Omni-beam sensor heads, Measuring sensing contrast, Contrast values and corresponding guidelines – Banner OMNI-BEAM Series User Manual

Page 7

OMNI-BEAM Sensor Heads

page

7

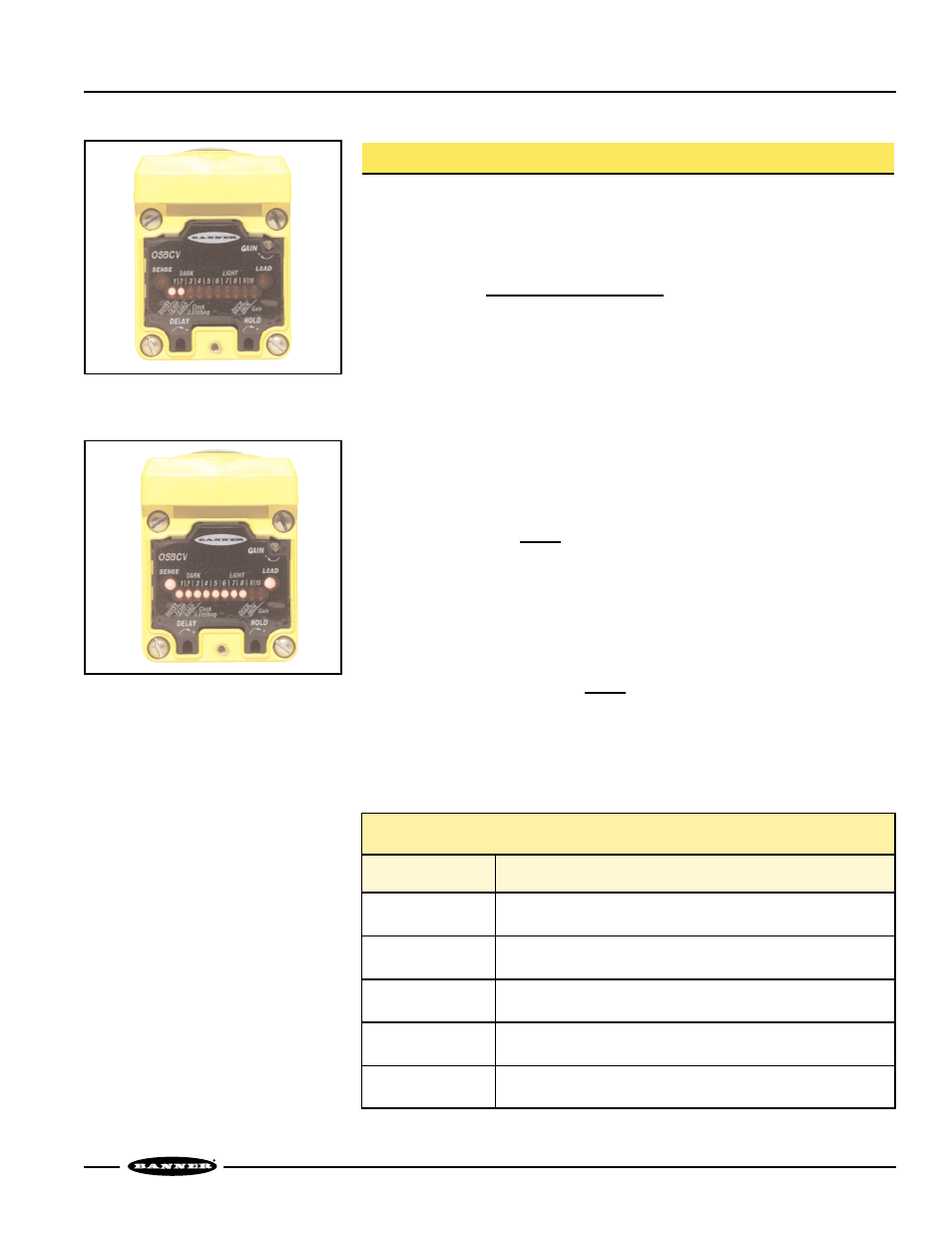

Figure 8. Dark condition example:

D.A.T.A. system LEDs #1

and #2 lit.

Figure 9. Light condition example:

D.A.T.A. system LEDs

#1 through #8 lit.

Measuring Sensing Contrast

Contrast is the ratio of the amount of light falling on the receiver in the “light” state,

compared to the “dark” state (sometimes called “light-to-dark ratio”). Optimizing the

contrast in any sensing situation increases the sensing reliability. Contrast may be

calculated if excess gain values are known for both the light and dark conditions:

Contrast = Excess gain (light condition)

Excess gain (dark condition)

To determine the contrast for any sensing application, present both the Light and Dark

conditions to the OMNI-BEAM, and note how many LEDs in the D.A.T.A. display are

ON for each condition. Compute the ratio from the corresponding excess gain

numbers (from the chart on page 6) for the two conditions.

For example, if LEDs #1 through #8 come ON in the Light condition and LEDs #1 and

#2 come ON in the Dark condition (assuming Standard scale factor), contrast is

calculated as follows:

Light condition: 2.2x excess gain

Dark condition: 0.35x excess gain

Contrast = 2.2x

= 6

0.35x

This value is expressed as 6:1 (“six-to-one”).

The best sensor adjustment will cause all ten D.A.T.A. LEDs to come ON for the Light

condition, and none in the Dark condition. In this situation (such as an application in

which a box breaks the beam of an opposed-mode emitter/receiver pair):

Contrast is greater than

3.7x = 15

0.25x

While it is not always possible to adjust a sensor to maintain this much contrast, it is

important to always adjust for the maximum possible contrast. The D.A.T.A. feature

makes this easy. The chart below gives general guidelines for contrast values.

Contrast Values and Corresponding Guidelines

Contrast

Recommendation

1.2 or Less

Unreliable. Evaluate alternative sensing schemes.

1.2 to 2

Poor Contrast. Use the LOW hysteresis setting and the FINE

scale factor.

2 to 3

Low Contrast. Sensing environment must remain perfectly clean and

all other sensing variables must remain stable.

3 to 10

Good Contrast. Minor sensing system variables will not affect

sensing reliabilty.

10 or Greater

Excellent Contrast. Sensing should remain reliable as long as the

sensing system has enough excess gain for operation.