Installing the chemical-resistant models – Banner U-GAGE QT50U Ultrasonic Sensors User Manual

Page 6

Action

Result

Position the target at the desired midpoint for the sensing

window.

Click the TEACH button.

Output LED changes to flashing red

3. Teach the second limit.

Action

Result

Without moving the target, click the button again.

The sensor stores sensing window and the Output LED turns solid

amber. The sensor returns to Run mode.

Output OFF

Taught Position

(e.g., wall or floor)

Position

-100 mm

Position

+100 mm

Sensor

Output

ON

Sensor

Output

OFF

Any object in this area will switch the output,

whether or not the object returns a good signal to the sensor.

Sensing Range

200 mm

Output ON

Figure 7. An application for Auto-Window feature (retroreflective mode)

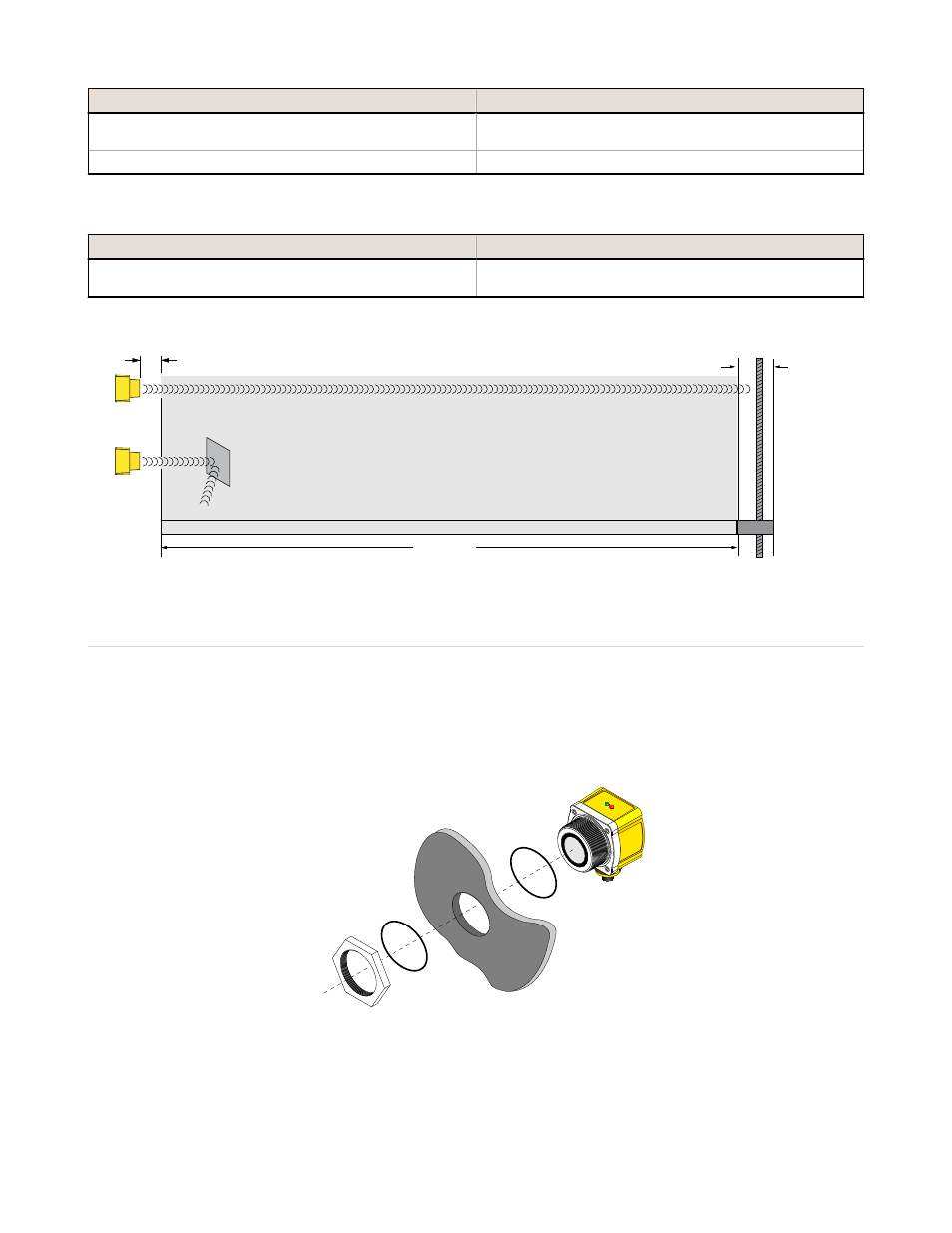

Installing the Chemical-Resistant Models

The sensor may be threaded directly into the side of a tank (see dimensions for hole diameter and thread specifications),

or into a non-threaded hole, using the included threaded nut. Recommended through-hole size: 56.5 ± 0.5 mm.

For a non-threaded hole, install an o-ring onto the flange, and insert the flange completely into the hole until the sensor

front surface is against the tank’s exterior surface. Place the other o-ring into the groove on the Teflon nut, and thread the

nut onto the flange. Tighten enough to eliminate gaps between the flange and the tank surface. This will ensure that the o-

rings are fully compressed.

QT50U Chemical-Resistant Sensor

Tank Section

O-Ring

O-Ring

Threaded Teflon

Nut (included)

Figure 8. Installing a chemical-resistant sensor model into a threaded hole in a tank

U-GAGE QT50UVR Series Sensors

6

www.bannerengineering.com - tel: 763-544-3164

P/N 117764 Rev. F