Installation – Rockwell Automation FlexPak Plus DB Kit 14C630,-C644, C420-434 User Manual

Page 2

2

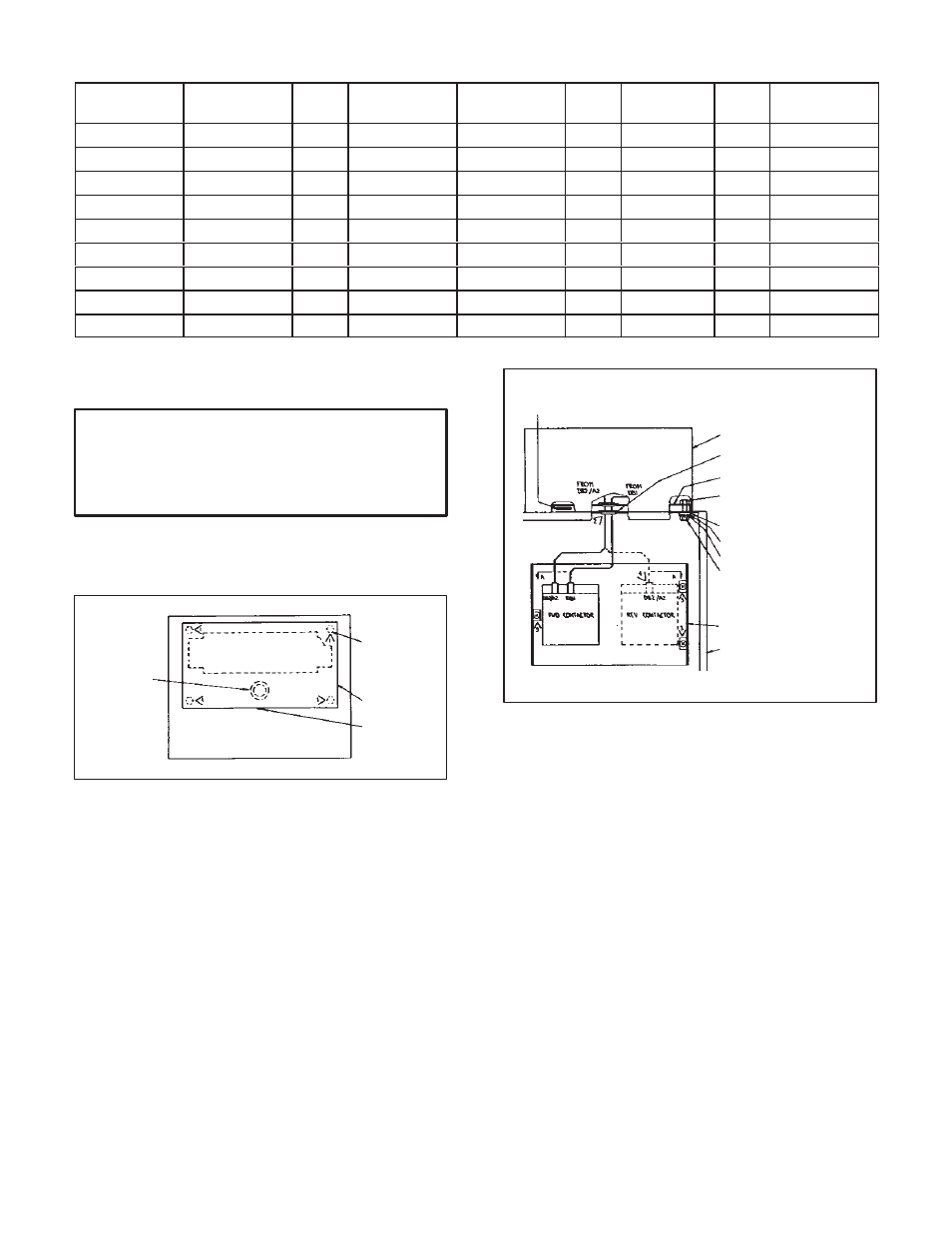

Table 2 - 460VAC, 3 Phase, 50/60 Hz 500VDC Armature

MinPak Plus

Model No.

FlexPak Plus

Model No.

HP

RES Value

(OHMS)

Reliance

Part No.

QUA

Connection

Total

OHMS

WattĆSeconds

@ 375

°

C

14C434

14C644

ă3

20.87ă

48267ĆP

2

Series

41.74ă

ă4,090

14C425

14C635

ă5

12.06ă

48267ĆM

2

Series

24.10ă

ă3,894

14C426

14C636

ă7.5

ă5.930

48267ĆJ

3

Series

17.79ă

11,811

14C427

14C637

10

ă4.698

48267ĆH

3

Series

14.09ă

14,985

14C428

14C638

15

ă3.044

48267ĆF

3

Series

ă9.132

23,763

14C429

14C639

20

ă2.370

48267ĆE

3

Series

ă7.110

30,426

14C430

14C640

25

ă1.912

48267ĆD

3

Series

ă5.736

38,943

14C431

14C641

30

ă1.523

48267ĆC

3

Series

ă4.569

49,065

14C432

14C642

40

ă1.212

48267ĆB

3

Series

ă3.636

62,676

(Note: Initial Current of 150% Derated I

A

)

INSTALLATION

WARNING

BEFORE ATTEMPTING TO INSTALL THIS MINĆ

PAK PLUS/FLEXPAK PLUS MODIFICATIONKIT

DISCONNECT AND LOCK OUT ALL SOURCES

OF INCOMING POWER TO THE CONTROLLER.

MINPAK PLUS:

Remove 5 knockouts in top of cabinet (Figure 3).

KNOCKOUT

KNOCKOUT

DB COVER

TAPTITE

SCREW

Figure 3 - Top View of Three Phase

MinPak Plus Cabinet

1. Insert grommet into 1.75 diameter hole.

2. Place assembled mtg. panel on top of cabinet and

feed leads DB1 and DB2/A2 through the grommet.

3. Secure assembled mounting panel to cabinet usĆ

ing four hex head cap screws, washers, flatwashĆ

ers, split washers and hex nut mounting hardware

(Figure 8). (NOTE: Hardware must be used as

shown in Figure 4 to insure NEMA 12 rating.)

4. Mount DB cover to mounting panel by inserting

tabs into slots on mounting panel and using taptite

screw provided.

MOUNTING TABS

DB COVER

GROMMET

ASSEMBLED MTG.

PANEL

HEX HEAD CAP SCREW

WASHER

FLAT WASHER

SPLIT WASHER

HEX NUT

AUX. CHASSIS WITH

FUSE & CB MTG.

PLATE REMOVED

MINPAK CABINET

WITHOUT DOOR

Figure 4 - Front View of Three Phase

MinPak Plus Cabinet

5. Open cabinet door and open controller face plate

and let hang open.

6. /Remove fuse/circuit breaker mounting plate from

auxiliary chassis by removing three screws.

7. Connect lead DB1 to forward contactor and lead

DB2/A2 to other side of forward contactor. For reĆ

versing applications connect DB2/A2 to reversing

contactor. (Refer to Figures 4 and 5).

8. Remount fuse/circuit breaker plate to auxiliary

chassis using three existing screws.

9. Tighten all connectors that may have loosened durĆ

ing kit installation.

10. Close controller face plate and tighten screws.