Rockwell Automation 1494V Door Hardware for Small and Intermediate Enclosures - Install Instr. User Manual

1494v, Door hardware for small & intermediate enclosures, Instructions

BULLETIN

INSTRUCTIONS

1494V

DOOR HARDWARE FOR SMALL & INTERMEDIATE ENCLOSURES

CATALOG NUMBERS 1494V-L1, 1494V-LL1, AND 1494V-L2

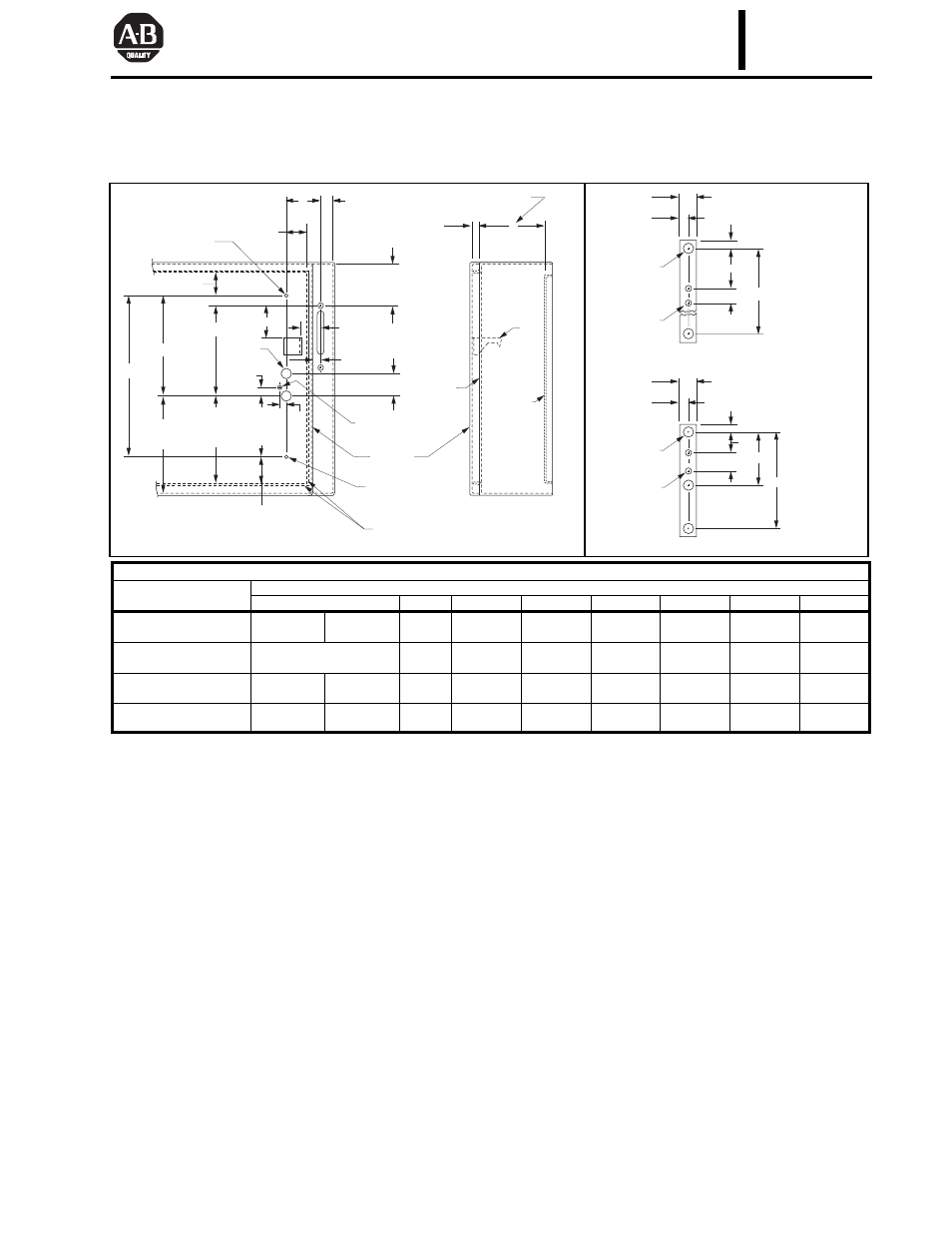

❶ When the Channel Support Kit (Catalog Number 1494V-H4) is not used.

➋ When using the Channel Support Kit.

➌ 1-3/32 in. (27.8) minimum when alternate mounting kit (Catalog Number 1494V-H6) is used.

Guidelines

1.

Use on 16 (1.5) through 10 (3.4) gauge enclosures

with 3/4 in. (19.1) door depth.

2.

Small enclosures: 40 in. (1016) high or less with

2 or 3 point latching.

3.

Intermediate enclosures: 40 in. (1016) through 60 in.

(1524) with 3 point latching.

4.

All drawings in this instruction sheet are for a right

hand flange installation. The left hand flange installa-

tion layout is a mirror image of the right hand flange

installation layout.

INSTRUCTIONS

1.

Check all minimum enclosure and door dimensions

required for installation. See Figures 1 and 2 and the

instruction sheet for the disconnecting means being

installed.

2.

Provide flange slots and holes per the disconnecting

means or operating handle instruction sheet.

3.

Locate the holes in the door to secure the handle

assembly, the top roller assembly, and the bottom

roller assembly (Catalog Number 1494V-L2) when 3

point latching point latching is used.

4.

Locate the door catch using “D” and “G” dimensions.

NOTE: The door catch is made with projections for weld-

ing to the enclosure door. However, holes can be drilled in

the door catch using the projections as centers. Then,

after proper location and using it as a template, corre-

sponding holes can be drilled in the enclosure door. Fas-

ten the door catch with hardware supplied by user. (Seal

as required for your application.)

5.

Establish the length of the locking bar, Figure 3, by

measuring, between the proper holes on the door,

dimension “B”, Figure 1, and adding 5/8 in. (15.9) for

2 point latching door hardware mechanisms and

dimension “M” Figure 1, and adding 5/8 in. (15.9) for 3

point latching door hardware mechanisms.

6.

Determine dimension “A”, Figure 1, by measuring

between the flange and door holes as shown. See

Figure 2 for dimension “J”. Drill and tap the locking

bar as shown in Figure 3.

NOTE: The 1/4 in. (6.35) by 1/2 in. (12.7) standard mill

rectangular locking bar is not supplied with these kits.

NOTE: Dimensions shown in parentheses are in

millimeters

Refer to Dimension "C" on

Disconnecting Means

Instruction Sheet

See the Installation Instructions of the

Disconnecting Means for the

Mounting Depth Range

4" (101.6) Min.

2 Pt.

Latching

2-1/16"

(52.4) Min.

2 Pt.

Latching

3"

(76.2) Min.

3 Pt.

Latching

ONLY

2"

(50.8) Min.

3 Pt.

Latching

17/64" (6.7) Dia.

17/64" (6.7) Dia.

3 Pt. Latching

ONLY

Enclosure Opening

Enclosure

Door

Disconnecting

Means

Mounting

Surface

Operating

Handle

Mounting

Surface

Door

Catch

2-Holes

45/64"

(17.9) Dia.

7/32" (5.6) Dia.

2 Holes

5/16" (7.9) Dia.

2 Holes

#10-24 Tap

1/4"

(6.4)

11/16"

(17.5)

M

B

E

H

N

K

Min.

A

G

F

1-5/8"

(41.3)

3/4"

(19.1)

1/4"

(6.35)

1/2"

(12.7)

5/16"

(7.9)

1/2"

(12.7)

L = A + J

D

1 - 7/16"

(36.5)

1 - 7/16"

(36.5)

B

L

3 Holes

5/16" (7.9) Dia.

2 Holes

#10-24 Tap

1/4"

(6.35)

1/2"

(12.7)

5/16"

(7.9)

1/2"

(12.7)

L = A + J

B

M

L

Figure 1 – Enclosure & Hardware Construction

Figure 3 – Locking Bar for 3 Point Latching

Figure 3 – Locking Bar for 3 Point Latching

Figure 2 – Locking Bar for 2 Point Latching

Figure 2

Disconnecting Means

Operating Handle

Dimensions in Inches

A Min.

D

E Min.

F Min.

G

H

J

K Min.

Short

Cat. No. 1494V-H1

1-1/4

❶

(31.8)

4-3/8

➋

(111.1)

2-7/8

(61.9)

9

(228.6)

21/32

(16.7)

1-3/8

(34.9)

2-17/32

(64.3)

1-11/16

(42.9)

25/32

(19.8)

Long

Cat. No. 1494V-H2

3

(76.2)

3-55/64

(98.0)

11-1/2

(292.1)

25/32

(19.8)

3-55/64

(98.0)

2-21/32

(67.5)

3-7/64

(79.0)

25/32

➌

(19.8)

Flex Cable 14OU-_* with

1494F-P1 Handle

3

❶

(76.2)

6-1/8

➋

(155.6)

2-7/16

(61.9)

10

(254.0)

21/32

(16.7)

1-3/4

(44.5)

2-17/32

(64.3)

1-11/16

(42.9)

25/32

(19.8)

Flex Cable 14OU-_*

with 1494F-P2 Handle

3

❶

(76.2)

6-1/8

➋

(155.6)

2-7/16

(61.9)

11-1/8

(285.8)

21/32

(16.7)

1-3/4

(44.5)

2-17/32

(64.3)

1-11/16

(42.9)

1-1/4

(31.8)