Rockwell Automation 8510 Hi-Res Feedback Instructions User Manual

Page 7

High Resolution Magnetic Feedback

Instructions

7

Table B

Mounting Dimensions (in millimeters)

Detecting Gear

Catalog Num-

ber

8510SA-PG225

8510SA-PG226

8510SA-PG300

8510SA-PG400

8510SA-PG500

8510SA-

PG500P

Num-

ber of

Teeth

225

256

300

400

500

500

Stan-

dard

52h5

65h5

85h5

120h5

150h5

150h5

0.0 / –0.01

3

0.0 / –0.01

3

0.0 / –0.01

5

0.0 / –0.01

5

0.0 / –0.01

8

0.0 / –0.01

8

Precision

52

65

85

120

150

150

Mounting

Flange Max.

O.D.

82

92

112

152

192

192

Clamping

Ring

Max. O.D.

82

92

112

152

192

192

Clamping

Ring

I.D.

52

65

85

120

150

150

+0.05 / 0.

0

+0.05 / 0.

0

+0.05 / 0.

0

+0.05 / 0.

0

+0.05 / 0.

0

+0.05 / 0.

0

–0.05 / –0.1

0

–0.05 / –0.1

0

–0.05 / –0.1

0

–0.05 / –0.1

0

–0.05 / –0.1

0

–0.05 / –0.1

0

Centering Shaft

O.D.

F

G

H

E

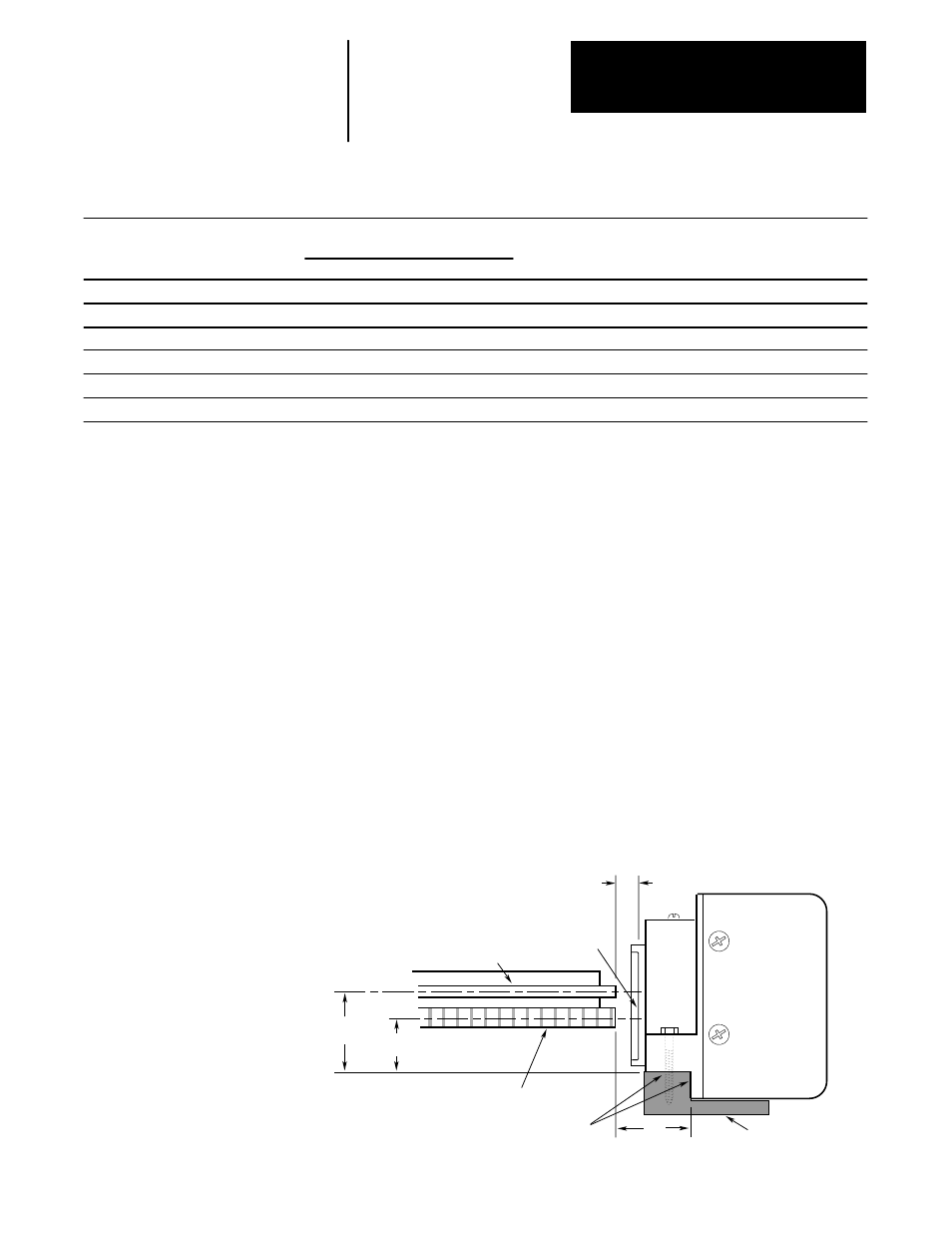

Sensing Head Mounting Requirements

The Sensing Head must be mounted relative to the Detecting Gear as

shown in Figure 4. For proper operation, it is critical that the center line of

the gears be positioned as shown relative to the mounting surface of the

sensor. The air gap between the Detecting Gear surface and the surface of

the circular sensing plate on the Sensing Head must be 0.15

±

0.05 mm. A

properly designed mounting support will permit sufficient adjustment to

assure proper alignment and will be rigid enough to prevent sensor

movement relative to the gear.

Sensing Head Wiring To 8510 AC Spindle Drive

Refer to Chapter 8 in the 8510 AC Spindle Drive System User Manual

(publication 8510-5.1) for wiring details.

Figure 4

Sensing Head Mounting and Alignment (in millimeters)

16.5 ±0.5

9 ±0.5

11

For Z Phase

Gear for A/B Phases

Sensor Face

to Gear Air Gap

0.15 ±0.05

Sensor Face

Mounting Bracket

Mounting Surfaces