Ec-30, Controller hardware configurations, Controller with plc – Bendix Commercial Vehicle Systems EC-30 ABS/ATC CONTROLLER 2/08 User Manual

Page 3

3

EC-30

™

CONTROLLER HARDWARE

CONFIGURATIONS

The EC-30

™

controller ABS ECU is available in different

hardware confi gurations in order to support various ABS,

ATC and power line carrier (PLC) features. See chart 3.

EC-30

™

controller premium PLC hardware can be

confi gured for four or six sensors, with or without ATC, and

PLC can be disabled.

EC-30

™

controller basic models can not be confi gured for

six sensors or ATC.

PLC hardware is needed to support PLC communication.

Always verify that you are working with the correct EC-30

™

controller by referring to the part number label on the ECU.

EC-30

™

CONTROLLER WITH PLC

Effective March 1, 2001, all towing vehicles must control

an in-cab trailer ABS warning lamp. Trailers built after this

date will transmit the status of the trailer ABS unit over the

power line (blue wire of the J560 connector) to the tractor

using PLC communications.

The PLC signal is usually broadcasted by the trailer ABS

ECU. The application of PLC technology for the heavy vehicle

industry is known as PLC4Trucks. The Bendix

®

EC-30

™

controller premium with PLC, and basic with PLC, will support

PLC communication in accordance with SAE J2497.

Identifying an EC-30

™

Controller with PLC

An EC-30

™

controller with or without PLC can be identifi ed

by the individual part number label on the ECU. Also, an

EC-30

™

controller may have one of the following labels

applied:

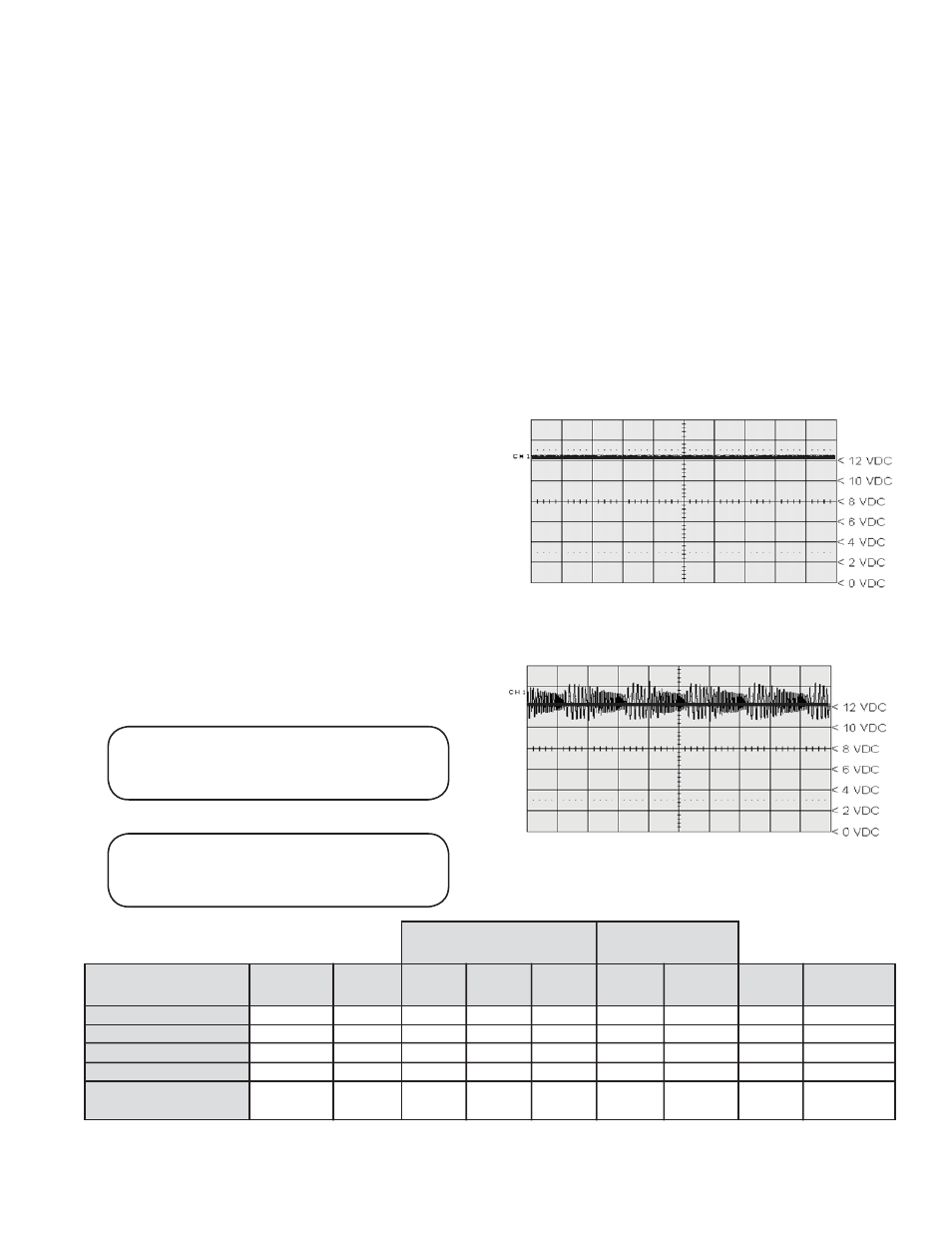

Measuring / Identifying the PLC Signal

An oscilloscope can be used to verify the presence of a PLC

signal on the power line. The PLC signal is an amplitude

and frequency modulated signal. Depending on the fi ltering

and load on the power line, the PLC signal amplitude can

range from 5.0 mVp-p to 7.0 Vp-p. Suggested oscilloscope

settings are (AC coupling, 1 volt/div, 100 µsec/div). The

signal should be measured at the power leads of the

EC-30

™

controller. See fi gures 3 & 4.

The EC-30

™

controller will not broadcast PLC messages

unless it is specially programmed to do so. With this

standard confi guration, an ABS trailer equipped with PLC or

a PLC diagnostic tool will need to be attached to the vehicle

in order to generate a PLC signal on the power line.

1

Required for all towing vehicles built after March 1, 2001.

CHART 3 - EC-30

™

CONTROLLER HARDWARE CONFIGURATIONS

FIGURE 3 - POWER LINE WITHOUT PLC SIGNAL

FIGURE 4 - POWER LINE WITH PLC SIGNAL

EC-30 Hardware

Sensors

ATC

J1587

J1939

Blink

J1922

J1939

PLC

Trailer

Confi gurations

Codes

ABS WL

1

Basic

4

X

X

X

X

Premium 4,

6

X

X

X

X

X

Basic PLC 4

X

X

X

X

X X

Premium PLC

4, 6

X

X

X

X

X

X

X

EC-17/EC-16 Service 4,

6

X

X

X

X

X

X

Replacement

Diagnostics

Engine

Communication

ECU supports IN-CAB

Trailer ABS warning lamp.

White Label:

Orange Label:

ECU does not support an in-cab

Trailer ABS warning lamp.