Watts SS263AP User Manual

Series ss-263ap, Lead free, Compact stainless steel water regulators

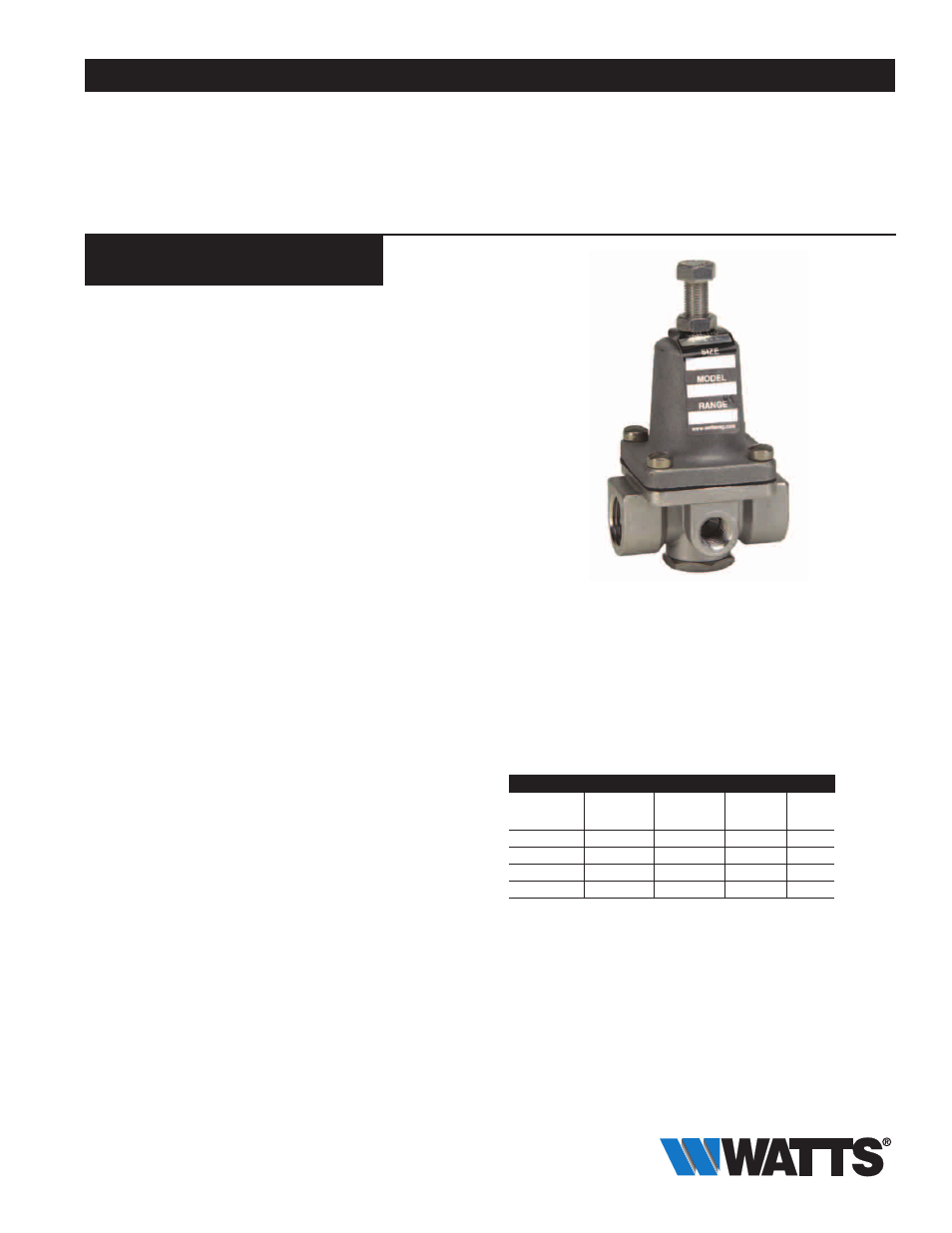

Series SS-263AP

Compact Stainless Steel

Water Regulators

Sizes:

1

/

4

"-

1

/

2

" (8-15mm)

Series SS-263AP Compact Stainless Steel Water Regulators

are designed for use with deionized water, chemical solutions,

high purity water purification systems and low pressure steam,

15psi (1.0 bar), applications.

Features

• Rugged investment cast stainless steel body and cage

• Stainless steel adjusting screw

• Oversized orifice

•

1

/

4

" (8mm) gauge port

Materials

Body:

Stainless steel ASTM-351-CF8M

Spring Cage:

Stainless steel ASTM-351-CF8M

Disc:

Buna-N (FDA) stainless steel stem

Diaphragm:

Reinforced Buna-N (FDA)

Bottom Plug:

Stainless steel

Bottom Spring: Stainless steel

Trim:

Viton

®

*

*Viton

®

is a registered trademark of DuPont Dow Elastomers.

Options

add suffix:

G

pressure gauge

X

slotted adjusting screw

See Pressure -Temperature section for reduced pressure

range options

Specifications

A compact lead free* water regulator shall be installed on

deionized water purification or chemical handling systems as

indicated on the plans. Regulator shall have a stainless steel

body and cage and oversized orifice. Regulator shall be a Watts

Series SS-263AP.

Pressure – Temperature

Temperature Range: 33ºF –120ºF (0.5ºC – 49ºC)

Maximum Operating Pressure: 400psi (27.6 bar)

Reduced Pressure Range:

SS263AP

3-Way

LEAD FREE

*

* The wetted surface of this product contacted by consumable

water contains less than 0.25% of lead by weight.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials with-

out prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

For Residential, Commercial and OEM Applications

ES-SS-263AP

Job Name –––––––––––––––––––––––––––––––––––––––––––

Contractor ––––––––––––––––––––––––––––––––––––––––––––

Job Location –––––––––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Engineer –––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No. ––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Representative ––––––––––––––––––––––––––––––––––––––––

OPTION SUFFIX

RANGE

STD SET AT

psi

bar

psi

bar

A

1-25

0.1-1.8

10

0.7

B

3-50

0.2-3.5

15

1.0

C

10-125

0.7-8.8

25

1.8

D

20-175

3.5-12.3

50

3.5

E

100-300

7.0-21.0

125

8.8