Iv. replacement parts list, V. membrane replacement, Vi. appendix – Watts PWR2511 User Manual

Page 7: Temperature correction factors

7

item NumbeR

DescRiPtioN

1

Pre filter housing 10"

2

RO membrane pressure vessel 2

1

⁄

2

" x 14" SS

3

RO membrane pressure vessel 2

1

⁄

2

" x 21" SS

4

RO membrane pressure vessel 2

1

⁄

2

" x 40" SS

5

Pressure gauge, 2", 0-100psi, dry, bottom mount

6

Pressure gauge, 2", 0-100psi, dry, back mount

7

Pressure gauge, 2

1

⁄

2

", 0-400psi, LF

8

Flow meter 0.1 – 1.0 gpm

9

Flow meter 0.2 – 2.0 gpm

10

Product pressure switch

11

Product pressure switch with auto / off lever

12

Motor 0.5 HP single phase 120 volt

13

Pump 140 GPH carbonator with relief valve

14

Low-pressure controller

15

Low-pressure switch, ¼" MPT, 3 – 40psi

16

Reject & recycle brass needle valve

17

Inlet solenoid valve,

1

⁄

2

", 120 volt coil

18

2

1

⁄

2

" x 14" RO membrane

19

2

1

⁄

2

" x 21" RO membrane

20

2

1

⁄

2

" x 40" RO membrane

21

Prefilter cartridge, 10", 5 micron

22

Product check valve, SS

IV. Replacement Parts List

A list of common replacement parts is provided below. Contact your

dealer for replacement parts assistance.

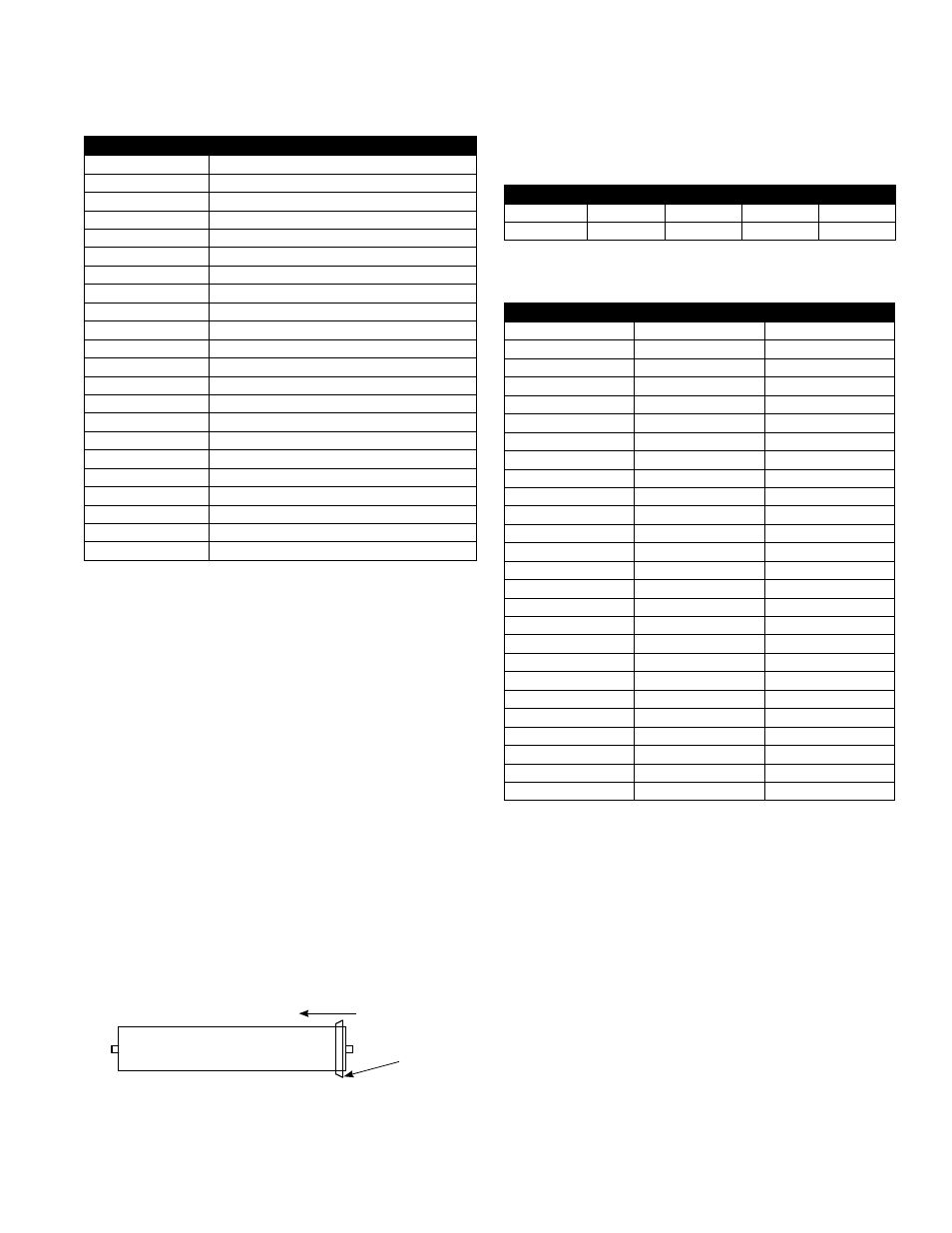

V. Membrane Replacement

1. Turn off the system and close the feed water shutoff valve.

2. Disconnect the tubing from the pressure vessel.

3. Remove the retaining "U" pins from the pressure vessels.

4. Push the old membrane out of the vessel in the direction of the

feed flow

5. Record the serial numbers of the new membranes.

6. Lightly lubricate the brine seals on the new membranes with

clean water.

7. Install the new membranes in the direction of flow with the brine

seal end going in last.

8. Lightly lubricate the end cap internal and external O-rings with

glycerin.

9. Install the end caps and secure them with the "U" pins.

10. Reconnect the tubing to the pressure vessel.

11. Verify that all retaining "U" pins are installed.

12. Follow the start up procedure in section III-D.

Brine

Seal

Flow Direction

Membrane

°c

°F

coRRectioN FactoR

30

86

1.16

29

84.2

1.13

28

82.4

1.09

27

80.6

1.06

26

78.8

1.03

25

77

1.00

24

75.2

0.97

23

73.4

0.94

22

71.6

0.92

21

69.8

0.89

20

68

0.86

19

66.2

0.84

18

64.4

0.81

17

62.6

0.79

16

60.8

0.77

15

59

0.74

14

57.2

0.72

13

55.4

0.70

12

53.6

0.68

11

51.8

0.66

10

50

0.64

9

48.2

0.62

8

46.4

0.61

7

44.6

0.59

6

42.8

0.57

5

41

0.55

Multiply the nominal product flow at 25° C by the temperature correction factor to

determine the flow at various other temperatures.

VI. Appendix

The following tables are intended as a guide to determining the flow

rates for the PWR2511 series RO systems. All flows are in gallons

per minute (GPM).

Nominal flows for systems operating at 50% recovery.

Model nuMber

PWR25111011

PWR25112011

PWR25113011

PWR25113021

Product

0.10

0.17

0.41

0.83

reject

0.10

0.17

0.41

0.83

Temperature Correction Factors