Ro system troubleshooting – Watts PWR2511 User Manual

Page 6

6

G. Troubleshooting

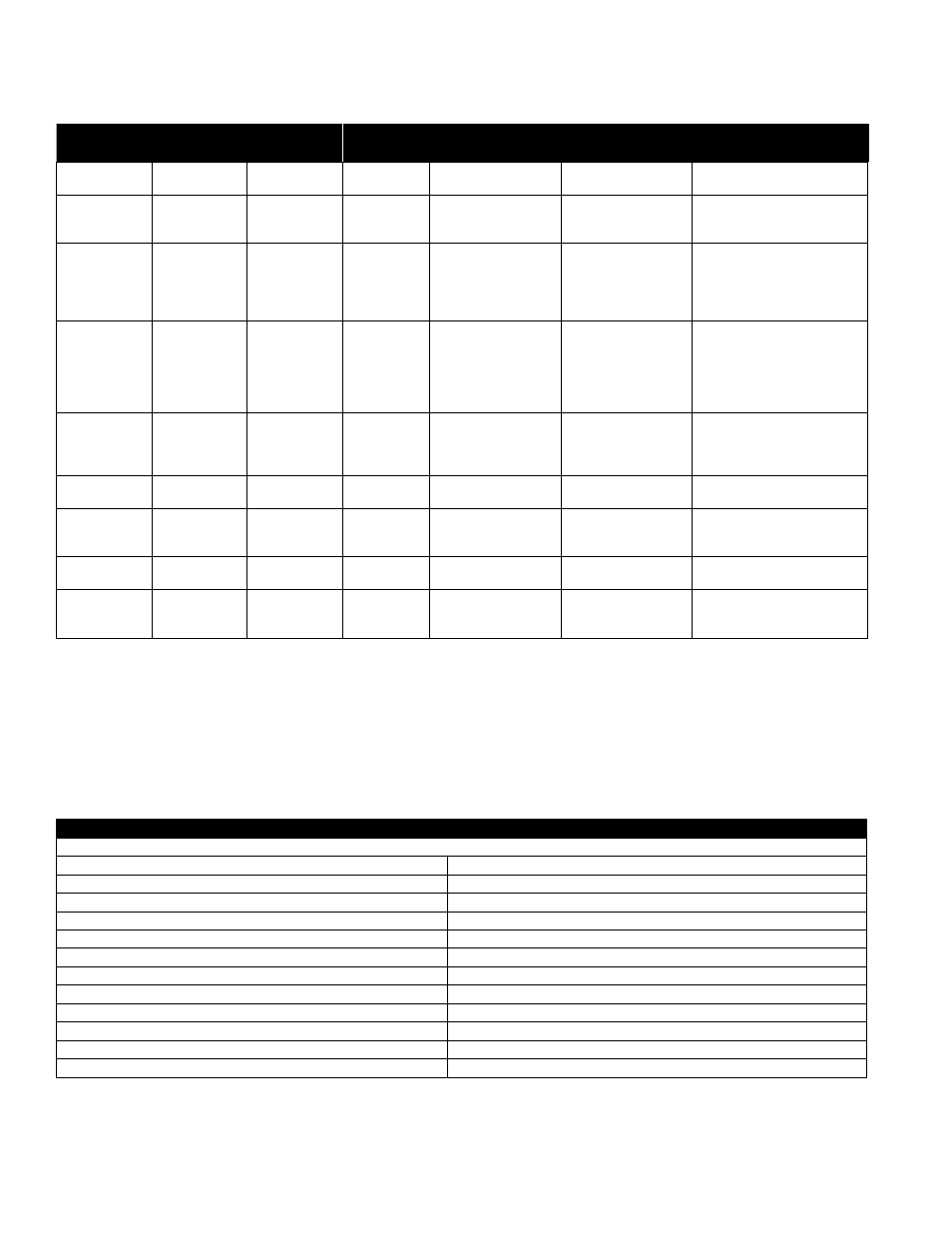

RO Membrane Troubleshooting Guide

sYmPtoms

salt PassaGe

PeRmeate FloW

PRessuRe DRoP

locatioN

Possible causes

veRiFicatioN

coRRective actioN

Normal to increased Decreased

Normal to increased Predominantly

first stage

Metal oxide

Analysis of metal ions in

cleaning solution.

Improved pretreatment to remove met-

als. Cleaning with acid cleaners.

Normal to increased Decreased

Normal to increased Predominantly

first stage

Colloidal fouling

SDI measurement of feed/

X-ray diffraction analysis of

cleaning sol. residue.

Optimize pretreatment system for

colloid removal. Clean with high pH,

anionic detergent formulation.

Increased

Decreased

Increased

Predominantly

last stage

Scaling (CaSO

4

, CaSO

3

,

BaSO

4

, SiO

2

)

Analysis of metal ions in

cleaning sol. Check LSI of

reject. Calculate maximum

solubility for CaSO

4

, BaSO

4

,

SiO

2

in reject analysis.

Increase acid addition and scale

inhibitor for CaSO

3

and CaSO

4

. Reduce

recovery. Clean with an acid formula-

tion for CaCO

3

, CaSO

4

and BaSO

4

.

Normal to moderate

increase

Decreased

Normal to moderate

increase

Can occur in any

stage

Biological fouling

Bacteria count in permeate

and reject. Slime in pipes

and vessels.

Shock dosage of sodium bisulfite.

Continuous feed of low conc. bisulfite

at reduced pH. Peracetic acid steriliza-

tion. Clean with alkaline anionic sur-

factant. Chlorine dosage upstream with

dechlorination. Replace cartridge filters.

Decreased or mod-

erately increased

Decreased

Normal

All stages

Organic fouling

Destructive testing, e.g. IR

reflection analysis.

Optimization of pretreatment system

(e.g. coagulation process.) Resin/

activated carbon treatment. Clean with

high pH detergent.

Increased

Increased

Decreased

Most severe in

the first stage

Chlorine oxidant attack

Chlorine analysis of feed.

Destructive element test.

Check chlorine feed equipment and

dechlorination equipment.

Increased

Increased

Decreased

Most severe in

the first stage

Abrasion of membrane by

crystalline material

Microscopic solids analysis

of feed. Destructive ele-

ment test.

Improved pretreatment. Check all filters

for media leakage.

Increased

Normal to increased Decreased

At random

O-ring leaks, End or side

seal glue leaks.

Probe test. Vacuum test.

Colloidal material passage.

Replace O-rings. Repair or replace

elements.

Increased

Normal to low

Decreased

All stages

Conversion too high.

Check flows and pressures

against design guidelines

Reduce conversion rate. Calibrate

sensors. Increase analysis and data

collection.

RO System Troubleshooting

PRoblem

coRRective actioN

General

high Product Water tDs

Membrane frozen, high temp, or backpressure.

Replace membrane.

Membrane attack by chlorine Carbon pre-filter may be exhausted.

Replace filter and membrane.

Product seal on end cap. Determine if seal or O-ring is bad.

Replace as needed.

No Product Water or Not enough Product Water

Feed water shut off.

Turn on feed water.

Low feed pressure. Feed pressure must be at least 20psi.

Consider booster pump.

Pre-filter cartridge clogged.

Replace pre-filter cartridge.

Membrane fouled.

Determine and correct cause; replace or clean membrane.

Product check valve stuck.

Clean or replace check valve.

Low pump discharge pressure

Adjust reject valve or replace pump

Low feed water temperature

Increase membrane feed pressure or heat the feed water.