Rockwell Automation 1195C-N3_4_5_6 200A / 400A / 600A Vacuum Contactor Auxiliary Contact Replacement User Manual

Page 2

42052-096

G. Ushakow

N/A

N/A

N/A

42052

1006490

1

INSTRUCTION SHEET

BULLETIN 1102C 200A/400A/600A VACUUM CONTACTOR

AUXILIARY CONTACT REPLACEMENT

2-24-04

Mark Jutz

2-24-04

D. Josef

2-24-04

2

4

REVISION

AUTHORIZATION

DIMENSIONS APPLY BEFORE

SURFACE TREATMENT

H

A

B

C

D

E

F

G

(DIMENSIONS IN INCHES)

TOLERANCES UNLESS

OTHERWISE SPECIFIED

REFERENCE

SHEET

OF

DWG.

B

DR.

CHKD.

APPD.

DATE

DATE

DATE

±

±

±

ANGLES:

.XXX:

.XX:

THIS DRAWING IS THE PROPERTY OF

THE ALLEN-BRADLEY CO. INC.

AND MAY NOT BE COPIED, USED OR

DISCLOSED FOR ANY PURPOSE EXCEPT

AS AUTHORIZED IN WRITING BY

THE ALLEN-BRADLEY CO. INC.

LOCATION : MILWAUKEE,

WISCONSIN

U.S.A.

SIZE

1

2

3

4

5

6

7

8

E - DOC

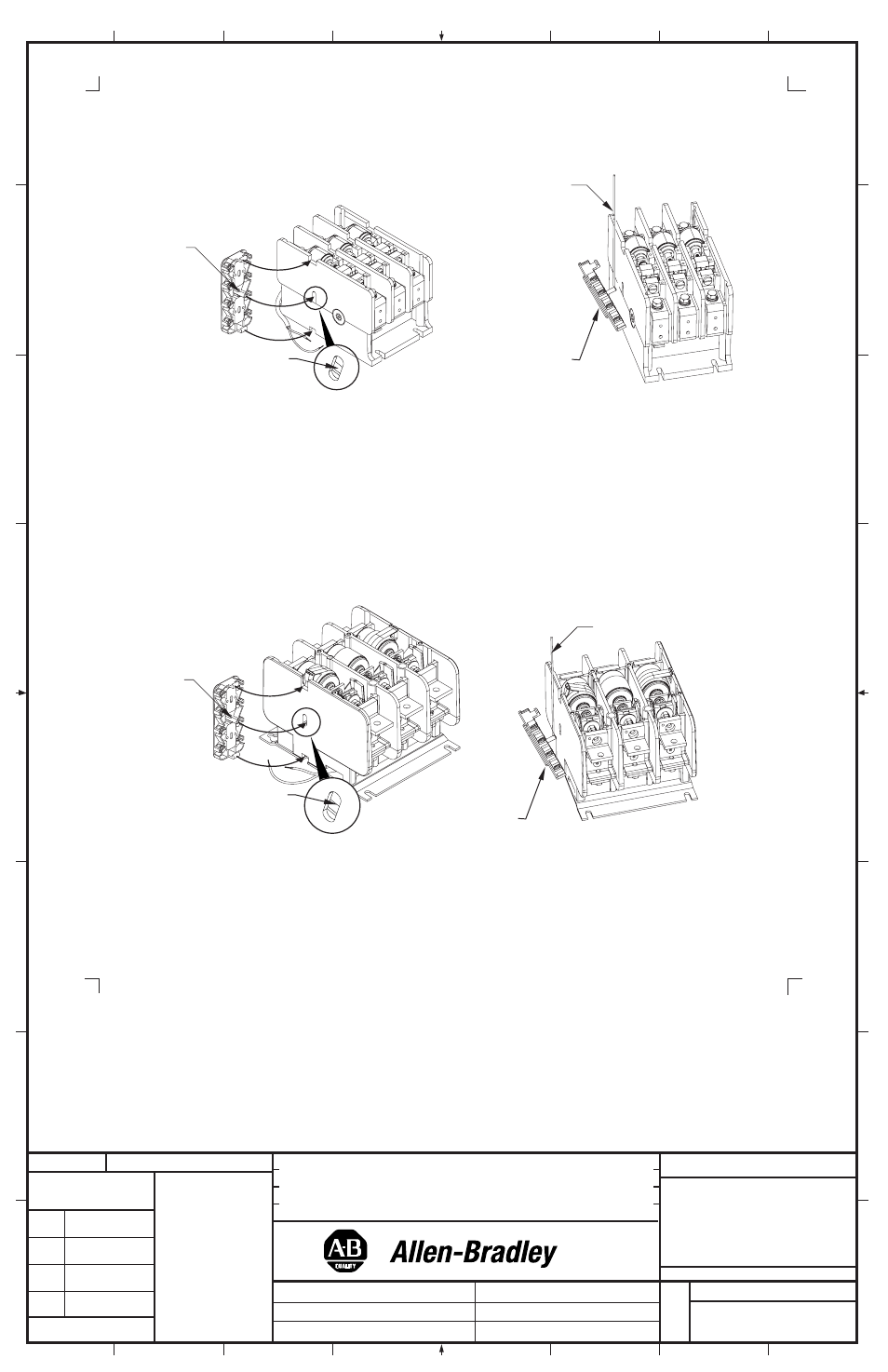

Auxiliary Contact

Installation (400A and 600A)

1. Rotate the Retainer upwards.

2. Insert the lower tab into the recess on the side of the contactor base. With proper installation, the Actuator will fit

into the hole in the slot in the side of the contactor housing

(Figure 4A). Using a thin rod or flat blade, lift the Actuator

up as necessary to insert it into the slot mentioned. Rotate the Retainer to its original position, which will slide over

the upper tab

(Figures 4A & 4B).

Auxiliary Contact

Installation (200A)

1. Insert the lower tab into the recess on the side of the contactor base. With proper installation, the Actuator will fit

into the hole in the slot in the side of the contactor housing

(Figure 3A). Using a thin rod or flat blade, lift the Actuator

up as necessary to insert it into the slot mentioned

(Figures 3A & 3B). Rotate the Retainer (if not attached to cover)

to its original position, which will slide over the upper tab.

2. Reinstall the cover and secure it with the original mounting hardware.

NOTE: Cover must fit under metal bracket

on the Control-Pak. Tighten the four screws in a diagonal pattern to 5 lb-inches (Figure 1).

3. Reattach the coil wire leads and any auxiliary control wires to the Auxiliary (tighten to 7 - 9 lb-inches).

4. Reinstall the contactor. Torque mounting screws to 50 - 75 lb-inches.

5. Reconnect the line and load conductors and tighten the main terminal hardware and bolts to 125 - 145 lb-inches.

3. Reinstall the cover and secure it with the original mounting hardware. NOTE: Cover must fit under metal bracket

on the Control-Pak. Tighten the four screws in a diagonal pattern to 5 lb-in. (Figure 1).

4. Reattach the coil wire leads and any auxiliary control wires to the Auxiliary (tighten to 7 - 9 lb-in).

5. Reinstall the contactor. Torque mounting screws to 50 - 75 lb-inches.

6. Reconnect the line and load conductors and tighten the main terminal hardware and bolts to 180 - 210 lb-inches.

Auxiliary

Auxiliary

Thin rod or

flat blade

Thin rod or

flat blade

Actuator

must fit into

slot shown

Figure 3A

Figure 3B

Figure 4A

Figure 4B

Actuator

must fit into

slot shown

Auxiliary

Actuator

Auxiliary

Actuator

(2)