6 troubleshooting, 7 technical specifications – Metrohm 930 Compact IC Flex Oven/SeS/PP User Manual

Page 103

■■■■■■■■■■■■■■■■■■■■■■

6 Troubleshooting

930 Compact IC Flex Oven/SeS/PP (2.930.2500)

■■■■■■■■

95

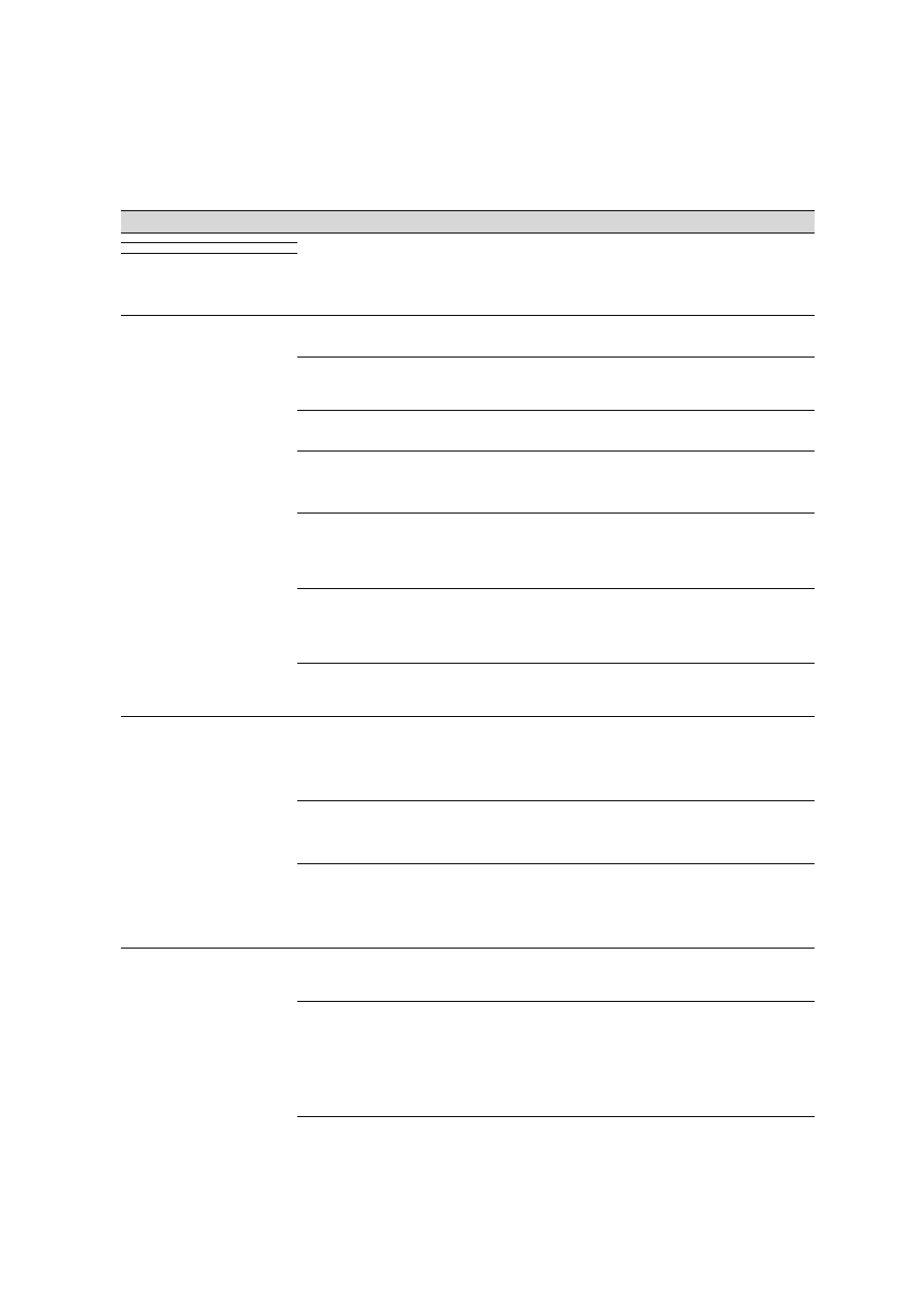

6 Troubleshooting

Problem

Cause

Remedy

Marked drop in

pressure.

Leak in the system.

Check all capillary connections and seal leaks,

if necessary (see Chapter 3.2, page 13).

The baseline has a

large amount of

noise.

The eluent path has a leak.

Check the eluent path and fix the leak.

High-pressure pump – Con-

taminated pump valves.

Clean pump valves (see Chapter 5.7, page 64).

The eluent path is blocked.

Check the eluent path and fix the blockage.

High-pressure pump –

Defective piston seals.

Replace the piston seals (see Chapter 5.7,

page 64).

MCS – The

CO

2

adsorber cartridge is

depleted.

Replace the CO

2

adsorber cartridge (see Chap-

The pulsation absorber is

not connected or is defec-

tive.

Connect (see Chapter 3.9, page 25) or replace

the pulsation absorber.

MCS – The vacuum pump is

defective.

Contact Metrohm Service.

The baseline is drift-

ing.

Thermal equilibrium is not

yet attained.

Condition (see Chapter 3.20, page 55) the

instrument with the column oven (see Chapter

3.5, page 19) switched on.

Leak in the system.

Check all capillary connections and seal leaks,

if necessary (see Chapter 3.2, page 13).

The organic solvent in the

eluent is evaporating.

■

Check the eluent bottle cap (see Chapter

3.6, page 20).

■

Constantly stir the eluent.

The pressure in the

system markedly

increases.

The inline filter

(6.2821.120) is blocked.

Replace the filter (6.2821.130) .

Suppressor blocked.

■

Regenerate the suppressor (see Chapter

5.11.3.2, page 82).

Note: 6.2821.180 pump tubing connection

with filter must be used.