45lm series modules, Measuring excess gain and contrast – Banner Q45 Laser DC Series User Manual

Page 4

45LM Series Modules

4

P/N 63416 rev. A

Banner Engineering Corp.

•

Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

1 2 3 4 5

6 7

Measuring Excess Gain and Contrast

The seven-element LED array, available on models 45LM58D and 45LMD, may be used

to measure the excess gain and contrast in any sensing situation and during sensor

installation and maintenance.

Excess gain is a measurement of the amount of light energy falling on the receiver of

a photoelectric sensor over and above the minimum amount necessary to operate the

sensor’s amplifier. Excess gain is expressed as a ratio:

Excess gain (E.G.) = light energy falling on receiver

amplifier threshold

The amplifier threshold is the point at which the sensor’s output switches. The Q45’s

threshold corresponds to the #3 level of the LED array. That is, when LEDs #1 through

#3 are lit, the excess gain of the received light signal is about “1x.”

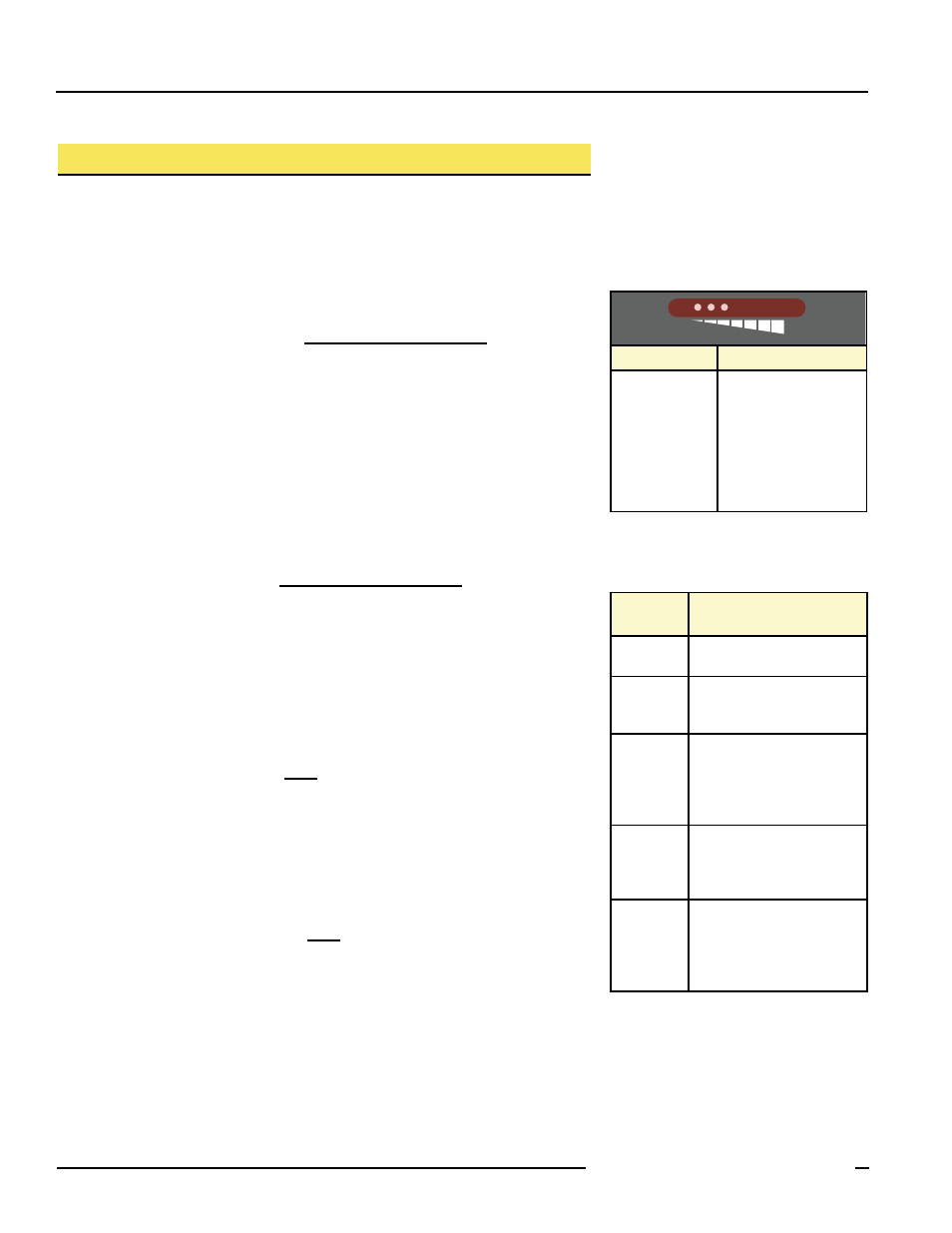

The table at right (Figure 3) shows how excess gain relates to the LED array indicator.

Contrast is the ratio of the amount of light falling on the receiver in the “light” state

as compared to the “dark” state. Contrast is also referred to as “light-to-dark ratio.”

Optimizing the contrast in any sensing situation will increase the reliability of the

sensing system. Contrast may be calculated if excess gain values are known for both

the light and dark conditions:

Contrast = Excess gain (light condition)

Excess gain (dark condition)

To determine the contrast for any sensing application, present both the “light” and

“dark” conditions to the Q45, and read the signal for each. Take the ratio of the two

numbers (from Figure 3) that correspond to the highest LED numbers registered for

the “light” and “dark” conditions.

For example, if LEDs #1 through #6 come ON in the “light” condition and LEDs #1 and

#2 come ON in the “dark” condition, the contrast (referring to Figure 3) is calculated as

follows:

Contrast = 6x = 12

0.5x

This value is expressed as “12:1” or “twelve-to-one.”

The best sensor adjustment will cause all seven LEDs to come ON for the “light”

condition, and will cause no LEDs to come ON in the “dark” condition. In this situation

(such as an application in which a box breaks the beam of an opposed mode emitter

and receiver):

Contrast is greater than 8x = 32:1

0.25x

Of course, it is not always possible to adjust a sensor to maintain this much contrast.

However, it is important to always adjust a sensor for the greatest amount of contrast

possible for any sensing situation. The LED signal strength indicator array makes this

easy. Figure 4 gives general guidelines for contrast values.

Figure 3. The 7-segment LED array and its

corresponding excess gain values

Contrast

Ratio

Recommendation

1.2 or

less

Unreliable. Use an

alternative sensing scheme.

1.2 to 2

Poor contrast. Minor

sensing system variables

will affect sensing reliability.

2 to 3

Low contrast. Sensing

environment must remain

perfectly clean and all other

sensing variables must

remain stable.

3 to 10

Good contrast. Minor

sensing system variables

will not affect sensing

reliability.

10 or

greater

Excellent contrast. Sensing

should remain reliable as

long as the sensing system

has enough excess gain for

operation.

Figure 4. Contrast values and corresponding

guidelines

LED Number

Approximate Gain

#1

#2

#3

#4

#5

#6

#7

0.25x

0.5x

1.0x

2.0x

4.0x

6.0x

8.0x

p/n 63416 Rev. B