Drill hole and connect, Black tube from faucet to the drain saddle, Green tube connection – Watts PWRO4 User Manual

Page 6: Reverse osmosis module mounting, Tube connection (from faucet), Tank tee installation, Check air pressure in the tank, Step 5 step 6, Step 7, Step 8

6

Drill hole and Connect

3

⁄

8

" Black Tube

from Faucet to the Drain Saddle

IMPORTANT: The black

3

⁄

8

" drain tube must be as SHORT and

STRAIGHT as possible to the drain saddle, making a downward

slope from faucet to drain saddle to allow for proper drainage.

This is a gravity fed line and if there is any bend or dip in the

tube, the rinse water will not flow into the drain properly. Water

may back up and come out the air gap hole in the back of the

faucet.

Step A – With the drain saddle secured

onto the drain pipe, using a

1

⁄

4

"

drill bit installed in your electric

drill, insert the drill bit through

the opening in the drain saddle

and drill through the drain pipe .

Caution: It is very important to keep the drill centered to pre-

vent damage of the drain saddle while drilling.

Step B – Measure the

3

⁄

8

" black tube

from faucet to the drain saddle

on the drain pipe and make

a straight cut to the correct

length .

Step C – Slip black tube through black

compression nut . Insert black

tube into the opening in the

drain saddle and hand tighten the black nut, and add

1

⁄

4

turn with a wrench .

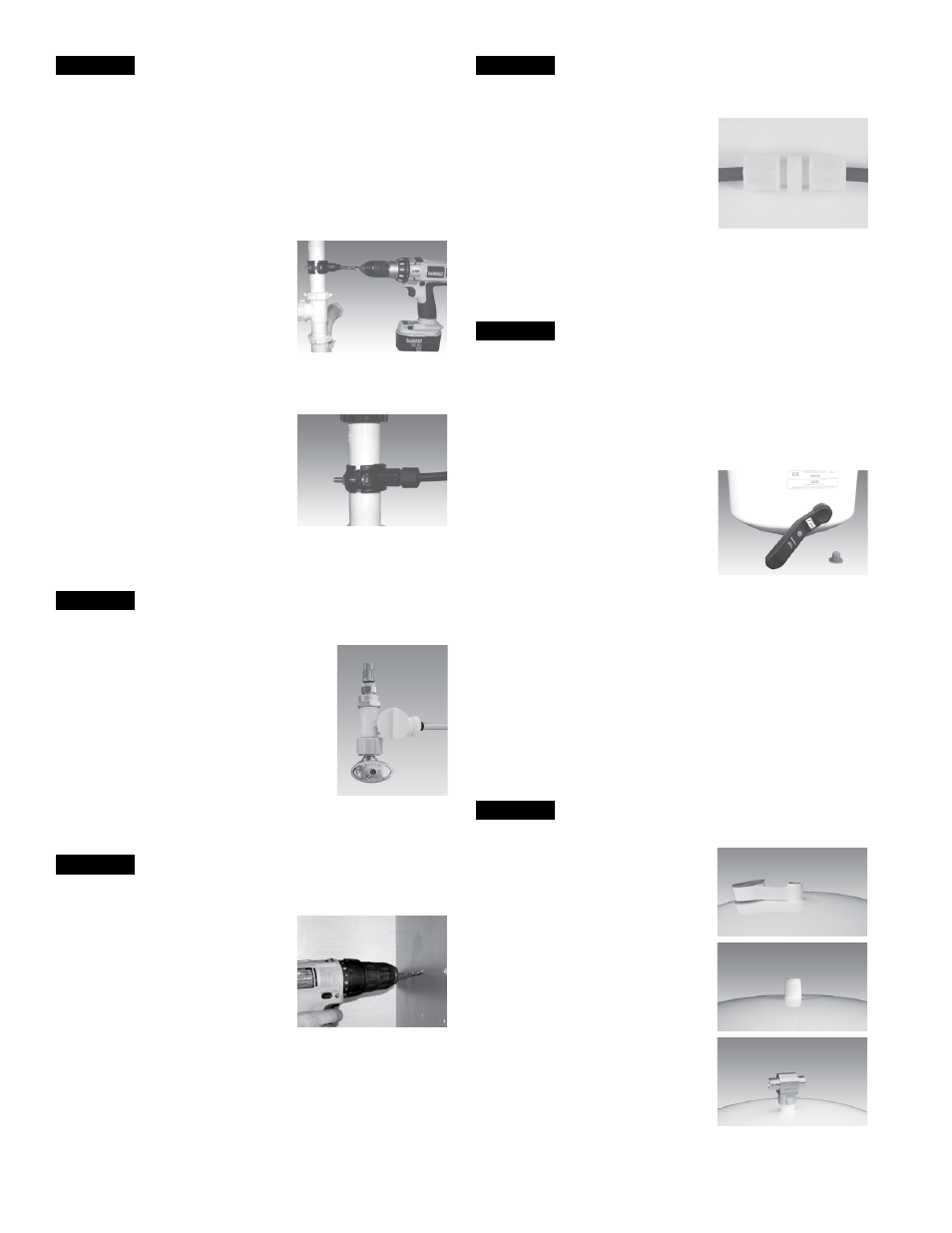

STEP 5

STEP 6

Green Tube Connection

Step A – Locate green tube attached to the

RO Module . Insert the open end of

the green

1

⁄

4

" tube into the open

1

⁄

4

"

Quick-Connect fitting on the Adapt-

A-Valve™ making sure the tube is

pushed in all the way to the tube

stop .

Step B – Connect the green tube from the RO

module to the Adapt-A-Valve™ that

is connected to the angle stop valve .

Leave enough tube so it is not kinked and cut the tube to

the desired length .

STEP 7

Reverse Osmosis Module Mounting

Step A – Determine best location for the

RO module to be mounted to

allow for future system main-

tenance . The parts bag has 2

self-tapping screws . Using an

electric drill with a Phillips bit,

screw them into the cabinet

wall 6" apart and 16" from the

bottom of the cabinet .

Note: Do not cut any RO system tubes at this time

STEP 8

Red

1

⁄

4

" Tube Connection (from faucet)

Step A – Using the white plastic union

found in the parts bag, deter-

mine where the

1

⁄

4

" red tubing

from the faucet and the

1

⁄

4

" red

tubing from the RO membrane

housing would join together

comfortably . Cut red tube from

RO faucet to length leaving a

straight cut edge . Insert the red tube from RO faucet in one

end of the white plastic union and the red tube from RO

membrane housing in the other end . Use a

5

⁄

8

" wrench to

tighten both of the white plastic nuts securely .

STEP 10

Tank Tee Installation

Step A – Wrap (7 to 12 turns) of Teflon

®

tape clockwise around the

male pipe threads (MPT) on the

Stainless Steel fitting on top of

the tank .

NOTE: Do not let the tape cover the

opening.

Step B – Thread the plastic elbow (sup-

plied in the parts bag) onto the

stainless steel connection on

the top of tank . Tighten using

an adjustable wrench. Do not

over tighten as plastic could

crack .

STEP 9

Check Air Pressure in the Tank

Note: Check air pressure when tank is empty of water!

Check air pressure in the storage tank when you notice a de-

crease in available water from the RO system. Air can be added

with a bicycle pump using the schrader valve that is located on

the lower side of the tank behind the blue plastic cap.

Step A – Turn off the incoming water

supply to the RO by turning the

knob on the Adapt-A-Valve™

clockwise until it stops . (Follow

the green tube away from the

RO system to find the Adapt-A-

Valve™ .)

Step B – Open the RO Faucet and allow water to drain from the tank

until it is completely empty .

Tip: When water from the RO faucet slows to a trickle with the

faucet still in the open position, you may add air to the tank to

purge any left over water. This will ensure that the tank is com-

pletely empty.

Step C – Once all water in the tank is purged, check air pressure us-

ing an air pressure gauge . It should read between 5 - 7psi .

(Digital air pressure gauge is recommended)

Step D – Follow startup procedure on Page 7 .

Teflon

®

is a registered trademark of E .I . Dupont de Nemours & Company .