Rockwell Automation 1102C-PKxx 400A / 600A Vacuum Contactor AC Coil Replacement User Manual

Page 2

42052-091

G. Ushakow

N/A

N/A

N/A

42052

1006490

1

INSTRUCTION SHEET

BULLETIN 1102C 400A/600A VACUUM CONTACTOR

AC COIL REPLACEMENT

2-19-04

Mark Jutz

2-19-04

D. Josef

2-19-04

2

4

REVISION

AUTHORIZATION

DIMENSIONS APPLY BEFORE

SURFACE TREATMENT

H

A

B

C

D

E

F

G

(DIMENSIONS IN INCHES)

TOLERANCES UNLESS

OTHERWISE SPECIFIED

REFERENCE

SHEET

OF

DWG.

B

DR.

CHKD.

APPD.

DATE

DATE

DATE

±

±

±

ANGLES:

.XXX:

.XX:

THIS DRAWING IS THE PROPERTY OF

THE ALLEN-BRADLEY CO. INC.

AND MAY NOT BE COPIED, USED OR

DISCLOSED FOR ANY PURPOSE EXCEPT

AS AUTHORIZED IN WRITING BY

THE ALLEN-BRADLEY CO. INC.

LOCATION : MILWAUKEE,

WISCONSIN

U.S.A.

SIZE

1

2

3

4

5

6

7

8

E - DOC

Coil Replacement (Cont'd)

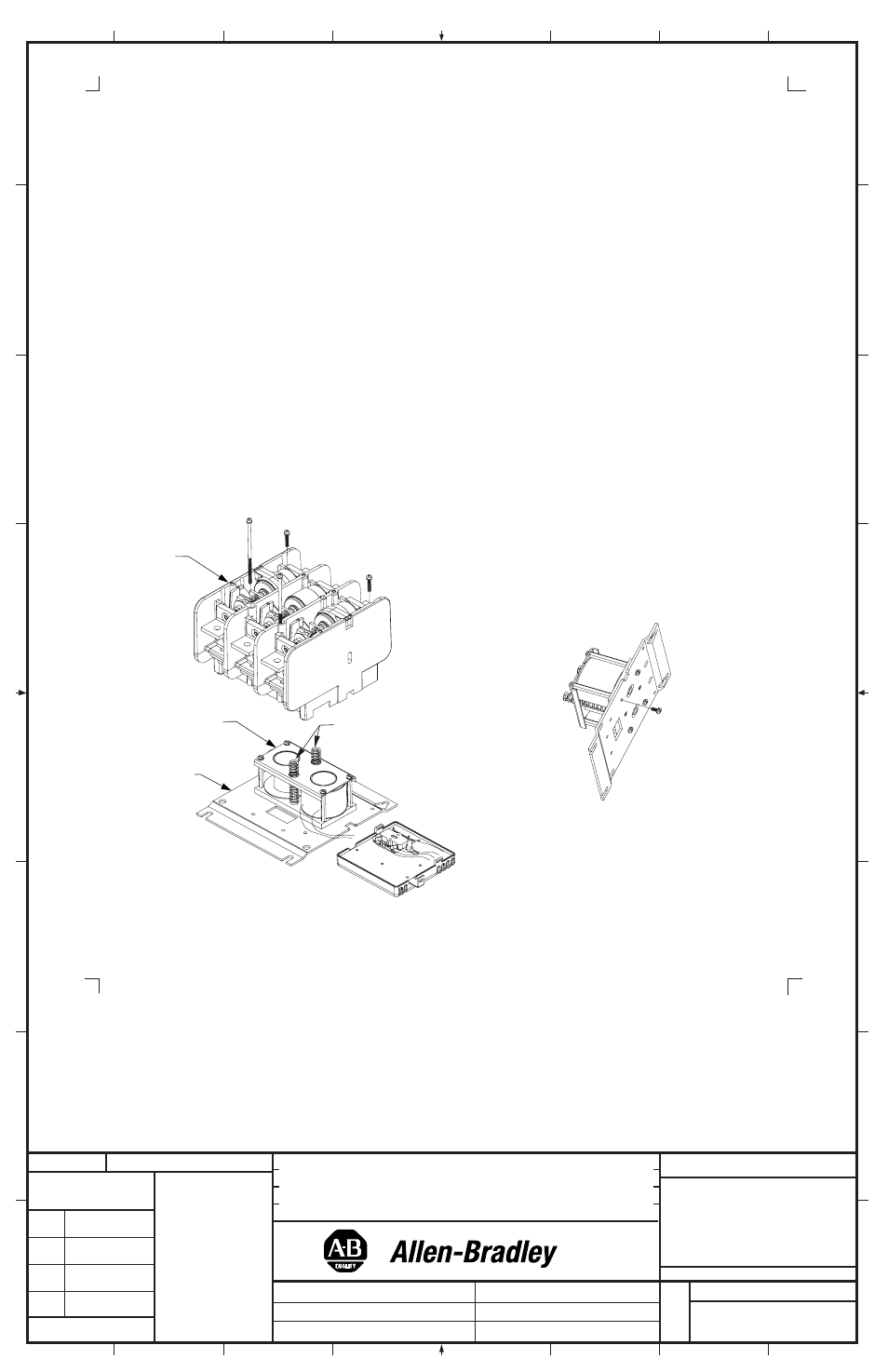

6. While supporting the Main Housing, remove the Main Housing from the Baseplate by removing the (4) screws which

hold the housing to the Baseplate. A long philips-head screwdriver (6 inch or longer) is needed as the four screws are

in deep wells (holes) in the Main Housing. Remove the shorter screws first. Separate the main housing assembly

from the Baseplate and set it aside

(Figure 3).

7. Remove the Return Springs and set them aside (Figure 3). Turn the Base Assembly over and remove the (4)

screws that secure the Coil Assembly to the Baseplate

(Figure 4).

8. Install new Coil Assembly in position using (4) screws (torque to 30 - 45 lb-inches). Replace the Return Springs by

placing them over the spring support pins located within the coil magnet core assembly making sure the return springs

are properly seated and not interfering with any of the control wiring

(Figure 3).

9. Carefully replace the Main Housing assembly loosely, making sure it is orientated correctly. Ensure that no wires

are pinched between housing and baseplate. Carefully locate the magnetic armature poles (the poles sticking down

from the upper housing assembly) into the coil magnet core assembly.

Note: This is a blind operation with careful

side to side motion. Pay close attention to alignment of the locating bosses located at the bottom of the main housing

assembly. To reattach the Main Housing assembly insert the main housing locating bosses into the two mounting

plate holes while compressing the return springs with the Main Housing. Start the four Main Housing screws into the

mounting plate. Tighten the mounting screws equally in a diagonal pattern approximately two turns at a time until

torqued to 28 lb-inches in the same diagonal pattern.

Figure 3

Figure 4

Main

Housing

Coil

Assembly

Baseplate

Return

Springs

(2)