Speed control and receiver installation – E-flite F-16 400 DF ARF w/Motor & Fan Unit User Manual

Page 13

13

E-flite F-16 ARF Assembly Manual

18. The nose gear will slide into the hole in the

steering arm as its final destination. The screw

at the steering arm will then be tightened so it is

resting in the flat area as indicated back in Step

14. Use a #1 Phillips screwdriver to tighten the

screw in the steering arm. Always remember to use

threadlock on metal-to-metal fasteners to prevent

them from vibrating loose.

Note: The steering arm and wheel will be

parallel to each other as illustrated below.

19. Position the gear so there is a gap of

1/32-inch (.5mm) between the steering arm and

the servo horn so they do not bind during the

operation of the nose gear. With the wheel collar

resting lightly against the fuselage as shown, use

a #1 Phillips screwdriver to tighten the screw in

the wheel collar. The screw at the wheel collar

will be tightened so it is resting in the flat area

as indicated back in Step 14. Always remember

to use threadlock on metal-to-metal fasteners to

prevent them from vibrating loose.

You can place a piece of paper between the

steering arm and servo arm to achieve the correct

amount of gap before securing the wheel collar.

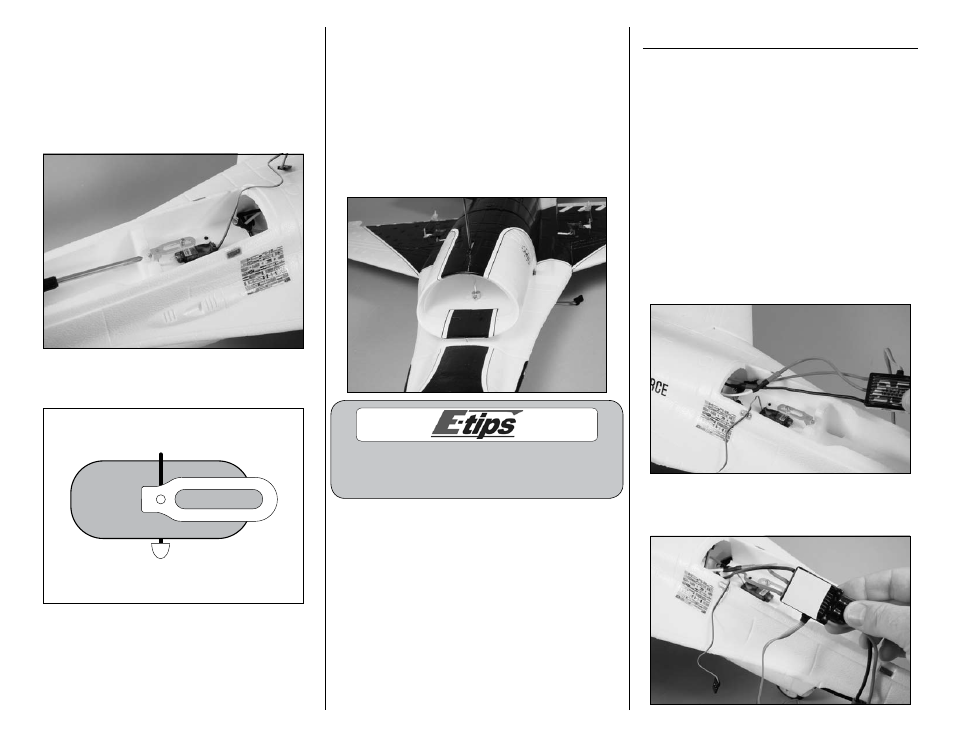

Speed Control and Receiver Installation

Required Parts

Speed control

Assembled airframe

Receiver

Hook and loop tape

Note: Due to the current draw of the system

and the location of the electronics. We

recommend that throttle management is used

during each flight. Using full power throughout

the duration of the flight will result in shorter

flight times and could result in a shorter life

span for the electronics and batteries.

1. Plug the wires from the speed control and motor

together. The wires from the motor will be just long

enough that they can be accessed from the cockpit

area of your model.

2. Apply a small piece of hook and loop tape to

the bottom of the speed control.