Ii. controls, indicators, and components, Iii. operation, A. installation – Watts PWR4011 User Manual

Page 3: B. plumbing connections

3

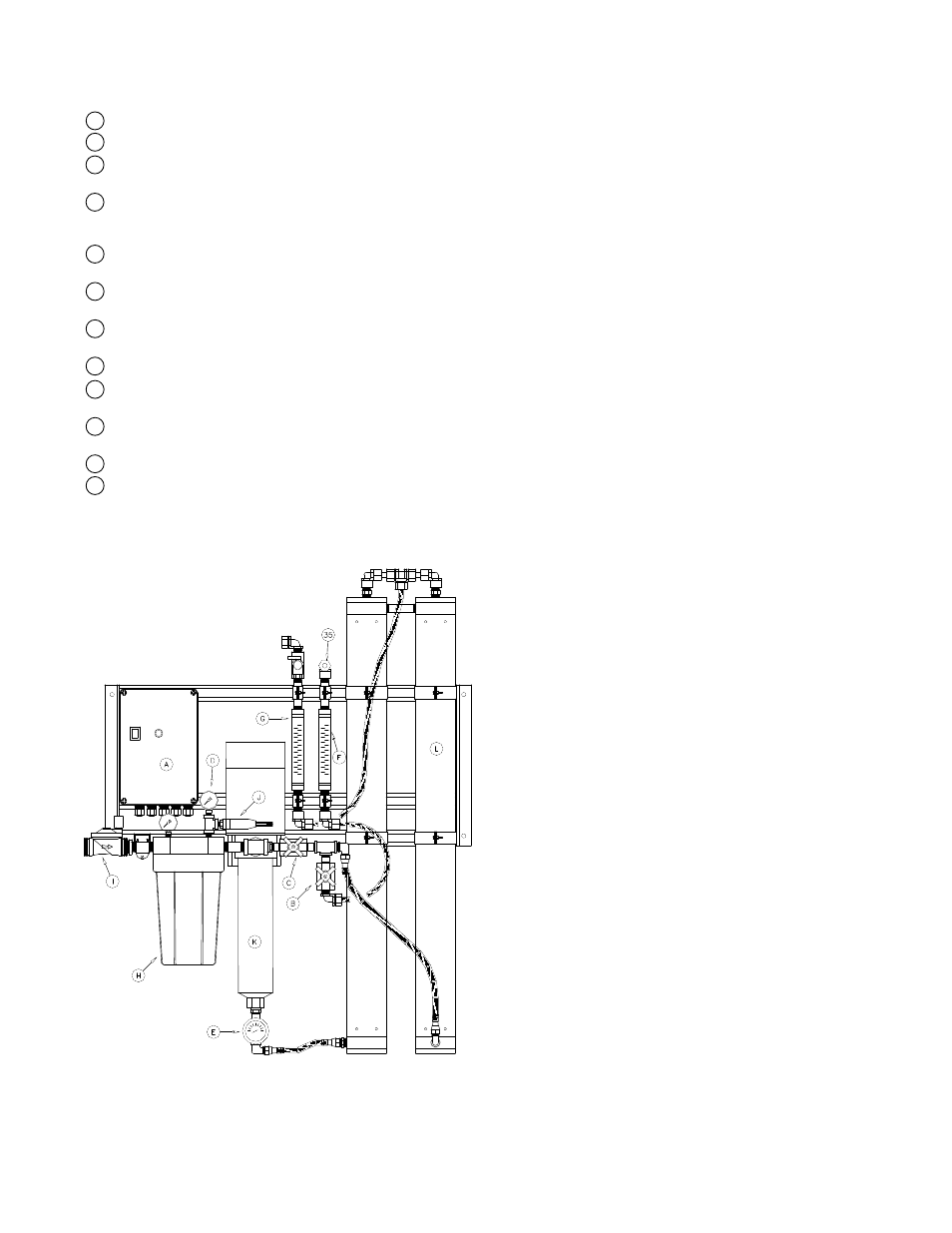

Figure 1

II. Controls, Indicators, and

Components

(See Figure 1)

A. Controller - Controls the operation of the system.

B. Reject Control Valve - Controls the amount of reject flow.

C. Reject Recycle Control Valve – Controls the amount of recycle

flow.

D. Prefilter Pressure Gauges - Indicates the inlet and outlet pres-

sure of the prefilter. The difference between these two gauges is

the prefilter differential pressure.

E. Pump Discharge Pressure Gauge - Indicates the pump dis-

charge pressure.

F. Reject Flow Meter - Indicates the reject flow rate in gallons per

minute (gpm).

G. Product Flow Meter - Indicates the product flow rate in gallons

per minute (gpm).

H. Prefilter Housing - Contains the RO prefilter.

I. Automatic Inlet Valve - Opens when pump is on and closes

when the pump is off.

J. Low Pressure Switch - Sends a signal to the controller if the

pump suction pressure is low.

K. RO Feed Pump - Pressurizes the RO feed water.

L. RO Membrane Vessels - Contains the RO membranes.

III. Operation

A. Installation

1. The water supply should be sufficient to provide a minimum of

20 psig pressure at the design feed flow.

2. Proper pretreatment must be determined and installed prior to

the RO system.

3. A fused high voltage disconnect switch located within 10 feet of

the unit is recommended. This disconnect is not provided with

the RO system.

4. Responsibility for meeting local electrical and plumbing codes

lies with the owner / operator.

5. Install indoors in an area protected from freezing. Space al-

lowances for the removal of the membranes from the pressure

vessels should be provided.

B. Plumbing Connections

Note: It is the responsibility of the end user to ensure that the

installation is done according to local codes and regulations.

1. Connect the pretreated feed water line to the inlet valve (Figure #

1 item I). A feed water shutoff valve should be located within 10

feet of the system.

2. Temporarily connect the outlet of the product water flow meter

to drain. (Figure # 1 item G) The product water line should

never be restricted. Membrane and/or system damage may

occur if the product line is blocked.

3. Connect the outlet of the reject water flow meter to a drain.

(Figure # 1 item F) The reject drain line should never be re-

stricted. Membrane and/or system damage may occur if the

reject drain line is blocked. An air gap must be located between

the end of the drain line and the drain. The use of a standpipe or

other open drain satisfies most state and local codes and allows

for visual inspection and sampling.