Inspection, Troubleshooting – Bird Technologies 4314C User Manual

Page 34

22

If there is evidence of contamination inside the line section, the reachable por-

tions should be cleaned and the interior carefully blown out.

Do not attempt to remove the RF center conductor under any circumstances.

Any attempt to do so will damage the assembly.

Inspection

Periodic inspections should be performed at six-month intervals.

•

Inspect the meter for a cracked meter glass.

•

Inspect wattmeter line section for a damaged or missing latch and pivot

pin assembly.

•

Inspect all “QC” connectors for bent, broken, or missing pins.

Troubleshooting

Due to its complexity, field repair of the Model 4314C Thruline Wattmeter is rec-

ommended only for certain malfunctions. Only those functions within the scope

of normal maintenance are listed.

If a malfunction is not listed or not corrected by the listed corrective actions,

notify a qualified service center for further instructions.

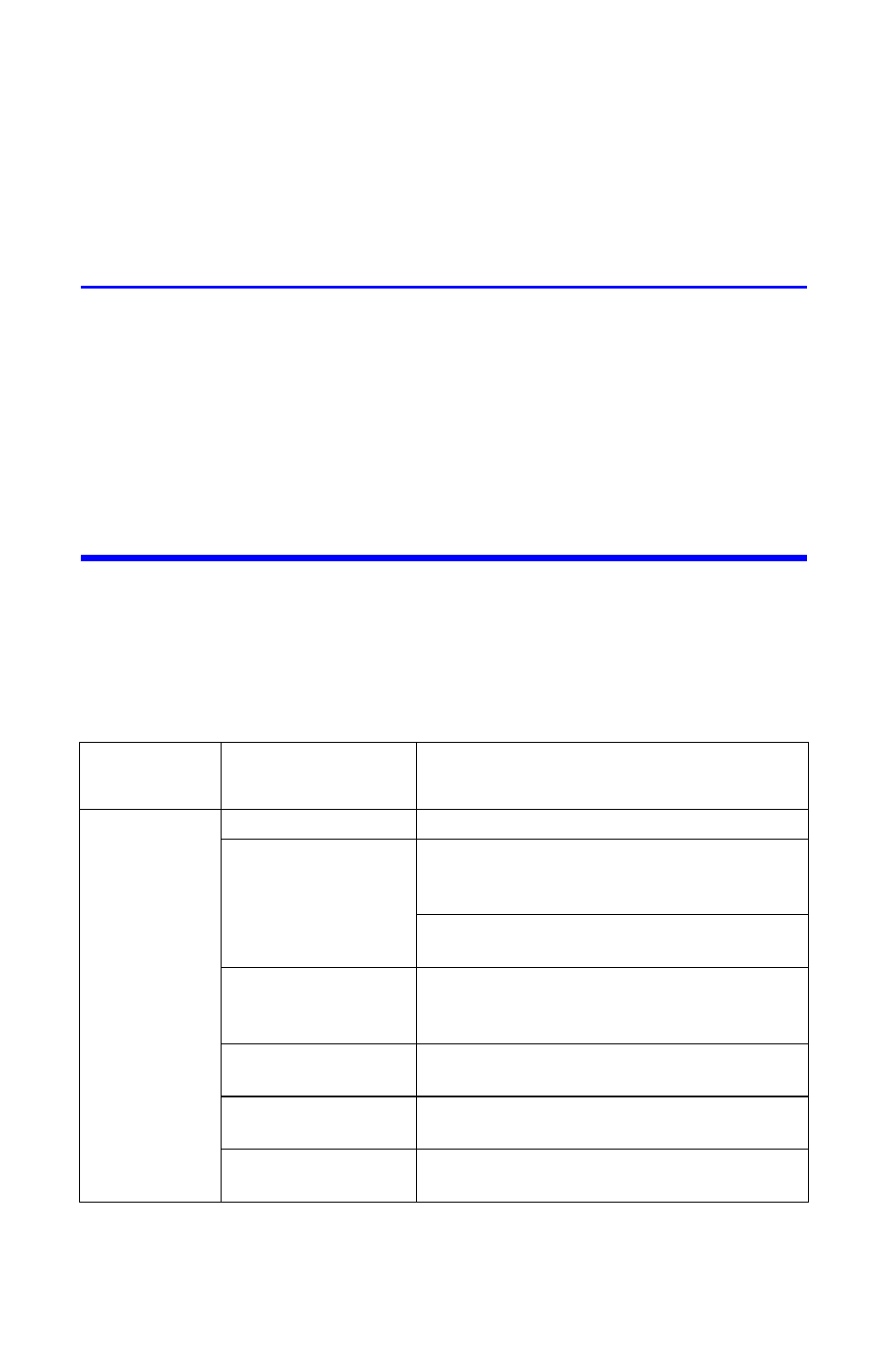

PROBLEM

POSSIBLE

CAUSE

CORRECTION

No meter

indication

(CW or PEAK)

No radio frequency

Turn on transmitter.

Faulty RF section

assembly

Check transmitter operational conditions,

refer to operating instruction manual of

equipment used.

Check connections, interconnecting

cables, and auxiliary in-line equipment.

Arrow on element

pointing in wrong

direction

Rotate element so that arrow points in

direction of RF power flow.

Meter burned out or

damaged

Replace meter. See “Replacing the Meter”

on page 25.

No pick-up from DC

contact

Clean line section and element.See

“Cleaning” on page 21.

Defective Plug-In

Element

Check element. Replace element if

defective.