Bryant 4-Way Multipoise Fixed-Capacity Direct-Vent Condensing Gas 350MAV User Manual

Page 9

1. Turn off electrical supply to furnace.

2. Remove main furnace door.

3. Disconnect cap from unused drain tap on inducer housing.

(See Fig. 14.)

4. Connect field-supplied 1/2-in. I.D. tube to upper inducer

housing drain connection.

5. Insert funnel in drain tube and pour up to 1 quart antifreeze,

propylene glycol (RV, swimming pool antifreeze, or

equivalent) into funnel until it is visible at point where

condensate enters open drain. (See Fig. 15.)

6. Reconnect drain cap to inducer housing.

7. Replace main furnace door.

CAUTION:

Do not use ethylene glycol (Prestone II

antifreeze/coolant or equivalent automotive type). Failure

of plastic components will occur.

8. Propylene glycol need not be removed before restarting

furnace.

WIRING DIAGRAM

See Fig. 16 for Wiring Diagram.

TROUBLESHOOTING

Use the Troubleshooting Guide, the status code LED on the

cotntrol and the Component Test to isolate furnace operation

problems.

A.

Status Codes

For an explanation of status codes, refer to service label located on

back of main furnace door or Fig. 17 and the Troubleshooting

Guide. The stored status codes will NOT be erased from the

control memory if 115- or 24-v power in interrupted. The control

will store up to 7 Status Codes.

NOTE:

Removing the blower access door will open the blower

access door switch and terminate 115-v power to the control.

To read current status code, remove main furnace door. The status

code LED can be viewed through the sight glass on the blower

access door.

NOTE:

NO thermostat signals may be present at control and all

blower off delays must be completed to view previous codes.

To retrieve previous codes, remove 1 of the red main limit or flame

rollout switch wires for 1 to 4 sec until the LED light goes out, then

reconnect it. (Do not leave red wire disconnected for longer

periods of time as the control will assume an overtemperature

condition exists and will respond with blower operation.) This

places the control in the status recall mode and displays the first

code stored in memory.

Record the code and repeat the disconnect and reconnect of the red

wire, recording each code until code 11 is displayed indicating no

addition codes. After the last code is displayed or after 2 minutes

in the code recall mode the control will return to normal standby

mode.

B.

Component Test

WARNING:

Blower access panel door switch opens

115-v power to control center. No component operation

can occur. Caution must be taken when manually closing

this switch for service purposes. Failure to follow this

warning could result in electrical shock, personal injury,

or death.

Use the Component Test to check furnace components for proper

operation. To initiate the component self-test sequence, shut off

the room thermostat or disconnect the

″

R

″

thermostat lead. Briefly

(approximately 2 sec) short the TWIN/TEST terminal to the C

OM

24V terminal. The status LED will turn off. The test sequence will

be as follows:

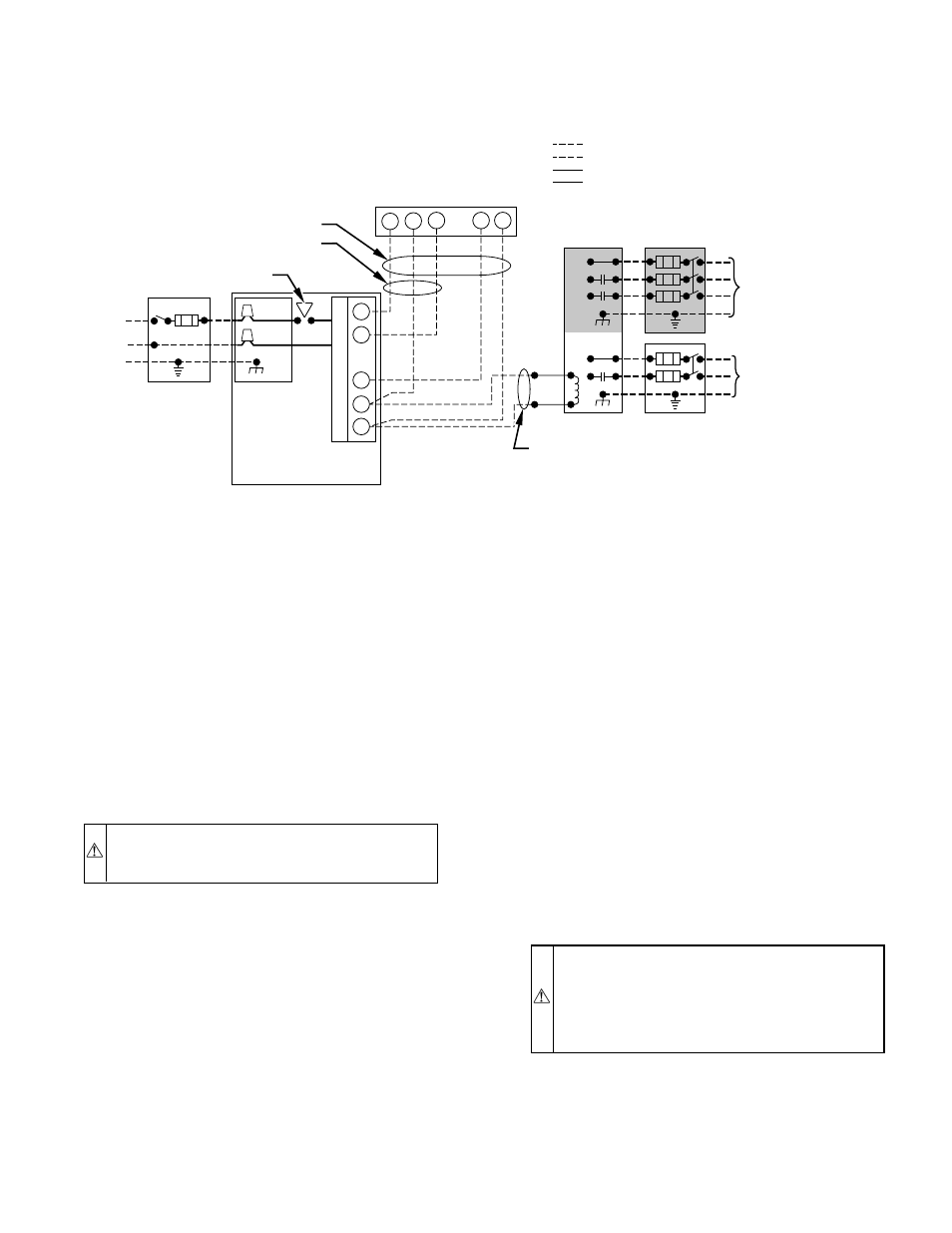

Fig. 11—Field Wiring

A99440

115-V FIELD-

SUPPLIED

DISCONNECT

AUXILIARY

J-BOX

24-V

TERMINAL

BLOCK

THREE-WIRE

HEATING-ONLY

FIVE WIRE

NOTE 1

NOTE 2

FIELD-SUPPLIED

DISCONNECT

CONDENSING

UNIT

TWO

WIRE

FURNACE

C

O

N

T

R

O

L

R

G

COM

W

C

R

G

Y

GND

GND

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-V WIRING

208/230- OR

460-V

THREE

PHASE

208/230-V

SINGLE

PHASE

BLOWER DOOR SWITCH

WHT

BLK

WHT

BLK

NOTES:

Connect Y-terminal in furnace as shown for proper blower operation.

Some thermostats require a "C" terminal connection as shown.

If any of the original wire, as supplied, must be replaced, use

same type or equivalent wire.

W

Y/Y2

GND

THERMOSTAT

TERMINALS

1.

2.

3.

—9—