Bryant 4-Way Multipoise Fixed-Capacity Direct-Vent Condensing Gas 350MAV User Manual

Page 3

WARNING:

Turn off the gas and electrical supplies to

the unit before performing any maintenance or service.

Follow the operating instructions on the label attached to

the furnace. Failure to follow this warning could result in

personal injury or death.

The minimum maintenance that should be performed on this

equipment is as follows:

1. Check and clean or replace air filter each month as needed.

2. Check blower motor and wheel for cleanliness annually.

3. Check electrical connections for tightness and controls for

proper operation each heating season. Service as necessary.

4. Check for proper condensate drainage. Clean as necessary.

5. Check for blockages in combustion-air and vent pipes

annually.

6. Check burners for cleanliness annually.

CAUTION:

Personal injury could result from sharp

metal edges, etc. Use care and wear protective clothing

safety glasses, and gloves when removing parts.

I.

CLEANING AND/OR REPLACING AIR FILTER

The air filter arrangement may vary depending on the application

or orientation. Filter could be located in furnace blower compart-

ment or in filter cabinet.

WARNING:

Never operate unit without a filter or with

the blower access panel removed. Failure to follow this

warning could result in a fire or personal injury.

CAUTION:

Operating a unit without a filter or with the

blower access door removed could cause damage to the

furnace blower motor. Dust and lint on internal parts of

furnace can cause a loss of efficiency.

NOTE:

If the filter has an airflow direction arrow, the arrow must

point toward the blower.

To clean or replace filters, proceed as follows:

If filter is installed in filter cabinet adjacent to furnace:

1. Turn off electrical supply to furnace.

2. Remove filter cabinet door.

3. Slide filter out of cabinet.

4. If equipped with permanent, washable filter, clean filter by

spraying cold tap water through filter in opposite direction

of airflow. Rinse filter and let dry. Oiling or coating of the

filter is not recommended.

5. If equipped with factory specified disposable media filter,

replace only with a factory-authorized media filter of the

same size.

6. Slide filter into cabinet.

7. Replace filter cabinet door.

8. Turn on electrical supply to furnace.

If filter is installed in furnace blower compartment:

1. Turn off electrical supply to furnace.

2. Remove main furnace door and blower access panel.

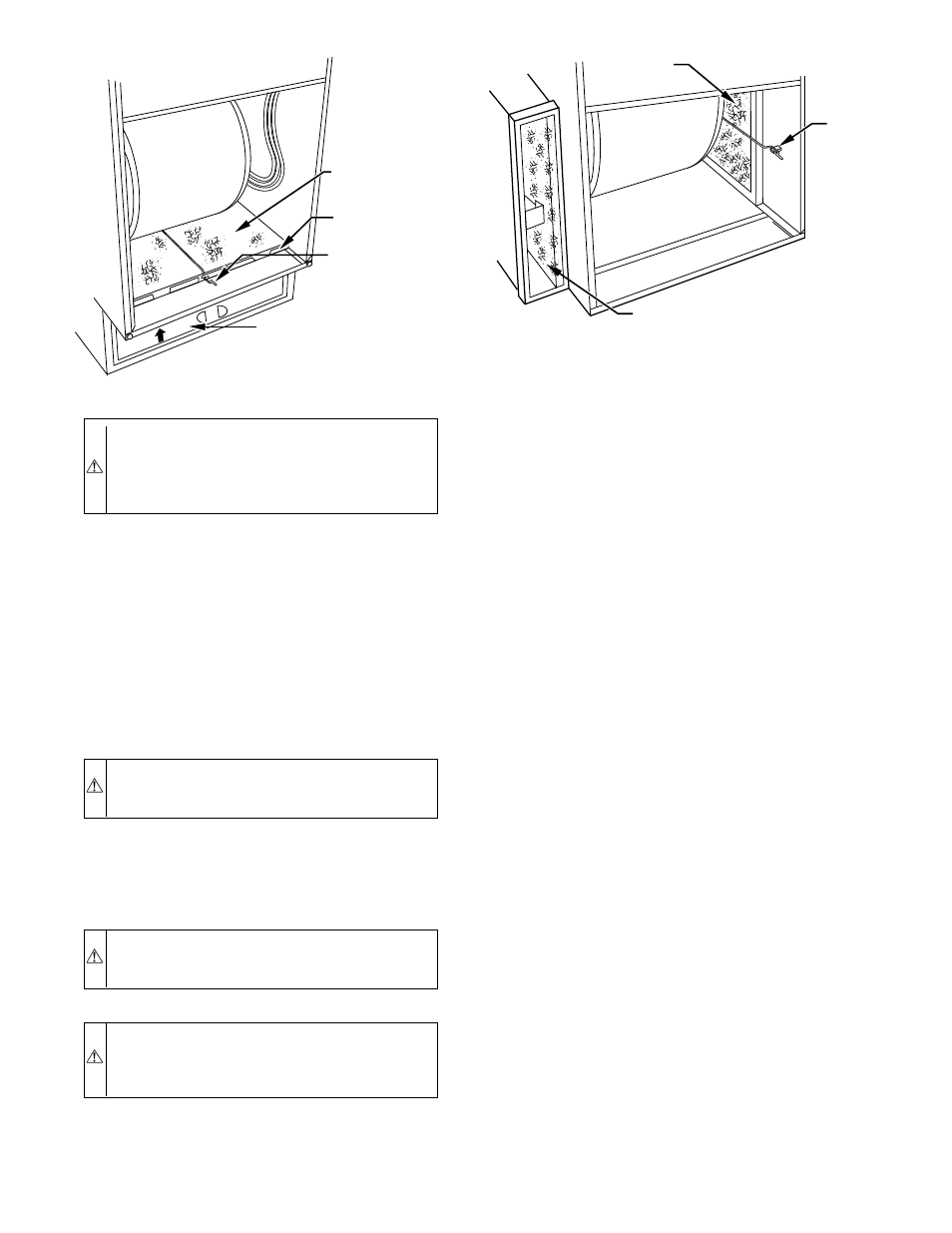

3. Release filter retainer wire. (See Figs. 3 or 4.)

4. Slide filter out of furnace.

5. Furnaces are equipped with permanent, washable filter(s).

Clean filter by spraying cold tap water through filter in

opposite direction of airflow.

6. Rinse filter and let dry. Oiling or coating filter is not

recommended.

7. Slide filter into furnace.

8. Recapture filter retainer wire.

9. Replace blower access panel and main furnace door.

10. Turn on electrical supply to furnace.

II.

BLOWER MOTOR AND WHEEL MAINTENANCE

To ensure long life, economy, and high efficiency, clean accumu-

lated dirt and grease from blower wheel and motor annually.

The inducer and blower motors are pre-lubricated and require no

additional lubrication. These motors can be identified by the

absence of oil ports on each end of the motor.

The following items should be performed by a qualified service

technician.

Clean blower motor and wheel as follows:

WASHABLE

FILTER

FILTER

SUPPORT

FILTER

RETAINER

WASHABLE FILTER OR

DISPOSABLE MEDIA FILTER

IN FILTER CABINET

A00232

Fig. 3—Bottom Filter Arrangement

FILTER

RETAINER

WASHABLE

FILTER

IN FURNACE

WASHABLE FILTER OR

DISPOSABLE MEDIA

FILTER IN FILTER CABINET

A00233

Fig. 4—Filter Installed for Side Inlet

—3—