2 smartire, Tpms system q&a – Bendix Commercial Vehicle Systems SmarTire Trailer-Link Op Manual User Manual

Page 46

46

7.2 SmarTire

®

TPMS System Q&A

7.2.1 Q: A trailer tire continues to show a deviation value/alert although

it was aired up properly.

A: Set the Cold Inflation Pressure value (CIP) for each trailer axle to make

sure it matches that of the intended inflation value for the tire in question.

To do so, please refer to Section C, 4.2.2 as well as the inflation tables in

Section A under Section 1.4. If the CIP value is matched to the recommended

inflation pressure for the vehicle and the prevailing ambient temperature but

the deviation value continues to show up, the tire is exhibiting a slow leak.

Take appropriate steps to have the tire inspected for any damage or leaks.

7.2.2 Q: Pressure readings at a tire location do not change on the

gauge when air is added, or removed, to correct tire pressure, and a

new transmission has been received.

A: Wheel assemblies may have been relocated/rotated on the trailer without

the SmarTire Trailer-Link

™

ECU having been updated. To correct this, follow

the steps in Section C, 4.2.3 in combination with the SmarTire

®

TPMS

Maintenance Hand tool to relearn sensors into their correct tire positions.

7.3 Diagnosing A Defective, Missing, Or Misplaced Sensor

In the event that a tire sensor does not report to the display after having

gone through the steps above, the following sensor checks should also be

performed:

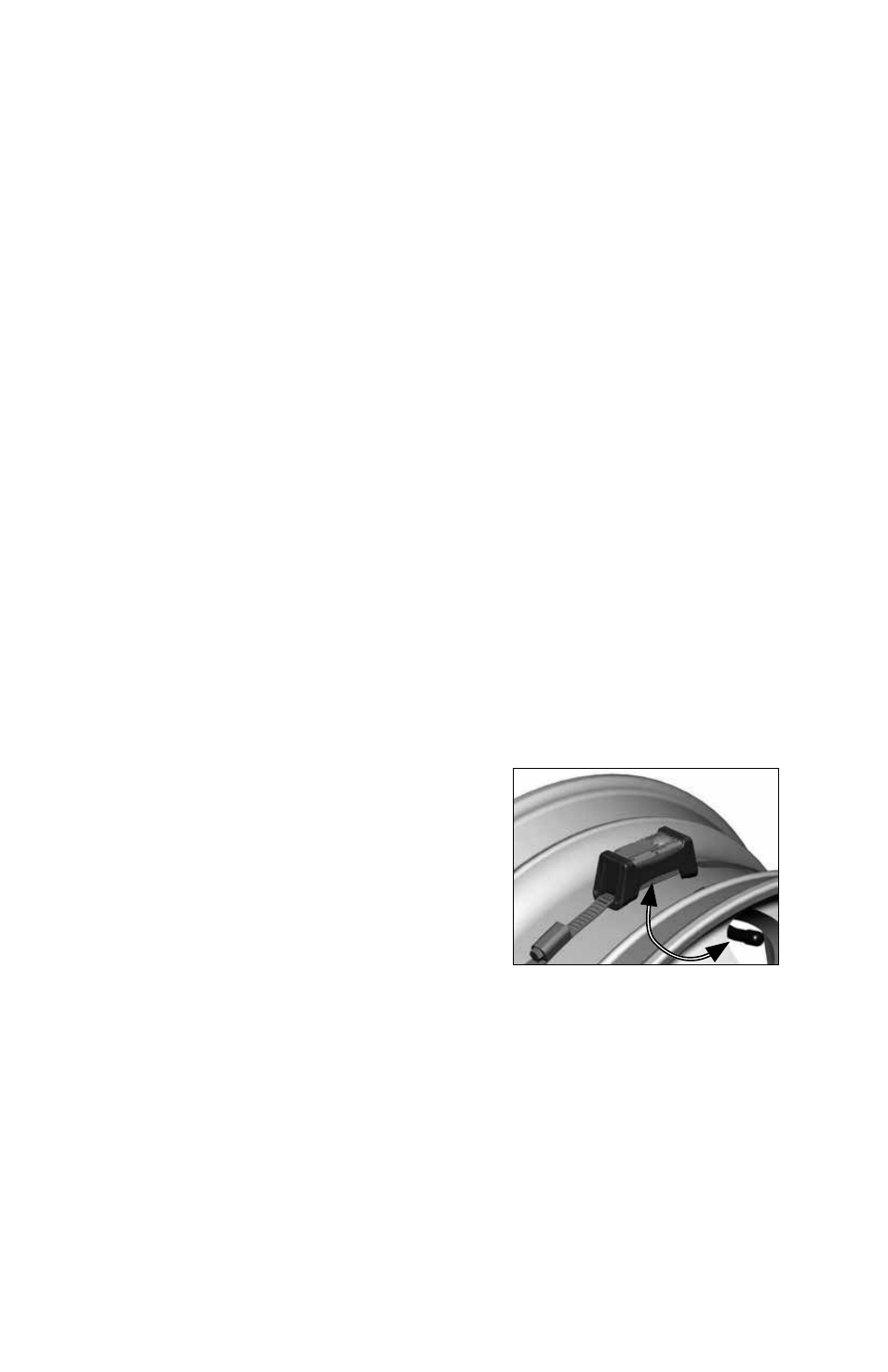

a. Try to initiate the sensor opposite of

the valve stem. There are times when

the tire installer accidentally places the

sensor 180 degrees opposite of the

valve by misreading the instructions

(sensors are required to be placed 180

degrees opposite of each other for dual

wheel assemblies). Check for new data

on the gauge for the affected wheel

position.

Figure 47

b. If step a. was unsuccessful, try to initiate the sensor at the bottom of the

wheel, no matter where the valve stem is located. If this attempt updated

the display screen, rotate the wheel 180 degrees forward and initiate the

sensor again at the BOTTOM of the wheel. If the second initiation also

provided new data (cycle power between tries to empty the screen, not

necessary when using SmarTire Maintenance Hand tool), it is evidence

of a broken cradle and/or strap. The sensor is simply falling to the lowest

point in the wheel after each rotation. Remove the tire and replace the

cradle and strap. Depending on the damage done to the sensor itself,