Automatic shift valve data, Bic 1000 specification drawing – Watts BIC-1000 User Manual

Page 5

H

Height from

Flange To Top

ITEM

QTY

DESCRIPTION

MATERIAL

SIZE

CONNECT

1

1

SHUT-OFF VALVE

Consult Factory

FLANGE

2

1

STRAINER - WYE

304 SS / ZN PLATED FLG

FLANGE

3

1

DIAPHRAGM ACTUATED CONTROL VALVE

FBE / DI / SST

FLANGE

4

1

FLANGE X THREAD ADAPTOR

304 SS / ZN PLATE STEEL

FLANGE

5

1

BACKFLOW PREVENTER - WATTS 009M2PCQT

TEFLON COATED BRONZE

FLG X GRV

6

1

GROOVE COUPLER

EPOXY COATED DI

GROOVE

7

1

OUTLET HEADER

304 SST

FLANGE

8

1

RELIEF VALVE

BRASS / BRONZE

FLANGE

9

1

SHUT-OFF VALVE

Consult Factory

FLANGE

10

3

SPACER FLANGE - SLOTTED - NOT SHOWN

304 SST

FLANGE

NOTE: See specific component specifications or literature for detailed component material descriptions

FLOW RATE CAPACITIES - GPM

PRESSURES - PSI

LINE SIZE

CONTINUOUS

INTERMITTENT*

MINIMUM

MAX INLET

MIN DP

SET POINT RANGE

2

160

220

1

170

20

40 - 120

3

320

480

30

170

20

40 - 120

4

500

750

50

170

20

40 - 120

6

1000

1500

115

170

20

40 - 120

*Based on:

a - 150% Emergency Flow rate through Backflow Preventer (90 Minute UL/FM Test)

b - Max Capacity through the ACV for a system with a 20psi or greater pressure reduction requirement

FLOW RATES - GPM

FALL OFF FROM SET POINT @ - PSI

LINE SIZE

20% CONT

20% INTERMIT

20% CONT

20% INTERMIT

100% CONT

100% INTERMIT

2

32

44

4

5

8

18

3

64

96

3

3

4

11

4

100

150

5

6

7

9

6

200

300

4

4

5

6

X

Hydro test the fully assembled Valve Station to 175psi for 5 minutes without leakage.

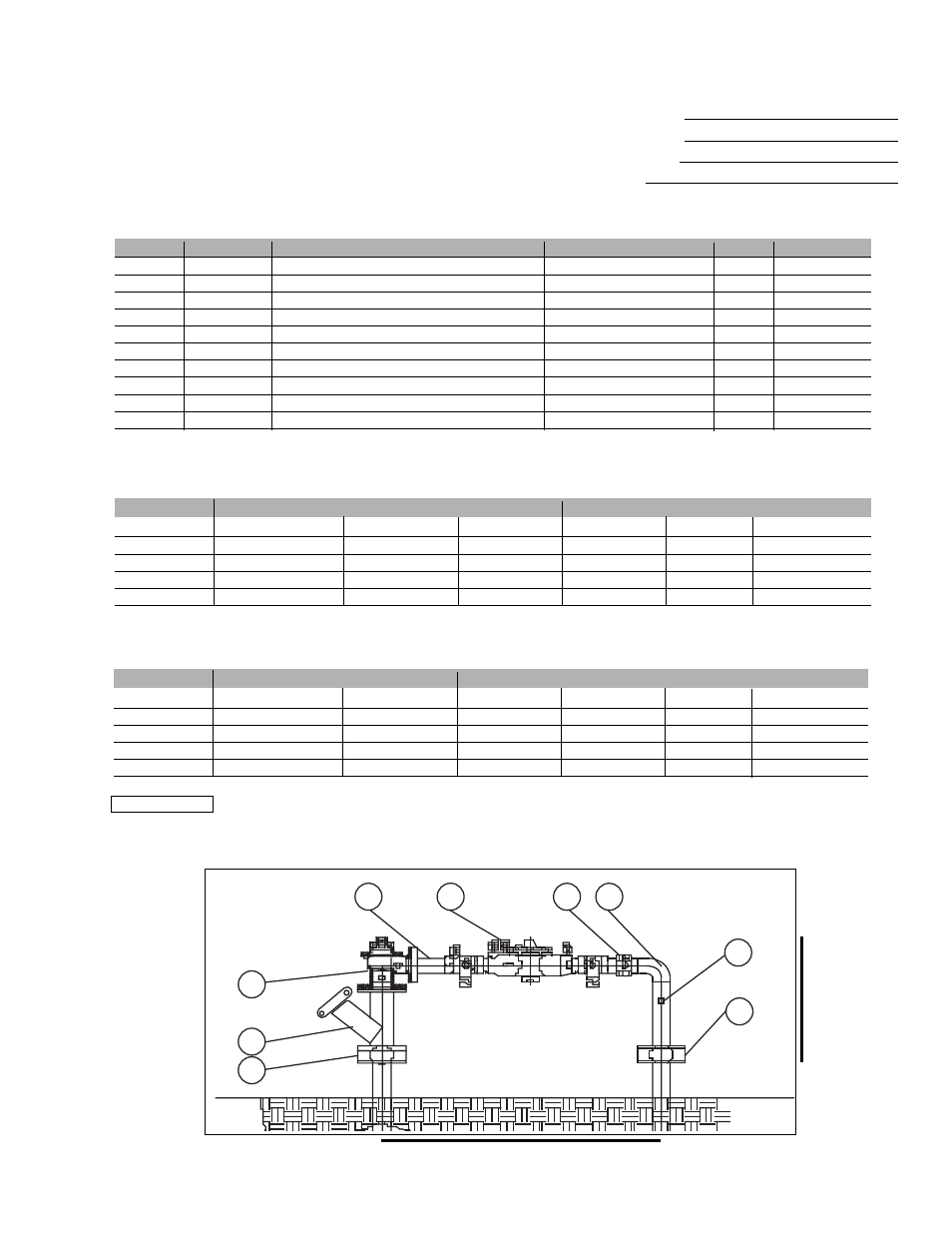

Typical Configuration Drawing - Above Ground Installation

AUTO SHIFT VALVE

Typical Performance Data

CC - Center Line of Inlet / Outlet Pipes

1

2

3

4

5

6

7

8

9

5

Automatic Shift Valve Data

BIC 1000 Specification Drawing

Configuration Data -

Typical BOM and Drawing

Valve Station Component Requirements

JOB NAME

CUSTOMER

ENGINEER

RFQ#