56 attention – Rockwell Automation 1494C-_ _ _ Series 1 Cable Operated Disconnect Switch Kit and Acessories(30A,60A ,100A,200A) User Manual

Page 5

(5)

5

6

ATTENTION:

CHECK FOR PROPER OPERATION. Upon completion of

the installation instructions, no further adjustment of the cable mechanism is

required.

3

5

17

BULLETIN 1494C CABLE OPERATED

DISCONNECT SWITCH KIT INSTALLATION

INSTRUCTION SHEET

1

1015257

1032142

42052-123

OF

N/A

N/A

N/A

REVISION

AUTHORIZATION

DR.

CHKD.

APPD.

DATE

DATE

DATE

E - DOC

LOCATION: MILWAUKEE, WISCONSIN U.S.A.

B-vertical.ai

DWG.

SIZE

SHEET

B

1

2

3

4

5

6

7

8

A

B

C

D

E

F

G

H

REFERENCE

DIMENSIONS APPLY BEFORE

SURFACE TREATMENT

(DIMENSIONS IN INCHES)

TOLERANCES UNLESS

OTHERWISE SPECIFIED

.XX:

.XXX:

ANGLES:

42052

-------------

-------------

-------------

-------------

-------------

-------------

THIS DRAWING IS THE PROPERTY OF

ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED,

USED OR DISCLOSED FOR ANY PURPOSE

EXCEPT AS AUTHORIZED IN WRITING BY

ROCKWELL AUTOMATION, INC.

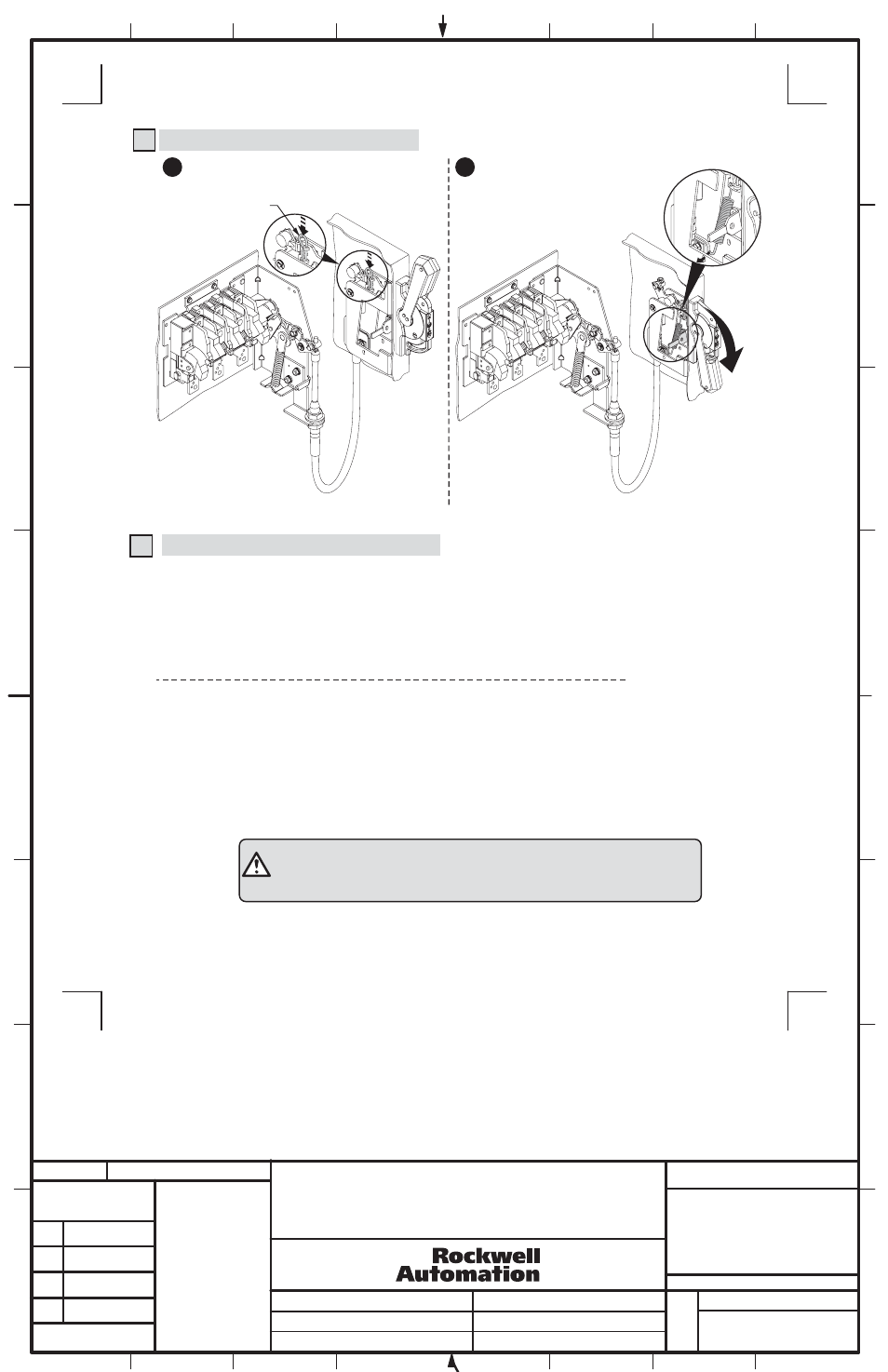

Cable Mechanism Installation (Cont'd)

3

Install hitch pin clip

Turn disconnect handle "OFF" and

install handle mechanism spring

Hitch Pin Clip

Connecting Rod Adjustment Procedure

4

"ON" Position

➊

Move disconnect handle to the "ON" position.

➋

If switch does not fully close, return handle to "OFF" position.

➌

Remove link spring hitch pin and disengage the connecting rod from the primary link.

➍

Turn connecting rod counter-clockwise (1 or more) full turns.

➎

Re-engage connecting rod in primary link of handle, insert hitch pin and re-test

➏

Repeat

➊

-

➎

as necessary.

➐

Re-install link spring.

"OFF" Position

➊

Move disconnect handle to the "OFF" position.

➋

If switch does not fully open, return handle to "ON" position.

➌

Remove hitch pin and link spring, then disengage the connecting rod from the primary link.

➍

Turn connecting rod clockwise (1 or more) full turns.

➎

Re-engage connecting rod in primary link of handle, insert hitch pin and re-test.

➏

Repeat

➊

-

➎

as necessary.

➐

Re-install link spring.

1021899

2