installation – E-flite F-16 400 DF ARF w/Motor & Fan Unit User Manual

Page 4

4

E-flite F-16 ARF Assembly Manual

Wing and Stabilizer Installation

Required Parts

Fuselage

Wing panel (right and left)

Stabilizer (right and left)

2mm x 12mm self-tapping screw (4)

Required Tools and Adhesives

6-minute epoxy

Mixing cup

Mixing stick

Epoxy brush

Paper towel

Rubbing alcohol

Sandpaper

Phillips screwdriver: #1

During the manufacturing process it is possible that a

slight amount of glue may seep in to the inner side of

the wing joiner socket. If you are having trouble with

the wing fitting flush against the fuselage check the

inside of the joiner socket. If some glue has seeped

into the socket use a small hand file to remove it.

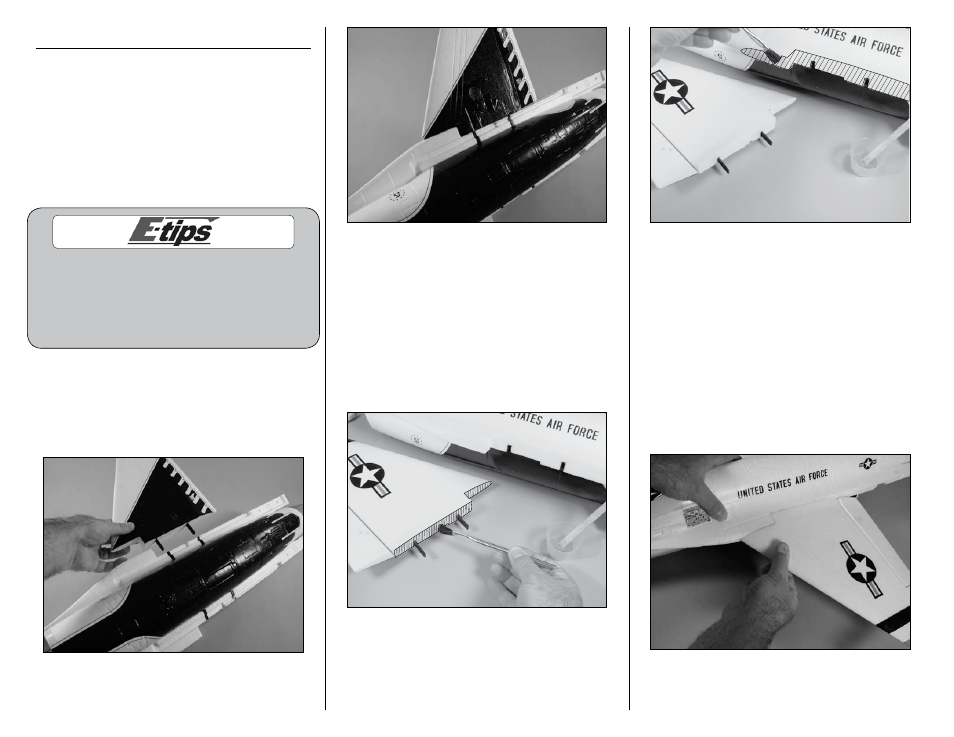

1. Test fit the wing panel to the fuselage by sliding

the joiners into the joiner sockets of the fuselage.

The panel must fit tightly against fuselage when

installed. If it does not, you may be required to

sand the end of the joiner slightly so the wing will

have a flush fit against the fuselage.

Important: You will be required to quickly

perform the next few steps before the epoxy

begins to cure. Read through the following

steps to prepare yourself for the gluing process.

2. After checking the fit, remove the wing panel

from the fuselage. Prepare 1/4-ounce (10cc) of

6-minute epoxy and brush a very light coating of

epoxy on the wing and fuselage where they

contact each other. Also brush some glue into the

inside of the joiner socket.

Note: You can use a paper towel that has had

rubbing alcohol applied to it to remove any

excess epoxy from your airframe. Use care

not to get the alcohol on the decals as it could

damage them.

3. Slide the wing panel back into position on

the fuselage, pressing the wing tightly against

the fuselage. It is best to hold the wing panel in

position until the epoxy cures, as tape will

damage the decal if it is applied directly to the

decal. Be sure to check the alignment of the wing

while the glue is drying. Use the picture in the

next step for reference.