G. troubleshooting ro troubleshooting guide, Motor troubleshooting guide – Watts PWR4011 User Manual

Page 6

6

G. Troubleshooting

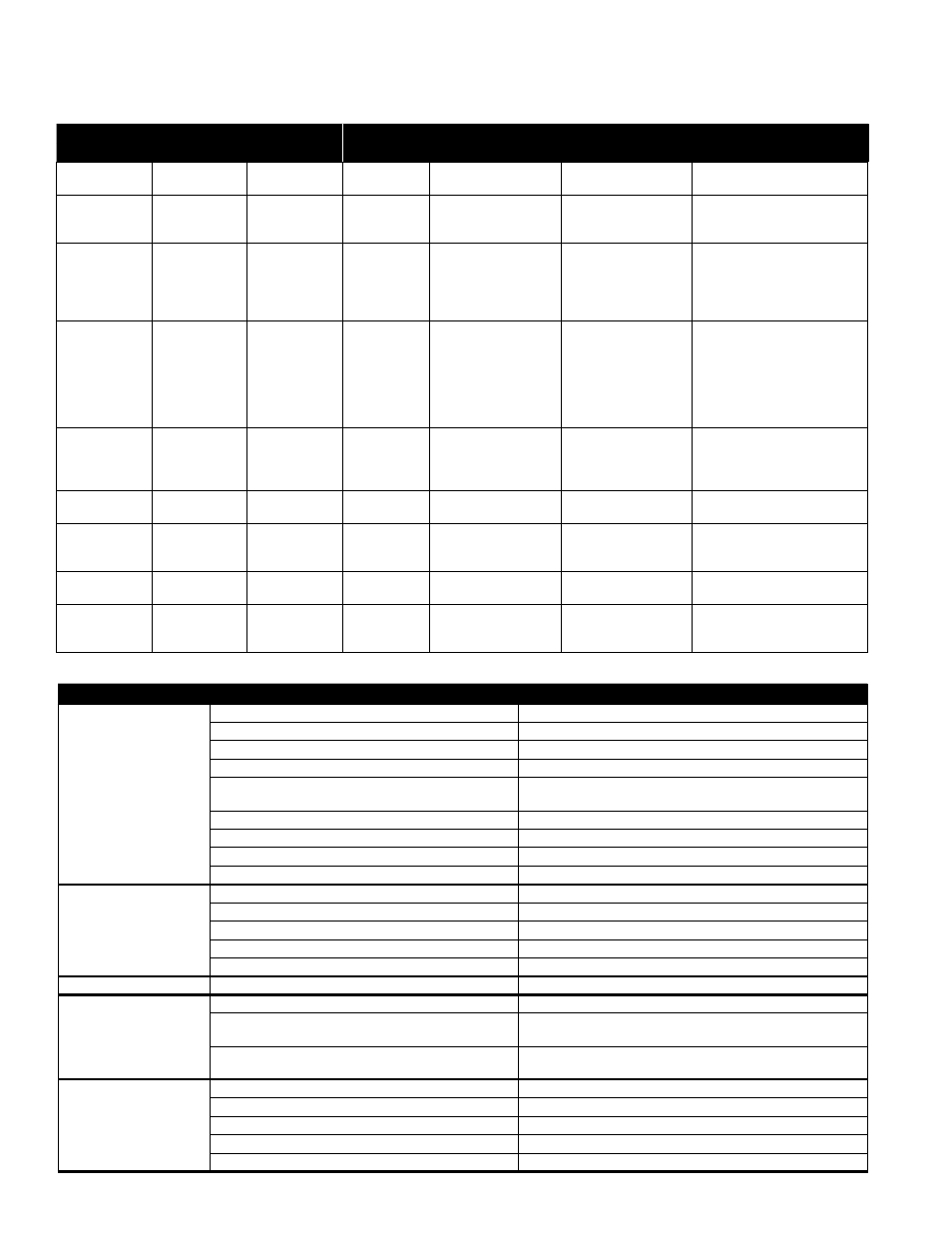

RO Troubleshooting Guide

sYmPtoms

salt PassaGe

PeRmeate FloW

PRessuRe DRoP

location

Possible causes

veRiFication

coRRective action

Normal to increased Decreased

Normal to increased Predominantly

first stage

Metal oxide

Analysis of metal ions in

cleaning solution.

Improved pretreatment to remove met-

als. Cleaning with acid cleaners.

Normal to increased Decreased

Normal to increased Predominantly

first stage

Colloidal fouling

SDI measurement of feed/

X-ray diffraction analysis of

cleaning sol. residue.

Optimize pretreatment system for

colloid removal. Clean with high pH,

anionic detergent formulation.

Increased

Decreased

Increased

Predominantly

last stage

Scaling (CaSO

4

, CaSO

3

,

BaSO

4

, SiO

2

)

Analysis of metal ions in

cleaning sol. Check LSI of

reject. Calculate maximum

solubility for CaSO

4

, BaSO

4

,

SiO

2

in reject analysis.

Increase acid addition and scale

inhibitor for CaSO

3

and CaSO

4

. Reduce

recovery. Clean with an acid formula-

tion for CaCO

3

, CaSO

4

and BaSO

4

.

Normal to moderate

increase

Decreased

Normal to moderate

increase

Can occur in any

stage

Biological fouling

Bacteria count in permeate

and reject. Slime in pipes

and vessels.

Shock dosage of sodium bisulfite.

Continuous feed of low conc. Of

bisulfite at reduced pH. Formaldehyde

sterilization. Clean with alkaline anionic

surfactant. Chlorine dosage up-stream

with subs. Dechlorination. Replace

cartridge filters.

Decreased or

moderately

increased

Decreased

Normal

All stages

Organic fouling

Destructive testing, e.g. IR

reflection analysis.

Optimization of pretreatment system

(e.g. coagulation process.) Resin/

activated carbon treatment. Clean with

high pH detergent.

Increased

Increased

Decreased

Most severe in

the first stage

Chlorine oxidant attack

Chlorine analysis of feed.

Destructive element test.

Check chlorine feed equipment and

dechlorination equipment.

Increased

Increased

Decreased

Most severe in

the first stage

Abrasion of membrane by

crystalline material

Microscopic solids analysis

of feed. Destructive ele-

ment test.

Improved pretreatment. Check all filters

for media leakage.

Increased

Normal to increased Decreased

At random

O-ring leaks, End or side

seal glue leaks.

Probe test. Vacuum test.

Colloidal material passage.

Replace O-rings. Repair or replace

elements.

Increased

Normal to low

Decreased

All stages

Conversion too high.

Check flows and pressures

against design guidelines

Reduce conversion rate. Calibrate

sensors. Increase analysis and data

collection.

Motor Troubleshooting Guide

PRoblem

Possible cause

coRRective action

Motor fails to start

Blown fuses

Replace fuses with proper type and rating

Overload trips

Check and rest overload in starter.

Improper power supply

Check to see that power supplied agrees with motor nameplate and load factor.

Open circuit in winding or control switch

Indicated by humming sound when switch is closed.

Mechanical failure

Check to see if motor and drive turn freely. Check bearing and

lubrication.

Short circuited stator

Indicated by blown fuses. Motor must be rewound.

Poor stator coil connection

Remove end bells, locate with test lamp.

Rotor defective

Look for broken bars or end ring.

Motor may be overloaded

Reduce load.

Motor Stalls

One phase connection

Check lines for open phase.

Wrong application

Change type or size. Consult manufacturer.

Overload motor

Reduce load.

Low motor voltage

See that nameplate voltage is maintained. Check connection.

Open circuit

Fuses blown, check overload relay, stator and push buttons.

Motor runs and then dies down

Power failure

Check for loose connections to line, to fuses and to control.

Motor does not come up

to speed

Not applied properly

Consult supplier for proper type.

Voltage too low at motor terminals because of line drop.

Use higher voltage on transformer terminals or reduce load. Check connections.

Check conductors for proper size.

Broken rotor bars or loose rotor.

Look for cracks near the rings. A new rotor may be required as repairs are usu-

ally temporary.

Motor takes too long to acceler-

ate

Open primary circuit

Locate fault with testing device and repair.

Excess loading

Reduce load.

Poor circuit

Check for high resistance.

Defective squirrel cage rotor

Replace with new rotor.

Applied voltage too low

Get power company to increase power tap.