4 carry-over with sample degassing, 1 determination of the "transfer time, 2 check sample carry-over – Metrohm 837 IC Degasser User Manual

Page 25: Carry-over with sample degassing, Determination of the "transfer time, Check sample carry-over, Ion 4.4

4.4 Carry-over with sample degassing

837 IC (Eluent/Sample/Combi) Degasser/ Instructions for Use 8.837.1003

19

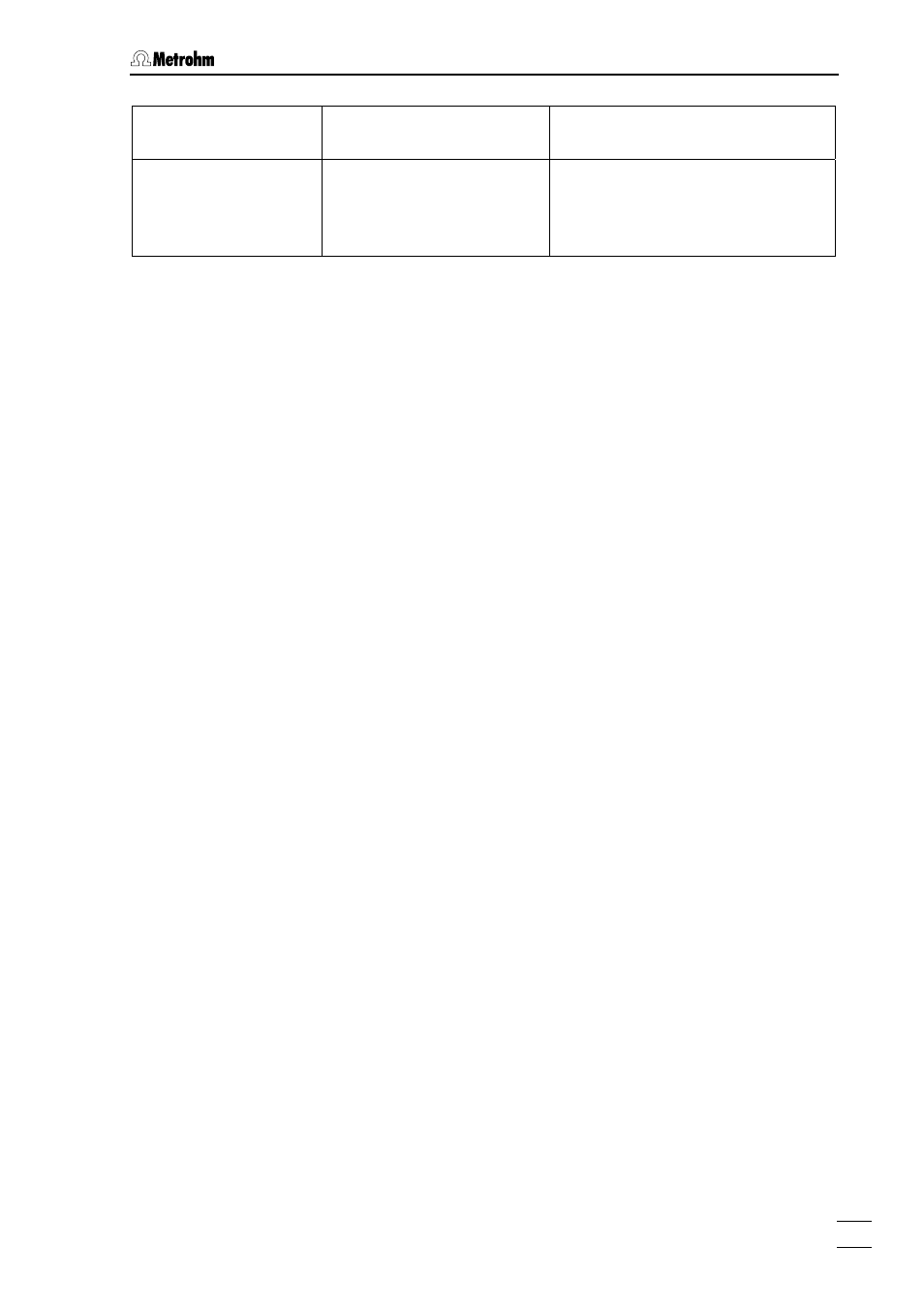

Liquid is leaking from the

exhaust opening (15)

•

Leak in the instrument

•

Contact Metrohm Service

LED "Abs <65" (4) does not

light up (while pump is run-

ning)

•

Leak in vacuum chamber

•

Vacuum pump does not work

properly

•

Contact Metrohm Service

•

Contact Metrohm Service

4.4

Carry-over with sample degassing

If you work with sample degassing (837 IC Sample/Combi Degasser),

you should rinse longer (with the succeeding sample) because of the

longer "Transfer time" (The time the sample needs to flow from the sam-

ple vial through the degasser till the end of the sample loop). The rinse

time should be at least 2-3 longer than the "Transfer time", to minimize

carry-over effects. The "Transfer time" itself depends on pumping

capacity, total capillary volume and volume of the gas removed by the

degasser (thus on the amount of gas in the sample).

4.4.1

Determination of the "Transfer time"

To determine the "Transfer time", the system (pump tube, tubing con-

nections, Degasser capillary, sample loop) should be emptied. Pump

air through the system for some minutes, until all liquid is displaced by

air. Then, aspirate a typical (for your later application) sample, and

measure the time the sample needs to flow from the sample vial till the

end of the sample loop. The migration of the top of the sample flow can

be observed with the eye. The measured time is the "Transfer time". The

rinse time should be at least 2-3 times longer (Check carry-over, see

section 4.4.2).

4.4.2

Check sample carry-over

Sample carry-over and required rinsing time can be checked by spiking

a sample with an ion (which is not or only in small amounts contained

by the original sample); for example phosphate for mineral water sam-

ples. Procedure:

1. Prepare two samples:

a. Sample A: a sample, typical for your application

b. Sample B: Sample A - spiked with a "Spike-Ion"

2. Let sample A flow through the sample flow path (for the duration

of the rinsing time), inject it and measure

3. Let then flow sample B through the sample flow path (for the du-

ration of the rinsing time), inject it and measure

4. Then let again sample A flow through the sample stream (for the

duration of the rinsing time), inject it and measure

The ratio of the peak area of the "Spike-Ion" in the second measurement

of sample A to the peak area in the measurement of sample B reflects

the extend of the sample carry-over. The smaller that ratio is, the