Rockwell Automation MaxPak Plus Regenerative Incoming Line CB Kit 23C301-304 User Manual

Page 2

2

1. DISCONNECT AND LOCK OUT ALL INCOMING

DRIVE POWER TO THE MAXPAK PLUS CONĆ

TROLLER.

2. Remove incoming line power connections from the

L1, L2 and L3 (181, 182 and 183) terminals of the

power unit. Mark the wires with L1, L2 and L3 identiĆ

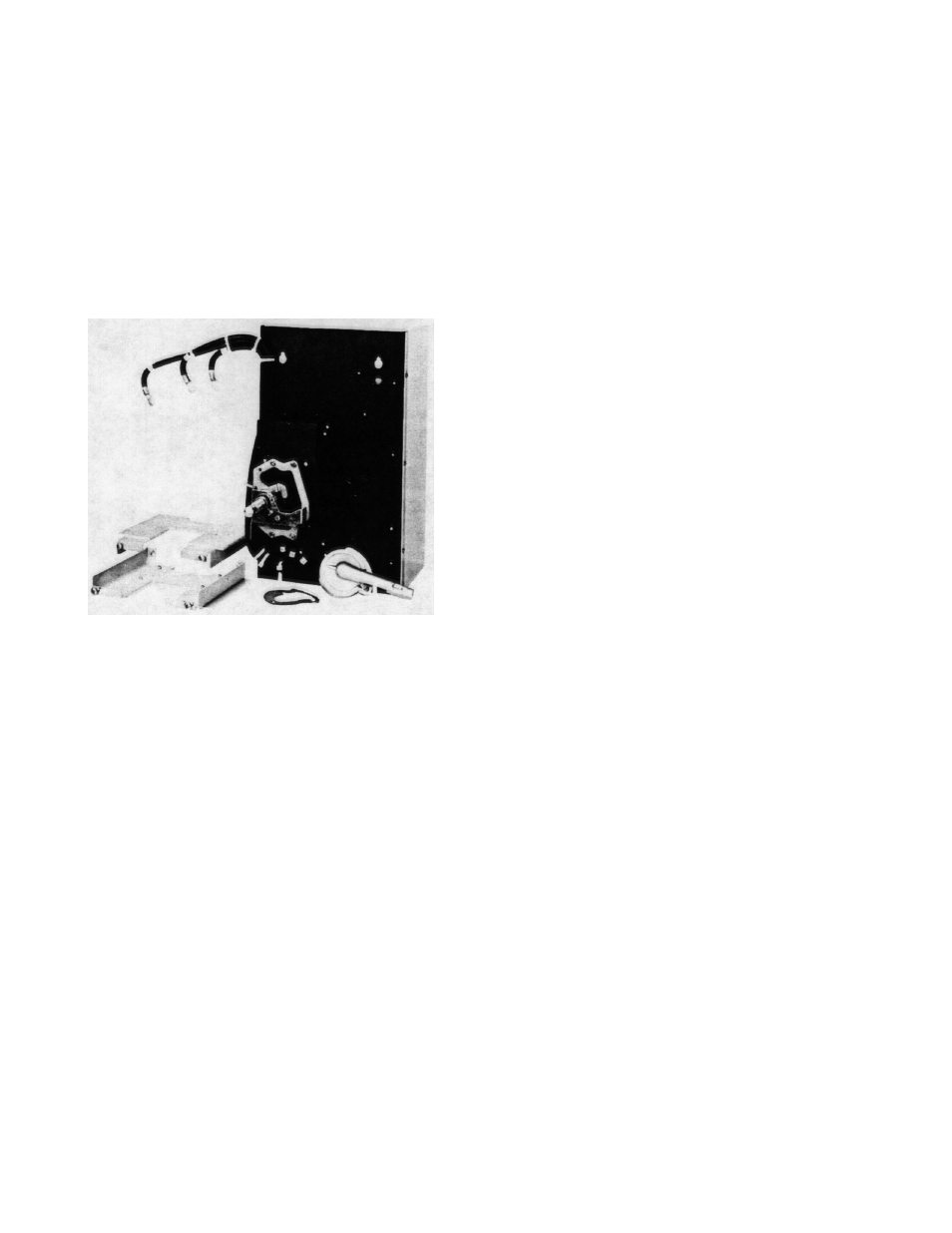

fication as they are being removed. This is essential

to allow reconnection of line power in step 15 with

the same phase rotation. Failure to do so will reĆ

sult in a failure of the drive to run when reenerĆ

gized in step 17.

NOTE: It the controller has already been equipped

with a contactor cover kit, Model number 23C310,

Steps 3 through 7 below may be skipped.

Top and bottom mounting brackets installed as

part of the contactor cover kit will be used to support

the circuit breaker and its mounting panel. Proceed

to step 8.

3. It is first necessary to remove the bus bar support

noted as <10 on sheet 2 of the assembly drawing.

Discard the support once removed.

4. Locate the top mounting bracket and remove the

bus bar support which is fastened to it with two PhilĆ

lips head screws. The bus bar support will be reinĆ

stalled onto the top mounting bracket using these

screws in a later step. See note <9 on sheet 2 of the

assembly drawing.

NOTE: A long (12 inch or longer) #2 Phillips

head screwdriver with a magnetic tip is required

to install the screws in steps 5 and 7 below. It a

magnetic tipped Phillips head screwdriver of

this length is not available, putty, masking tape,

or some other means should be used to hold the

screws on the tip of the screwdriver during

installation. Otherwise, they may drop into the

components on the auxiliary panel from where

they might be difficult to remove and where they

can pose a short circuit risk.

5. Using the 12 inch long Phillips head screwdriver

with #2 magnetic tip, install the top mounting

bracket to the auxiliary panel using two 1/4Ć20 X 1/2

self tapping screws.

6. Remount the busbar support to the top mounting

bracket using the screws removed in step 4 above.

7. If necessary, remove the wire harness base which

dresses the auxiliary contact cable to the auxiliary

panel. This base may occupy one of the two mountĆ

ing holes for the lower bracket. Mount the bottom

mounting bracket using two 1/4Ć20 x 1/2" self tapĆ

ping screws and the magnetic screwdriver. Once

the lower bracket is in place, the auxiliary harness

should be secured to the lower bracket using the tyĆ

rap and base supplied with the kit. If any wires from

the auxiliary harness were disconnected to allow

easier installation of the bottom bracket, they

should be reconnected at this time.

8. Warning: Mount the insulating side shield to the

right side lip of the cover plate using three #6Ć32

x 3/8" self tapping screws. This shield provides

personnel protection by preventing accidental

contact with otherwise hidden armature circuit

buswork. Its installation is required by N.E.C.

and U.L.

9. Connect the load side cable assembly to the load

side (bottom) circuit breaker terminals and tighten

to 125/140 Ib.Ćin. (1.44/1.6 kg.Ćm.)

10. Fasten the circuit breaker mounting plate to the top

and bottom brackets using four 1/4Ć20 x 1/2" self

tapping screws.

11. Connect the load side cable to controller incoming

terminals 181, 182 and 183 and tighten to 125/140

Ib.Ćin. (1.44/1.6 kg.Ćm.)

12. Remove and discard the small cover plate on the

enclosure door.

13. Close the cabinet door and verify the center of the

locking pin on the C/B operator shaft at 15/32" from

the inner door surface. If not, ad just to 15/32" and

then turn shaft CCW until slot is aligned with set

screw. Tighten set screw.

14. Install the circuit breaker handle to the door with the

gasket and mounting screws provided.

15. Reconnect incoming aĆc plant power to the line side

(top) terminations of the circuit breaker. Connect

the wire previously connected to power unit termiĆ

nal L1 to the left side breaker terminal, the wire from

L2 to the center terminal and the wire previously

connected to power unit terminal L3 connected to

the right side breaker terminal. Failure to follow

this procedure may result in phase rotation reĆ

versal and a failure of the drive to run when reenĆ

ergized in step 17.

16. Verify the circuit breaker magnetic trip units to LO.