Power module replacement – Rockwell Automation 20D Power Module/SCR Replacement - Frame 6 User Manual

Page 3

3

D. Re-assemble in reverse order. Tighten cable screws to

4.0

±1.0 N-m (35 ±9.0 lbf.-in.).

E. If no further replacement is needed, re-assemble drive.

Tighten sheet metal screws to 3.2 N-m (28 lbf.-in.).

Power Module Replacement

Refer to

for component locations.

A. If the right-side sheet metal enclosure has not been

removed, go to page 1, Step

G.

B. Remove the left-side sheet metal enclosure by taking

out the appropriate screws.

C. Remove the Power Supply Board mounted on the back

panel of the drive.

D. If the drive has the Dynamic Braking Option installed,

disconnect the two bus bars, cable and two flex cables.

E. Remove the U, V and W cables that extend through the

Current Transducers. Remove the Terminal Spacers.

F. Disconnect the J1, J2 & J3 wire assemblies.

G. Loosen the heatsink assembly by removing; two

heatsink bracket screws, one gusset screw and four

heatsink screws. Position the assembly to gain access

to the Power Module.

H. Remove the Plastic Clamp by taking out the two

screws.

I. Remove the Power Module Bus Bar and three Snubber

Capacitors by taking out the six screws.

J. Remove the eight screws securing the Power Module.

Remove Module.

K. Thoroughly clean the module mounting surface. Apply

a thin coating of the supplied thermal grease to the

new module. Install with the supplied screws and

tighten using the sequence below.

L. Re-assemble in reverse order.

M. Tighten sheet metal screws to 3.2 N-m (28 lbf.-in.).

Brake IGBT Torque Sequence

1

4

3

2

First Sequence: 0.7

±0.2 N-m (6.0 ±2.0 lbf.-in.)

Second Sequence: 1.6

±0.4 N-m (14 ±4.0 lbf.-in.)

Final Sequence: 5.2

±0.8 N-m (46 ±7.0 lbf.-in.)

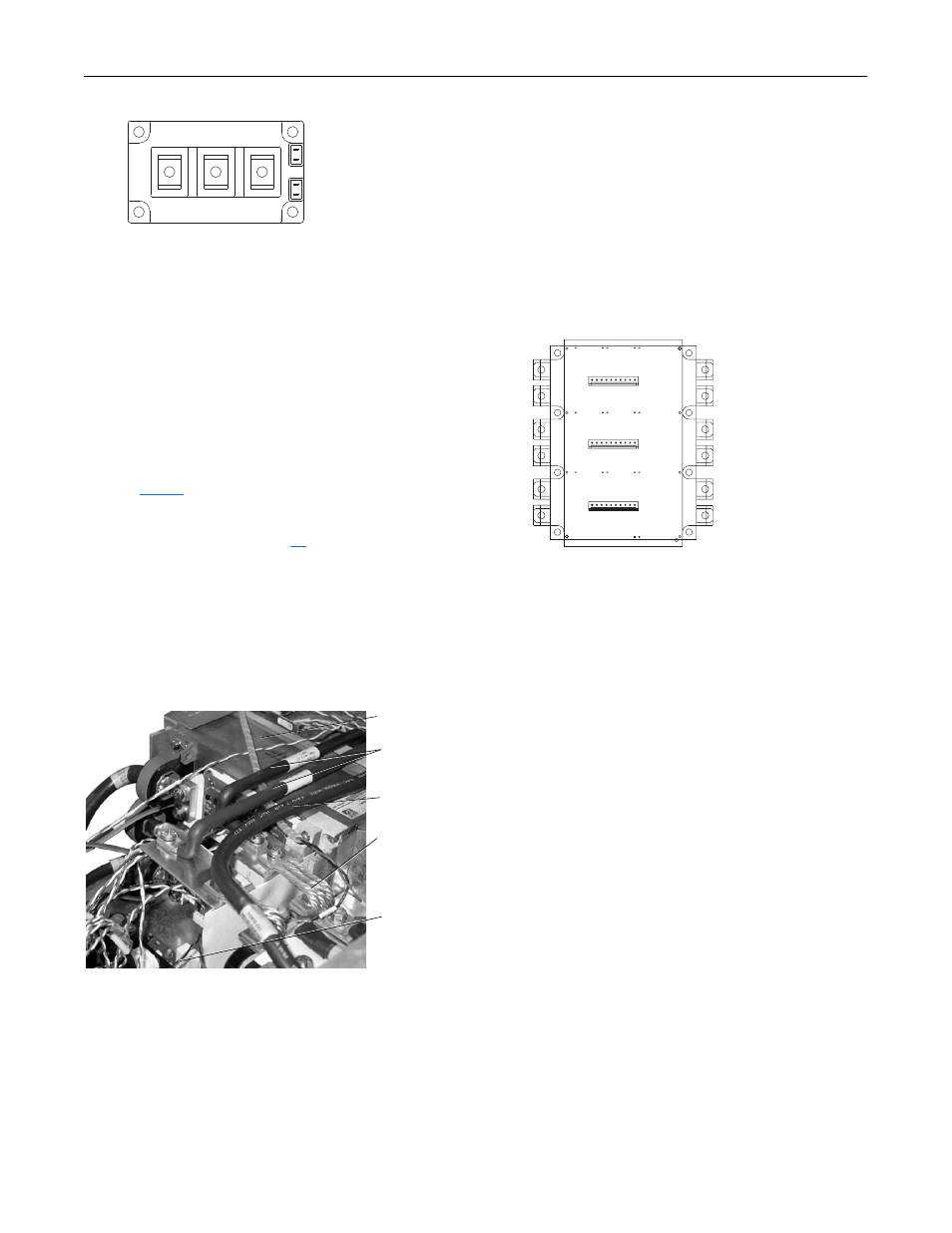

Brake Bus

Bars

Brake Cable

Flex Cables

Power

Supply

Board

Heatsink

Power Module Torque Sequence

5

8

3

2

1

4

7

6

First Sequence: 0.7

±0.2 N-m (6.0 ±2.0 lbf.-in.)

Second Sequence: 1.6

±0.4 N-m (14 ±4.0 lbf.-in.)

Final Sequence: 5.2

±0.8 N-m (46 ±7.0 lbf.-in.)