Rockwell Automation 900-TC8 Temperature / Process Controller User Manual

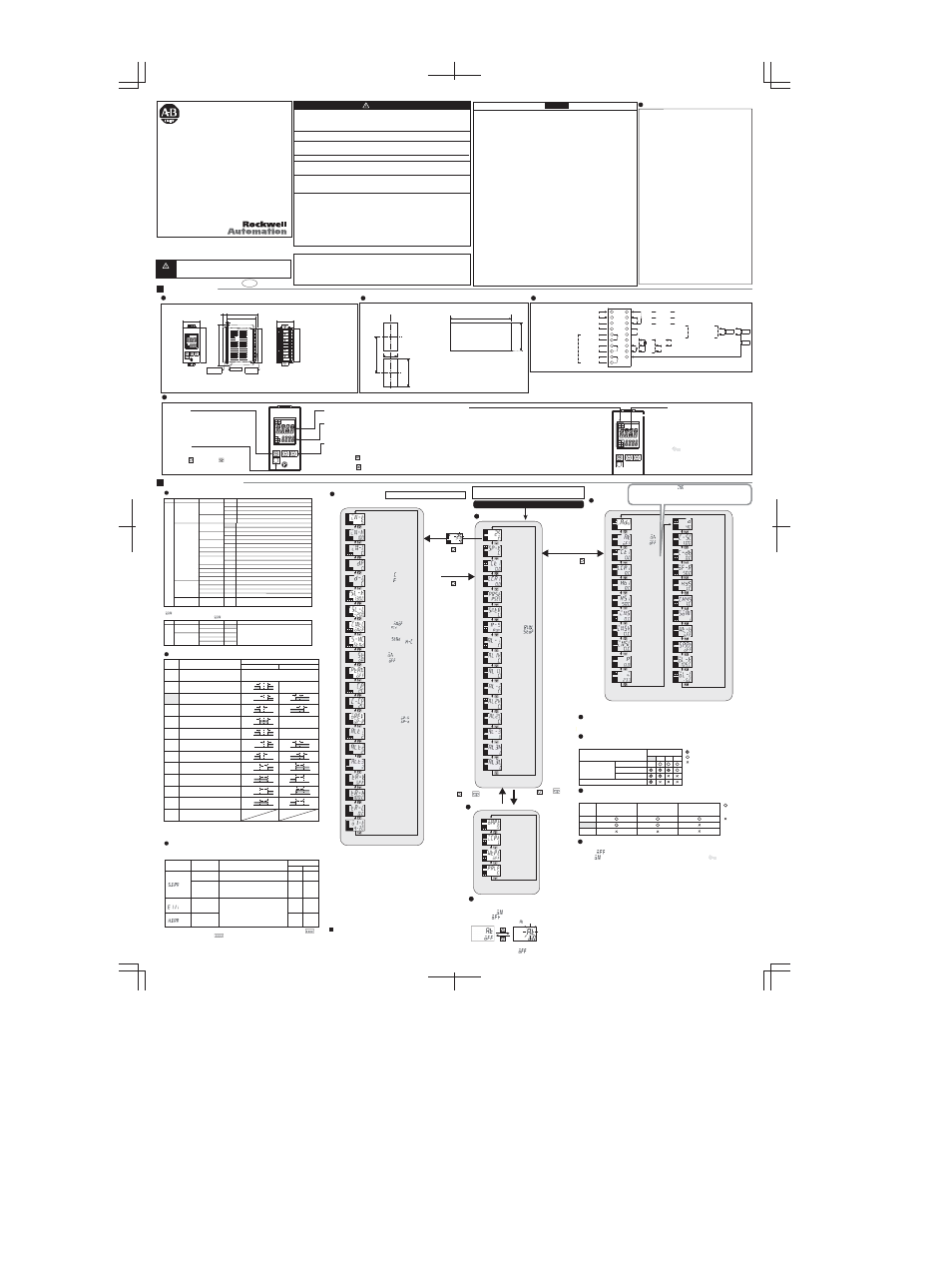

Installation operation menu, Temperature/ process controller

Installation

Operation menu

1618387-8C

Operation / Adjustment protection

The following table shows the relationship between settings and protect limits related to

Operation group and Adjustment group.

Protection function

Protection function is to prevent unwanted settings. It restricts the parameter to be used

or designates if operation of the key is valid or invalid.

Default setting : 0 (shaded)

Operation group

Adjustment group

Process value

Set point

Others

Group

Set value

0

○

◎

◎

◎

1

2

3

Parameter change protection

Parameter changes by key operation are restricted.

OFF “ ”: Parameter can be changed by key operation

ON “ ” : Parameter cannot be changed by key operation (“ ” will light.)

(Protect group parameters can all be changed.)

Initial setting/Communications protection

This protect level restricts movement to the initial setting group,

communications setting group and advanced function setting group.

Alarms

*1:

Upper and lower limits can be set for parameters 1, 4 and 5 to provide

for different types of alarm. These are indicated by the letter "L" and "H".

• Default = "2" (shaded)

Alarm type

1

0

2

3

4

5

6

7

8

9

10

11

12

Vary with "L", "H" values

Vary with "L", "H" values

Vary with "L", "H" values

No alarm function

Output off

Deviation upper/lower limit

standby sequence ON

Absolute value upper limit

Absolute value lower limit

Absolute value upper limit

standby sequence ON

Absolute value lower limit

standby sequence ON

LBA (only for alarm 1)

Deviation lower limit

standby sequence ON

Deviation upper limit

standby sequence ON

Deviation upper/lower range

Deviation upper limit

Deviation upper/lower limit

Deviation lower limit

Alarm output function

Positive alarm value (X)

L H

L H

L H

ON

OFF

SP

Negative alarm value (X)

X

ON

OFF

SP

ON

OFF

SP

X

X

ON

OFF

SP

ON

OFF

SP

ON

OFF

SP

X

X

X

ON

OFF

SP

ON

OFF

SP

ON

OFF

SP

X

X

X

X

ON

OFF

SP

ON

OFF

SP

ON

OFF

0

ON

OFF

X

X

0

ON

OFF

0

ON

OFF

X

X

0

ON

OFF

0

ON

OFF

X

0

ON

OFF

0

ON

OFF

X

0

Setting

* 1

* 1

* 1

Other functions

In addition to the aforementioned, there are alarm hysteresis, automatic return of

display mode and others in the advanced setting group.

Refer to "900-TC8 User's Manual" for details.

For communications details, please refer to "900-TC communications User's

Manual".

Specifications

Input type

*2: Error shown only for"Process value / Set point". Not shown for other status.

Error display (trouble shooting)

When an error has occurred, the No.1 display shows the error code. Take

necessary action according to the error code, referring the table below.

CN1

AT (auto-tuning)

“AT execute”

“ ” flashes

“AT cancel”

Also when AT execution ends, the display

automatically returns to “ ”.

No.1 display

Meaning

Internal circuit error

*2

A/D converter error

*2

Memory error

Input error

*2

(S. Err)

(E111)

(H. Err)

Check the wiring of inputs, disconnections, shorts

and input type.

Turn the power OFF then back ON again. If the display

remains the same, the controller must be repaired. If the

display is restored to normal, then a probable cause can

be external noise affecting the control system. Check for

After the correction of input error, turn the power OFF

then back ON again. If the display remains the same,

the controller must be repaired. If the display is restored

to normal, then a probable cause can be external noise

Action

OFF

Alarm

Control

output

Status at error

OFF

OFF

OFF

Operates

as above the

upper limit.

OFF

OFF

OFF

If the input value exceeds the display limit (–1999 to 9999), though it is within the control range, [[[[ will

be displayed under –1999 and above 9999. Under these conditions, control output and alarm

output will operate normally.

Refer to "900-TC User's Manual" for details of control range.

Set value

0

1

2

Initial setting

group

Communications

setting group

Advanced function

setting group

Default setting : 1

(shaded)

Temperature/ Process Controller

Model

900-TC8

Significance of CAUTIONS

41063-230-01 (2)

Printed In China

English

For detailed operating instructions, please refer to the 900-TC8 User's Manual

(900-UM007A-EN-E).

It can be found online at http://www.ab.com/manuals/.

Indicates information that, if not heeded, could result in injury,

damage to the product, or faulty operation.

ATTENTION

ATTENTION

Devices are Open Type, Listed Process Control Equipment and must be mounted in an enclosure.

More than one disconnect switch may be required to de-energize the equipment before servicing.

Signal inputs are SELV, limited energy.

Caution - To reduce risk of fire or Electrical shock, Do not interconnect the outputs of different Class 2

circuits.

Disconect power to device before installing or servicing.

Do not touch the terminals of controller when voltage is applied.

Do not allow metal fragments or lead wire scraps to fall inside this product. This may cause electric

shock, fire or malfunction.

Do not use this product where subject to flammable or explosive gas.

Never disassemble, repair or modify the product.

The life expectancy of the output relays varies greatly with the switching capacity and other switching

conditions. Always use the output relays within their rated load and electrical life expectancy. If an

output relay is used beyond its life expectancy, its contacts may become fused or burned.

Use copper wire only 24-14 AWG stranded or solid. Torque screws to 0.74 to 0.90 Nm or 6.5 to 8 lb-in.

Only two wires of same type and size per terminal. Correctly set the temperature controller settings to

match the control target. If the settings are not compatible with the control target, the product may

operate in an unexpected manner, resulting in damage to the product or an accident.

To maintain safety in the event of malfunction of the temperature controller, we recommend taking

safety measures, for example, installing an excessive temperature rise prevention alarm on a separate

line. If malfunction prevents control, they may result in an accident.

To reduce the risk of electrical shock or fire, install in a Pollution Degree 2 environment (controlled

environment relatively free of contaminants).

When the product is used under the circumstances or environment below, ensure adherence to

limitations of the ratings and functions. Also, take countermeasures for safety precautions such as

fail-safe installations.

*

Use under circumstances or environment which are not described in the

instruction manual.

*

Use for applications where death or serious property damage is possible and extensive

(1)

Do not use this product in the following:

* Places directly subject to heat radiated from heating equipment.

* Places subject to splashing liquid or oil atmosphere (exceeds NEMA 4X).

* Places subject to direct sunlight, could discolor or cause excessive heat.

* Places subject to dust or corrosive gas (in particular, sulfide gas and ammonia gas).

* Places where intense temperature changes exceed the published ratings.

*

Places subject to icing and condensation.

* Places subject to vibration and large shocks.

(2)

Use/store within the rated temperature and humidity ranges.

Provide forced-cooling if required.

(3)

To allow heat to escape, do not block the area around the product.

Do not block the ventilation holes on the product.

(4)

Be sure to wire properly with correct polarity of terminals.

(5)

Use specified size (M3.5, width 7.2 mm or less) crimped terminals for wiring.

(6)

Do not wire the terminals which are not used.

(7)

Allow as much space as possible between the controller and devices

that generate a powerful high-frequency or surge.

Separate the high-voltage or large-current power lines from other lines, and avoid parallel or

common wiring with the power lines when you are wiring to the terminals.

(8)

Use this product within the rated load and power supply.

(9)

Make sure that the rated voltage is attained within two seconds of turning the power

ON.

(10) When executing self-tuning, turn the load and the unit ON simultaneously, or turn the load ON

before you turn the controller ON.

(11) A switch or circuit breaker should be provided close to this unit.

The switch or circuit breaker should be within easy reach of the operator, and must be marked as

a disconnecting means for this unit.

(12) If you remove the controller from its case, or put the controller into its case, never touch nor

apply shock to the terminals and the electronic parts inside.

Make sure the electronic components and the case are not contacted when inserting the internal

mechanism. Always ensure power is OFF when doing any maintenance on the controller or

associated circuits.

(13) Cleaning: Do not use paint thinner or the equivalent. Use standard grade alcohol to clean the

outside of the product.

(14)

Consider the 2 second delay required for the controller outputs to respond when you

design your control system.

(15)

If an option unit is used in the system refer to its Installation Manual before operating.

NOTICE

: Can be displayed and changed

: Can be displayed

: Can not be displayed and change

to other groups not possible

: Change to

other groups

possible

: Change to

other groups

not possible

• AT in Adjustment group

Designate " : AT execute" to execute

AT and " : AT cancel" to cancel AT.

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

Temperature input shift

(Unit: C or F)

Input shift upper limit

when 2 point input shift

is selected

Input shift lower limit

when 2 point input shift

is selected

Proportional band

Integral time

(Unit: secs)

Derivative time

(Unit: secs)

Dead band

Manual reset value

(Unit: %)

Hysteresis

(cool)

Soak time

SP ramp set value

MV upper limit

MV lower limit

Hysteresis

(heat)

AT execute =

on

AT cancel =

off

Cooling coefficient

Wait band

hys

1.0

chys

1.0

soak

1

sprt

off

ol-h

105.0

ol-l

-5.0

d

40

c-db

0.0

of-r

50.0

c-sc

1.00

wt-b

off

Heater Current 1

Value Monitor

(Unit: A) *7

Leakage Current 1

Value Monitor

(Unit: A) *7

Heater Burnout

Detection 1

(Unit: A) *7

HS Alarm 1

(Unit: A) *7

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

Setting range

Input type

Platinum

resistance

thermometer

Input

Thermocouple

Infrared

Thermosensor

Analog input

Use the following ranges for scaling: –1999 to 9999,

–199.9 to 999.9, Vary Depending on "L", "H" value

Temperature input type

Analog

input type

Setting

Setting range

Input type

Current input

Voltage input

Input

Use the following ranges for scaling: –1999

to 9999, –199.9 to 999.9, –19.99 to 99.99,

–1.999 to 9.999

4 - 20mA

0 - 20mA

1 - 5V

0 - 5V

0 - 10V

• The default is “0” (shaded).

Setting

0

1

2

3

4

• The default is “5” (shaded).

• will be display when a platinum resistance thermometer is mistakenly connected while input

type is not set for it. To clear the display, correct the wiring and cycle the power supply.

Operation group

Adjustment group

Protect group

Input type *3

Scaling upper limit

(only when setting analog input)

Scaling lower limit

(only when setting analog input)

Decimal point

(only when setting analog input)

°C/ °F selection

Set point upper limit

Set point lower limit

In ON/OFF control =

In 2-PID control =

Standard control =

Heating and cooling control =

(Select standard control or heating

and cooling control as required)

Control period (heat)

(Unit: Seconds)

Alarm 2 type: Specified models only

Alarm 3 type: Specified models only

Alarm 1 type: Specified models only

Control period (cool)

(Unit: Seconds)

°C=

°F=

(C stands for Celsius, F for Fahrenheit)

Self-tuning ON =

Self-tuning OFF =

In Reverse operation(heat) =

In Direct operation(cool) =

*3

*4

*3

*4

*3

*4

●Initial setting group

*

3: Refer to the adjoining tables for details of input types and alarm types.

*

4: Applicable only to models with alarm functions.

*

5: Operation is stopped when moved to the initial setting group.

(control/alarm are both stopped.)

*6: The grayed-out parameters may not be displayed according to the model and

parameter.

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

* 6

Transfer output type

Transfer output upper limit

Transfer output lower limit

Linear output type

* 6

* 6

* 6

* 6

Only the value set to the “ : temperature input shift” parameter is

applied to the entire temperature input range. When the process value is

200 °C, the process value is treated as 201.2 °C after input shift if the

input shift value is set to 1.2 °C.

The process value is treated as 198.8 °C after input shift if the input shift

Program pattern

POWER ON

Operation stopped.(control/alarm are both stopped.)

*5

The setting data for the 900-TC-8 is shown here as an

example.

sl-h

1300

sl-l

-200

cntl

onof

s-hc

stnd

st

on

* 6

Pt100

JPt100

K

J

T

E

L

U

N

R

S

B

10 - 70°C

60 - 120°C

115 - 165°C

140 - 260°C

0 - 50mV

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

(No. 1 display flushes

then the control stops)

Hold down

for at least

3 seconds

Hold down

for at least

1 second

Press

(less than 1 second)

Hold and keys

down for at least 1 second

Hold and keys

down for at least

3 seconds

–200 to 850 (°C)

–199.9 to 500.0 (°C)

0.0 to 100.0 (°C)

–199.9 to 500.0 (°C)

0.0 to 100.0 (°C)

–200 to 1300 (°C)

–20.0 to 500.0 (°C)

–100 to 850 (°C)

–20.0 to 400.0 (°C)

–200 to 400 (°C)

–199.9 to 400.0 (°C)

0 to 600 (°C)

–100 to 850 (°C)

–200 to 400 (°C)

–199.9 to 400.0 (°C)

–200 to 1300 (°C)

0 to 1700 (°C)

0 to 1700 (°C)

100 to 1800 (°C)

0 to 90 (°C)

0 to 120 (°C)

0 to 165 (°C)

0 to 260 (°C)

/ -300 to 1500 (°F)

/ -199.9 to 900.0 (°F)

/ 0.0 to 210.0 (°F)

/ -199.9 to 900.0 (°F)

/ 0.0 to 210.0 (°F)

/ -300 to 2300 (°F)

/ 0.0 to 900.0 (°F)

/ -100 to 1500 (°F)

/ 0.0 to 750.0 (°F)

/ -300 to 700 (°F)

/ -199.9 to 700.0 (°F)

/ 0 to 1100 (°F)

/ -100 to 1500 (°F)

/ -300 to 700 (°F)

/ -199.9 to 700.0 (°F)

/ -300 to 2300 (°F)

/ 0 to 3000 (°F)

/ 0 to 3000 (°F)

/ 300 to 3200 (°F)

/ 0 to 190 (°F)

/ 0 to 240 (°F)

/ 0 to 320 (°F)

/ 0 to 500 (°F)

• Up and Down keys

Use the keys to change the values displayed on

the No.2 display.

Each press of key increments or advances the

values displayed on the No.2 display.

Each press of key decrements or returns the

values displayed on the No.2 display.

• Group key

Use this key to change groups:

• Press the key and the key

together for at least 3 seconds to switch

to protect group .

Connections

(The applicability of the electric terminals varies with the type of machine.)

Mounting

Dimensions

Operation indicators

• ALM1: Alarm 1 indicator

Lit when alarm 1 is ON.

• ALM2: Alarm 2 indicator

Lit when alarm 2 is ON.

• ALM3: Alarm 3 indicator

Lit when alarm 3 is ON.

• HA: Heater burnout alarm/Heater Short alarm

indicator

Lit when a heater burnout or Heater Short

alarm has occurred.

• OUT1: Control output 1 indicator

Lit when control output 1 is ON and not lit

when it's OFF.

For a current output, lit except for a 0% output.

• OUT2: Control output 2 indicator

Lit when control output 2 is ON and

not lit when it's OFF.

• STOP: control stop indicator

Lights when event input or “Run/Stop”

is stopped during operation.

During control stop, functions other

than control output are valid.

• CMW: communications writing enable/

disable indicator

Lights when communications writing is

“enabled” and is out when it is

“disabled”.

• °C / °F : temperature unit

The temperature unit is displayed

when the configured display value is

a temperature.

When this parameter is set to “ °C”,

“C ” is displayed, and when set to

“ °F”, “F ” is displayed.

This flashes while ST(Self-Tuning) is

activated.

• : Protection indicator

Lit when Setting Change Protect is

ON (disables the Up and Down Keys).

• MANU: Manual output indicator

Lit when the Auto/Manual Mode is set

• Since the voltage output (control output 1) is not electrically insulated from the internal wiring, one or other of the control output

terminals must be left unearthed when using an earthed (grounded) type thermocouple thermometer. (Connection makes

measurements unreliable due to ground loop currents.) Basic insulation is provided between the voltage outputs (control output 2)

and internal circuits.

Dimensions (mm)

Names of parts on front panel

• No.1 display

Process value or set data symbol

• No.2 display

Set point, set data read-out value or changed

input value

• Mode key

Press this key to change the contents of

the display.

Press this button for 1 s or longer for

reverse scroll.

Adapter

Solderless terminal size: M3.5

In the pack:

• Main unit

• Watertight packing

• Adapter

• Instruction manual

• Terminal cover

* When drawing out from its case, press down the hook and turn a screwdriver to loosen the

screw on the lower part of the front panel.

15

14

13

12

19

18

17

16

11

10

9

8

7

6

2

1

5

4

3

Event Inputs

RS-485

Do not use

A (–)

B (+)

RS-232C

SG

RD

SD

•100-240V AC Type

•24V AC/DC Type

(no polarity)

Input power supply

Alarm 1. HBA/

HSA. input error

Alarm 2

Alarm 3

Alarm output

(relay output)

250V AC 3A

(resistive load)

•Relay output

250V AC 5A

(resistive load)

•Voltage output

12V DC 40mA

•Current output

DC4-20mA

DC0-20mA

load 600 max.

Control output 1

•Triac

relay output

250V AC 3A

(resistive load)

CTs: 900-CT1 or 900-CT3

(available separately)

•2 points

•1 point

Control output 2

CT1

CT2

CT1

–

mA

+

–

+

Analog input

V

CT input

PV

SV

ALM1

ALM2

ALM3

OUT1

STOP

OUT2

CMW

MANU

HA

PV

SV

ALM1

ALM2

ALM3

OUT1

STOP

OUT2

CMW

MANU

HA

•Voltage output:

12V DC 21 mA

TC/Pt multi-input

–

+

B

B

A

PV

SV

ALM1

ALM2

ALM3

OUT1

STOP

OUT2

CMW

MANU

HA

19

15

11

16

17

10

9

8

7

6

5

4

3

2

1

13

18

14

12

Watertight

packing

Terminal

cover

Individual mounting (mm)

Side-by-side mounting (mm)

• Insert the main unit through the mounting hole in the panel (1-8 mm

thickness). Insert the mounting brackets (supplied) into the fixing

slots located on the top and bottom of the rear case.

• Alternately tighten the top and bottom screws on the mounting fixtures

applying equal pressure a little at a time until the rachet rotates freely.

• When more than one machine is installed, make sure that the

ambient temperature does not exceed the specified limit.

Waterproofing is

impossible with

side-by-side installation.

When waterproofing is

required, fit watertight

packing on the backside

of front panel.

120 min

EV2

EV1

-

+

-

+

+0.8

0

92

+0.8

0

92

+0.6

0

45

+1

0

(48 x number of units-2.5)

Power supply voltage

100-240VAC type

24V AC/DC type

Operating frequency

50-60Hz

Operating voltage range

85 to 110% of the rated voltage

Power consumption

Approx. 10VA (AC100-240V)

Approx. 5.5VA (AC24V)

Approx. 4W (DC24V)

Indication accuracy

Thermocouple, platinum resistance

(Ambient temperature: 23 C) thermometer:

(±0.5 % of indication value or ±1 C,

which is greater) ±1 digit max.

Analog

input:

±0.5 % FS ±1 digit max.

Event input

output current: approx. 7 mA per contact.

Contact input

ON:1 k max., OFF: 100 k min.

No-contact input

ON: residual voltage 1.5 V max.,

OFF: leakage current 0.1 mA max.

Control output 1

Relay output: SPST-NO,

250 VAC, 5A(resistive load)

Voltage output: 12 VDC, 40 mA

Current output: 4 to 20 mA DC, and

0 to 20 mA load: 600 max.

Electrical life of relay:

100,000

operations

Control output 2

Voltage output: 12 VDC, 21 mA

Triac output: SPST-NO,

250 VAC, 3A(resistive load)

Electrical life of relay:

1 million operations (Long-life model)

Control method

ON/OFF or 2-PID control

Alarm output

Relay output: SPST-NO, 250 VAC,

3 A(resistive load),

electrical life: 100,000 operations

Ambient temperature

–10 to 55 C

(Avoid freezing or condensation)

Ambient humidity

RH 25 to 85%

Storage temperature

–25 to 65 C

(Avoid freezing or condensation)

Altitude Max.

2,000m

Recommended fuse

T2A, 250V AC, time-lag,

low-breaking

capacity

Weight

Approx. 260g (main unit only)

Degree of protection

Front panel: NEMA4X for indoor use (equivalent to IP66)

Rear case: IP20, Terminal section: IP00

Installation environment

Installation category II, pollution

degree 2 (as per IEC61010-1)

Memory protection

EEPROM (non-volatile memory)

(Number of write operations: 1,000,000)

Operation group should normally

be used during operations.

PV/SP

Set point during

SP ramp

Alarm value 1 *4

Alarm value upper limit 1

*4

Alarm value lower limit 1

*4

Alarm value 2 *4

Alarm value 3 *4

Alarm value upper limit 2

*4

Program start

Alarm value lower limit 2

*4

Heater Current 1

Value Monitor

(Unit: A) *7

Soak time remain

When control start =

When control stop =

Run/Stop

Alarm value upper limit 3

*4

Alarm value lower limit 3

*4

Operation / adjustment

protect

Initial / Communication

protect

Leakage Current 1

Value Monitor

(Unit: A) *7

91

112

96

84.5

11.5

48

44

78

2

Initial setting group enables users to specify their

preferred operating conditions (input type, alarm type,

control method, etc.)

Restricts which parameters can be

displayed or changed, and restricts

change by key operation.

Move to protect group

Adjustment group

Adjustment group is for entering set

values and shift values for control.

Parameter change protect