1 - product description, Kit contents, Wiring guidelines – Rockwell Automation FlexPak 3000 115 VAC Control Opt. Board M/N 917FK0101 User Manual

Page 6: 0 product description, 1 kit contents, 2 wiring guidelines

1Ć1

1.0 PRODUCT DESCRIPTION

This manual provides instructions for installing the 115 VAC Control Option Board for use with a

FlexPakr 3000 driveor MaxPakr III drive. It is intended for qualified electrical personnel. The

installation procedure consists of mounting the Control Option Board, wiring user control devices to

theboard, and wiring theboard to theexisting control inputs on theFlexPak 3000 drive's regulator

board terminal strip or the MaxPak III drive's control and signal terminals. The source of control

power must be provided by the user.

TheControl Option Board's component layout is shown in figure1.1. A mounting holetemplateis

provided in figure 1.2. Appendices A and B describe circuit operation and provide technical

specifications.

No software configuration or parameter changes are required on the FlexPak 3000 drive. The

MaxPak III drive installation may require configuration and parameter changes on the part of the end

user. Separate installation procedures are provided for FlexPak 3000 drives and MaxPak III drives.

Perform the steps in the order in which they are presented in this manual.

1.1 Kit Contents

The 115 VAC Control Option Board is sold with the necessary connectors and mounting hardware as

kit model number 917FK0101. Table 1.1 provides a parts list for the kit.

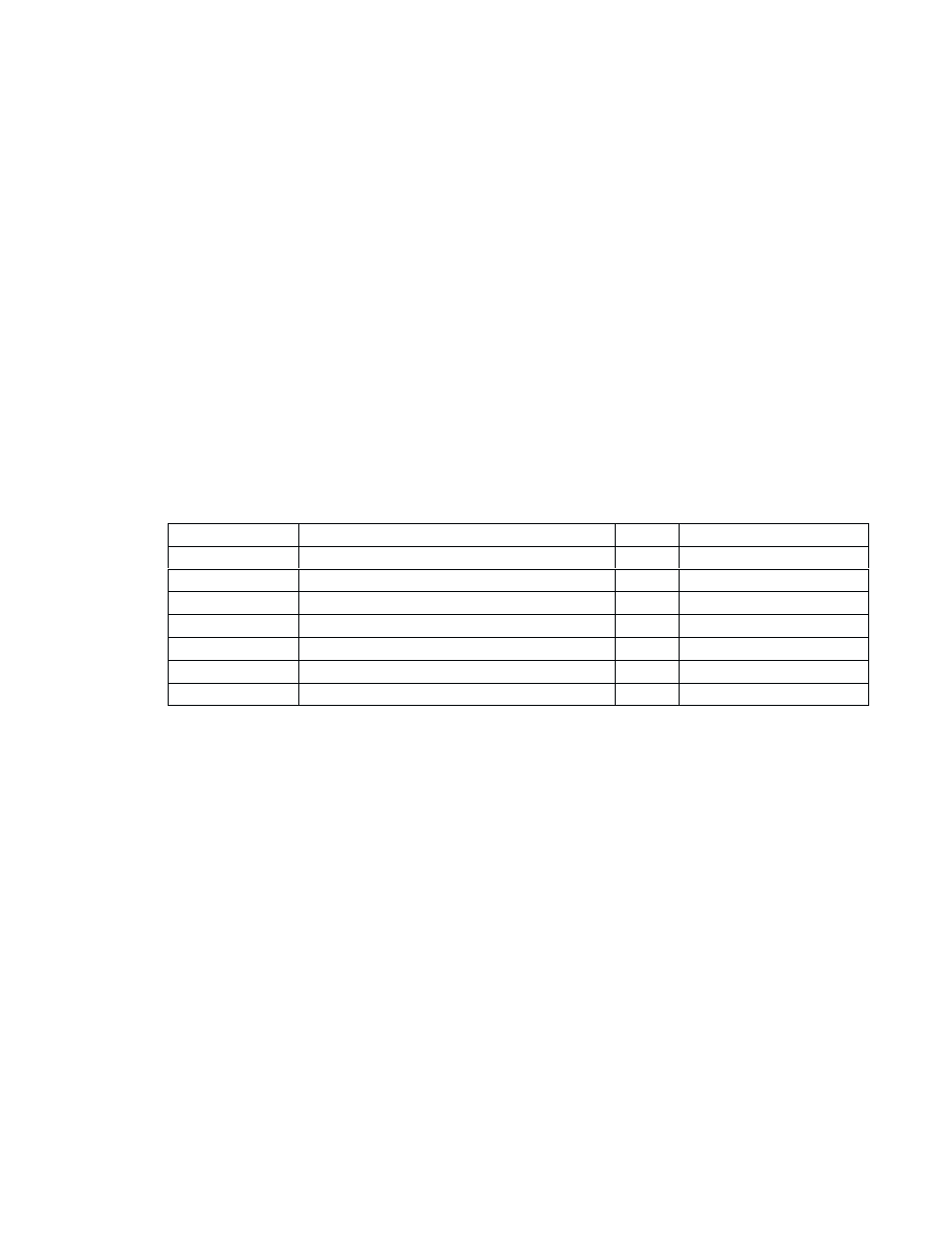

Table1.1 Ć 115 VAC Control Option Board Parts List

Item No.

Description

Qty

Reliance Part Number

1

115 VAC Control Option Board

1

OĆ60053Ć000

2

3ĆPin AĆC SourceInput Connector

1

49455Ć124GC

3

14ĆPin AĆC Input Connector

1

49455Ć124GP

4

CableAssembly

1

707973Ć13R

5

M4 x 30 TaptiteScrew

4

419062Ć100PGN

6

M4 Flat Washer

4

419064Ć1SG

7

Label: Danger

1

610293Ć201A

1.2 Wiring Guidelines

It is the user's responsibility, and the responsibility of the installing electrical contractor, to ensure that

this equipment is installed properly according to this manual and in conformance with all applicable

codes. The primary code covering the installation of motors, drives, operator devices, controls, and

other related equipment is NFPA 70 "National Electrical Code," published by the National Fire

Protection Association. The local inspecting agency should be consulted for information about any

other local, national, or international codes that may also apply.

Wiring Levels and Classes

Drive systems include a wide variety of electrical and electronic circuits. These range from power

circuits that radiate considerable electromagnetic energy to sensitive electronic circuits susceptible to

induced voltages or currents. System wiring is divided into the following four basic levels, depending

upon each circuit's susceptibility to noise or its noiseĆgenerating capability.

Level 1: (High Susceptibility) Ć Low Level Signal Circuits

Analog signals less than 50 V and digital signals less than 15 V.

Level 2: (Medium Susceptibility) Ć Medium Level Signal Circuits

Analog signals greater than 50V, switching signals less than 50 V.

Level 3: (Low Susceptibility) Ć Control Circuits

Switching signals greater than 50 V, analog signals greater than 50 V, regulating signals of

50 V with currents less than 20 A, and AĆC feeders 20 A or less.